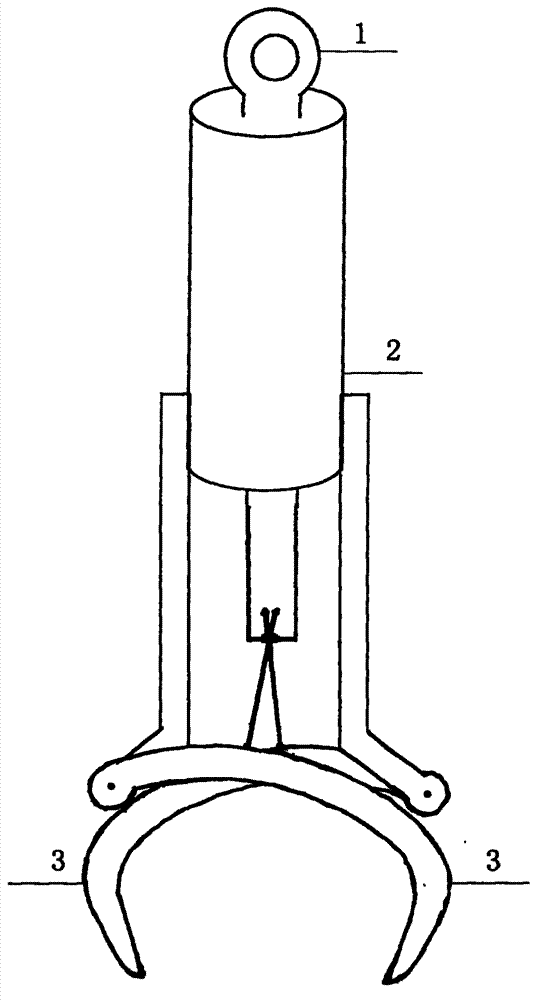

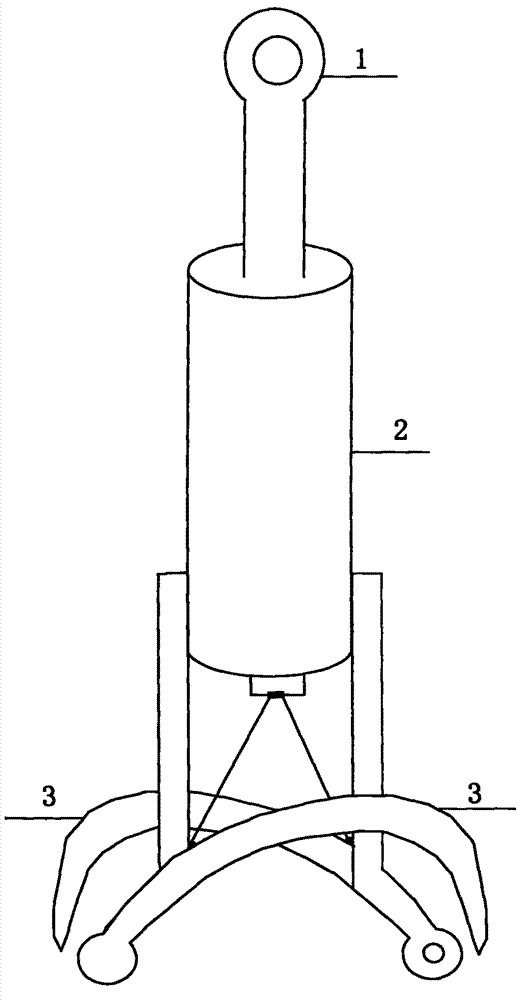

Tiger claw

A tiger-claw and tiger-claw technology is applied in the field of steel loading and unloading construction in steel transfer stations, which can solve the problems of wasting human resources and time, troublesome steel bundling, and aggravating business risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] As shown in the figure, the upper end of the central vertical shaft 1 of the tiger claw is tied to the hanging point rope of the aerial crane. Whether the steel is to be hoisted from the car to the ground or from the ground to the car, as long as the tiger claw is placed on the steel bundle, the aviation If the crane drops 0.20 meters further, the clutch will make the tiger claw 3 catch the steel. When the steel is hoisted to the designated place, the crane should also drop the clutch 2 another 0.20 meters, so that the two tiger claws 2 grasped by the tiger will be separated from the steel, which satisfies the construction requirements. needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com