Large-scale cutting machine with one-step cutting function

A cutting machine, a one-size-fits-all technology, applied in the direction of shearing devices, shearing machine accessories, pipe shearing devices, etc., can solve the problems of aggravating the operation risk of enterprises or individual construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

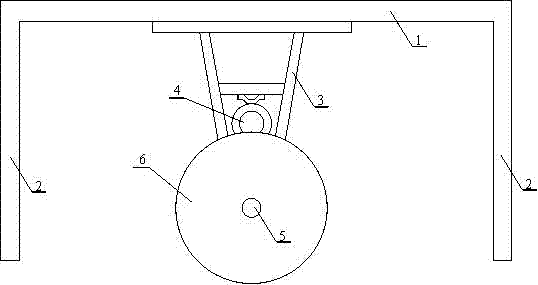

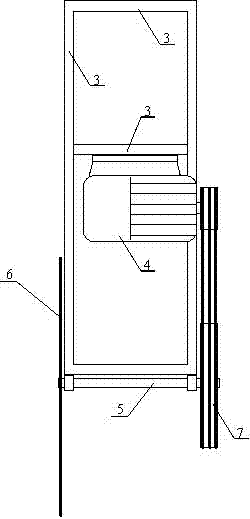

[0009] As shown in the figure, if a large amount of material needs to be cut, it is necessary to use a one-size-fits-all large-scale cutting machine designed in this scheme. A pillar 2 is installed on the indoor wall and connected with the girder 1 by welding. The length of the girder 1 should be more than ten meters at the shortest, and it is better to design the girder on the girder of the house for a new factory building.

[0010] Below the middle of the crossbeam 1 is provided with a hanging machine base 3, in the middle of the machine base 3 is provided with a motor 4, and the bottom end is provided with a shaft 5, one end of the shaft 5 is a cutting blade 6, and the other end of the shaft 5 is a belt pulley 7, the belt Disc 7 links to each other with motor 4 belt disc 7 belts, and cutting machine does not take up a place on the ground, and the material is passed through cutting machine below by cutting bed and has just all been cut on the ground. The defects of the prio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com