Fixedly-pasting formwork (formwork frame)

A formwork and formwork technology, applied in construction, building construction, etc., can solve the problems of increasing construction costs, operating risks, dangerous operation errors, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

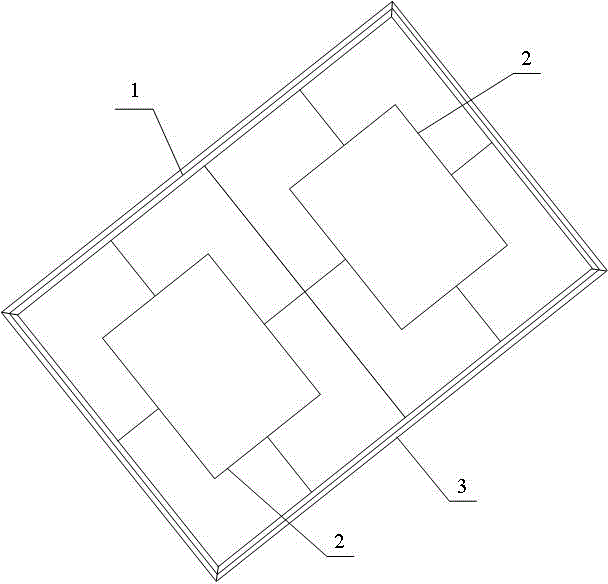

[0008] Such as figure 1 As shown, a fixed template (mould frame), the mold frame is changed from angle steel to plastic steel, the frame 1 of the mold frame is a right-angled square shape, the center is provided with a lining strip 2, and the upper edge of the frame 1 is provided with a wear strip 3.

[0009] The inner diameter of the formwork frame is 6 mm longer and 6 mm wider than the formwork plate. Because there is a mortar joint on the left side and the bottom of it, these two mortar joints are the connection mortar joints between the tiles that have been pasted and the tiles that are now. The thickness of the grout for each tile on the pegboard, the level and balance of each tile with edge grout. The defects of the prior art are solved, the construction is convenient, and a lot of labor and time are saved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com