Nitrogenous waste liquid burning furnace and denitration method

A combustion furnace and waste liquid technology, applied in the direction of combustion methods, combustion types, incinerators, etc., can solve problems such as difficulties, increased costs, increased materials, etc., to prevent outflow from the furnace, prevent incomplete denitrification, and high efficiency of incineration treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach 〕

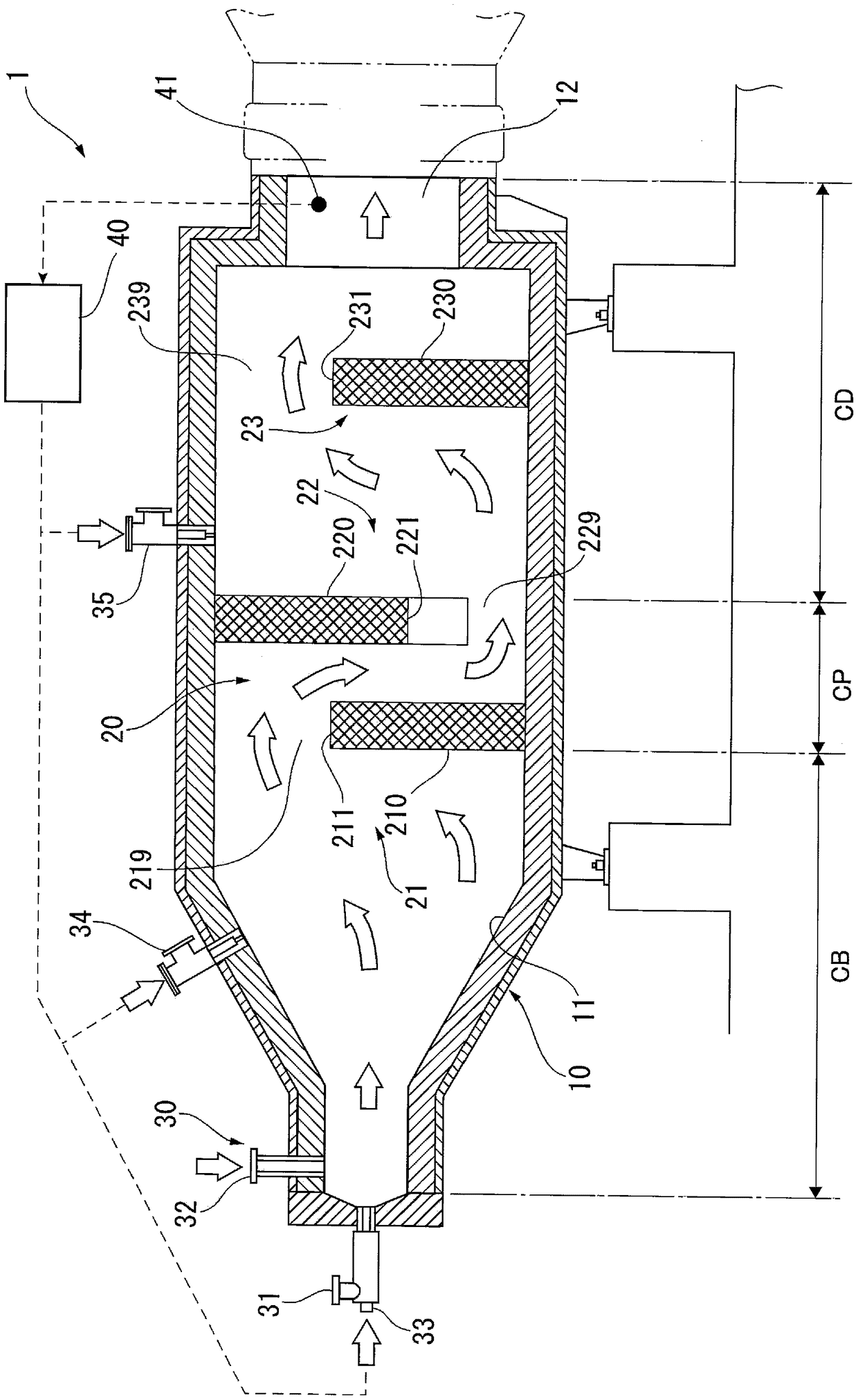

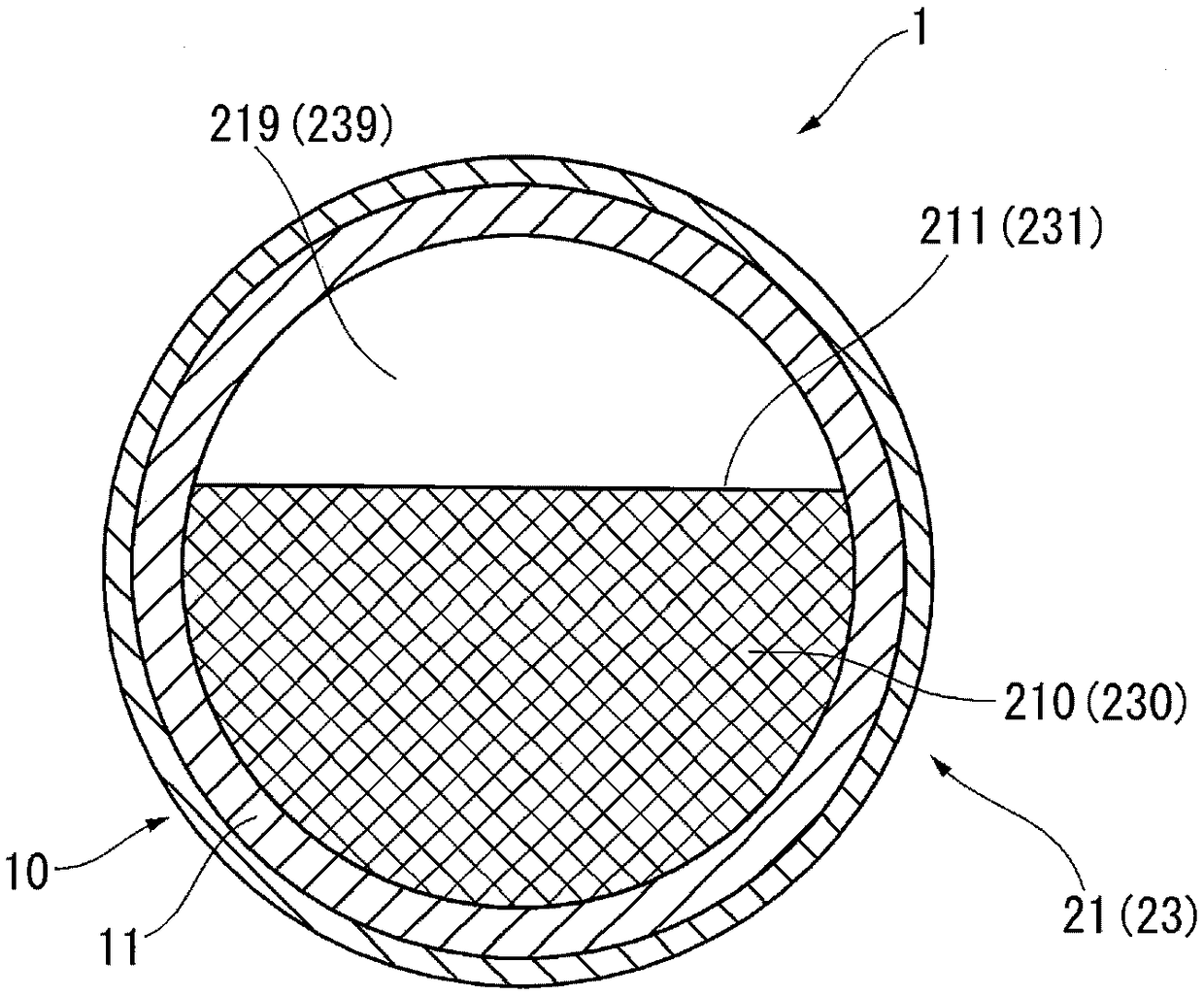

[0051] Hereinafter, a first embodiment of the present invention will be described based on the drawings.

[0052] figure 1 Among them, the nitrogen-containing waste liquid combustion furnace 1 is a combustion furnace for incinerating nitrogen-containing waste liquid, and has a horizontal cylindrical furnace body 10 extending horizontally.

[0053] The shell of the furnace body 10 is formed by iron sheets, and bricks 11 are pasted on the inside as refractory materials. In the middle portion (area CP) of the furnace body 10, a partition structure 20 is provided.

[0054] The interior of the furnace body 10 is partitioned into the upstream side ( figure 1 Left side) of combustion chamber CB and downstream side ( figure 1 Right) Denitration chamber CD.

