Method for manually applying pressure to pressure chamber

A pressure chamber and pressure technology, which is applied to water boiling appliances, cooking utensils, beverage preparation devices, etc., can solve the problems of brewing milk powder, inability to use each other, and odors, and achieves low cost, long service life, simple and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

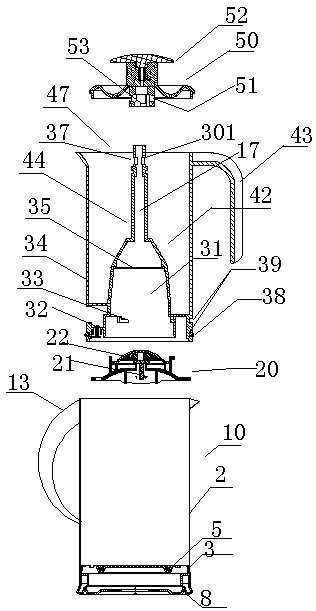

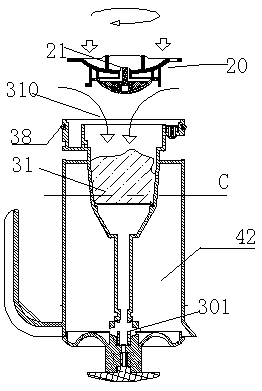

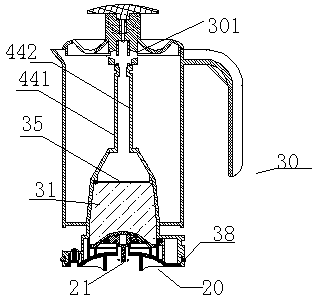

[0060] see Figure 1-Figure 7 , the manual pressure chamber pressure method, the main body includes a brewing collection chamber assembly 30, a brewing chamber piston container 34, a hot water container 10, and a sealed pressure chamber 15, characterized in that:

[0061] At least one brewing chamber piston container 34 is arranged on the brewing collection chamber assembly 30, and at least one piston brewing chamber 31 is arranged on the brewing chamber piston container 34, and the piston brewing chamber 31 is used for containing and dissolving Material; the upstream of the piston brewing chamber 31 is provided with a water inlet 16, and the downstream of the piston brewing chamber 31 is provided with a first filter screen or a filter hole (35), or a water outlet 37;

[0062] The periphery of the brewing collection chamber assembly 30 is sleeved up an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com