[0055] The upstream side end of the combustion chamber CB of the furnace body 10 is narrowed into a conical shape, and a burner 30 for combustion is provided at the front end. The burner 30 includes a fuel nozzle 31 , an air ...

no. 2 Embodiment approach 〕

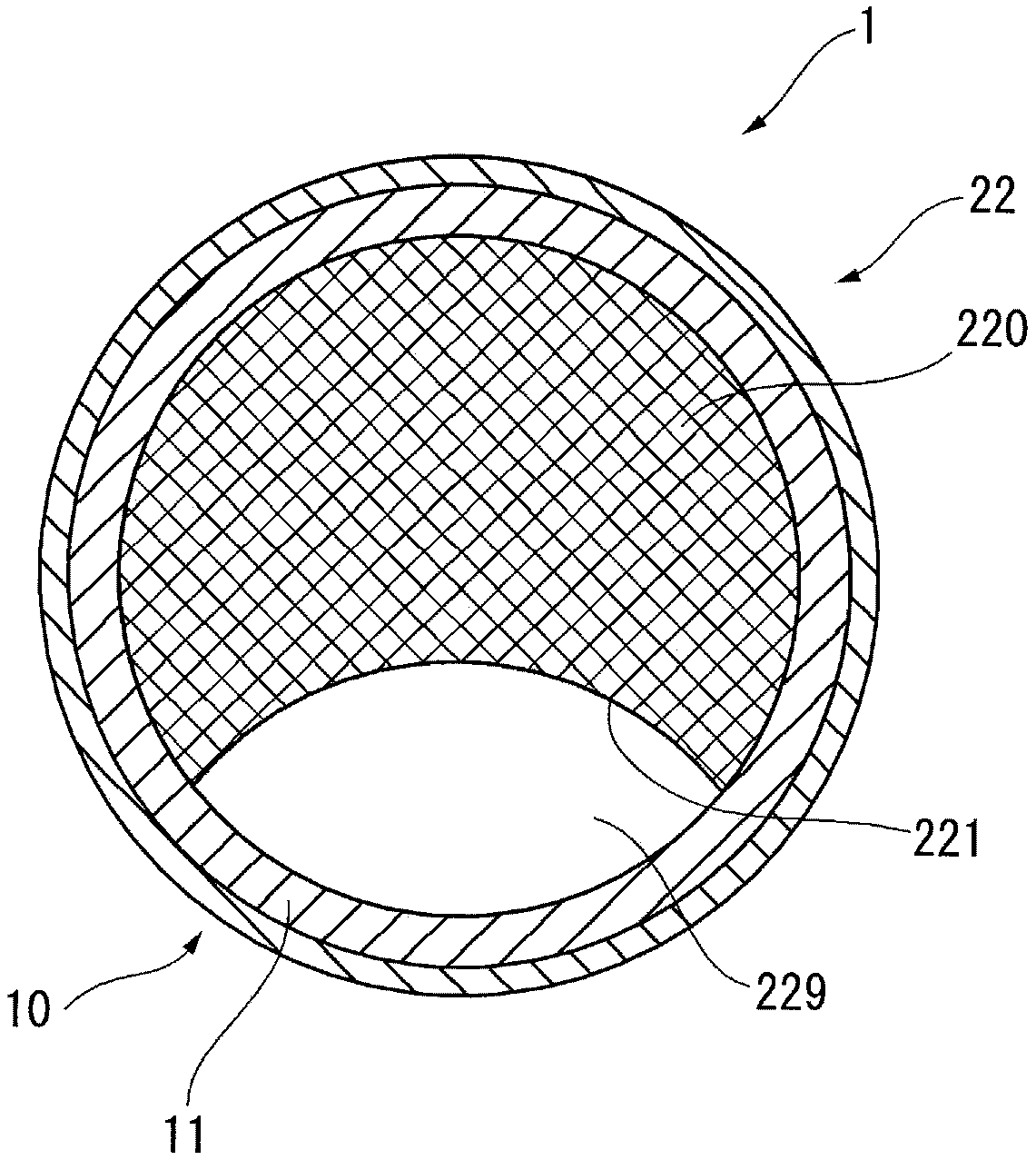

[0106] Next, a second embodiment of the present invention will be described based on the drawings.

[0107] This embodiment is different from the above-mentioned first embodiment in the partition structure 20, but is common to the furnace body 10, the burner 30, and the control device 40. Therefore, description of these common configurations will be omitted, and the partition structure 20A of this embodiment will be described below.

[0108] Figure 5 The horizontal cross-sectional shape of the furnace body 10 of this embodiment is shown in .

[0109] The furnace body 10 has bricks 11 attached to its substantially cylindrical inner surface, and is partitioned into a combustion chamber CB on the upstream side and a denitration chamber CD on the downstream side by a partition structure 20A provided in the region CP.

[0110] In the furnace body 10 , as in the above-mentioned first embodiment, a high-temperature gas is generated by the burner 30 in the combustion chamber CB, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com