Method for assembling a fringe-beam motor tricycle frame device

An assembly method and the technology of side three wheels, applied in the direction of motor vehicles, bicycles, bicycle accessories, etc., can solve the problems of less oil storage, poor straight-line driving performance, poor ride comfort, etc., and achieve simple structure and ingenious design , the effect of using the effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

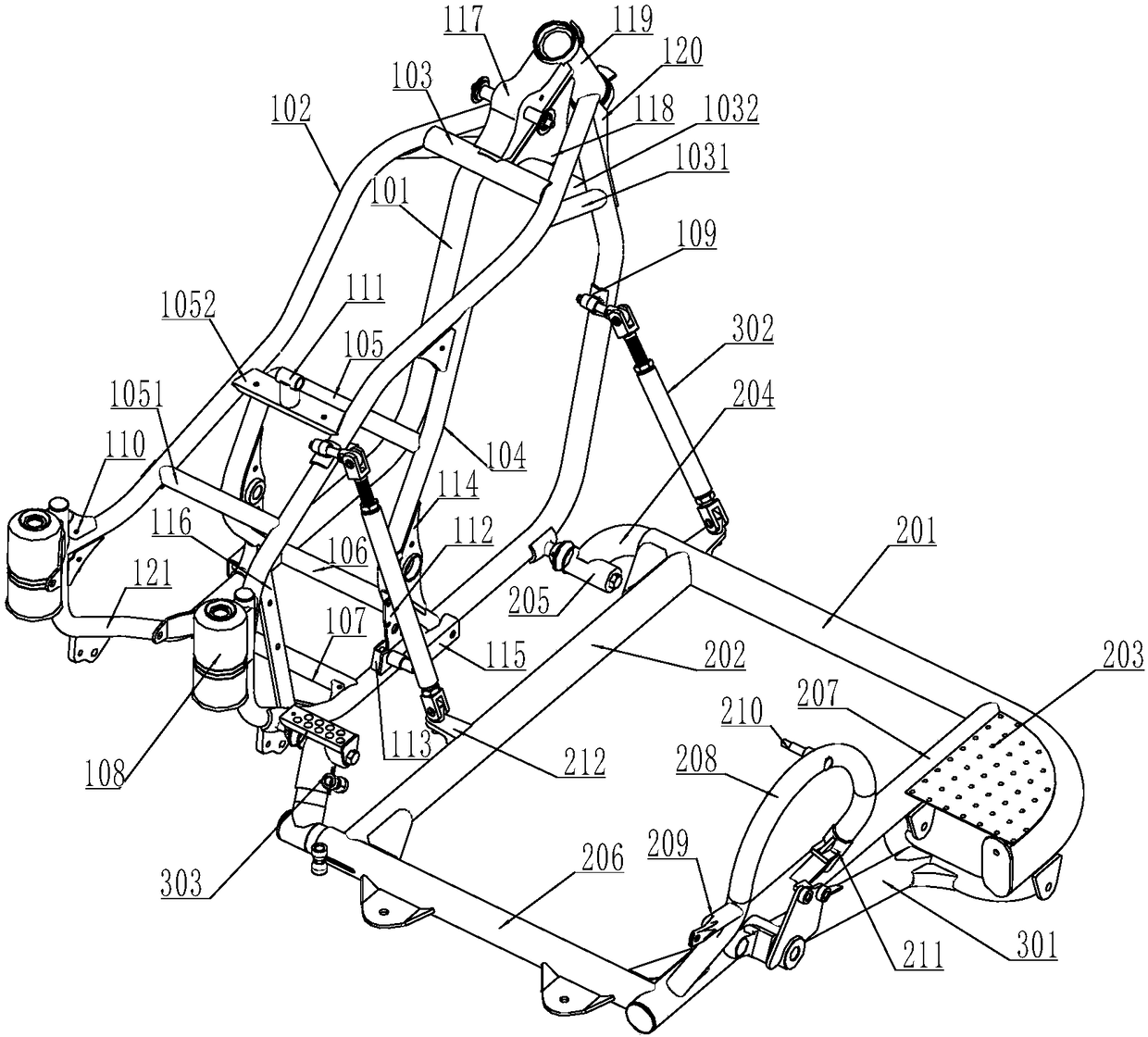

[0014] The structure of the main frame is as follows: a pair of engine mounting tubes 101 are parallel to each other, the side view structure of the engine mounting tubes 101 is L-shaped, and the included angle between the horizontal short tube and the vertical long tube of the engine mounting tube 101 is 110~ 130 degrees, the connection between the short horizontal pipe and the long vertical pipe of the engine installation guarantee pipe 101 is arc-shaped, and one end of the short horizontal pipe of the engine installation guarantee pipe 101 and one end of the short horizontal pipe of the rear frame pipe 121 of the vehicle frame Corresponding to the fit, the rear frame tube 121 of the vehicle frame is composed of an inclined tube arranged between the horizontal short tube and the vertical short tube, and the included angle between the horizontal short tube and the inclined tube of the frame rear frame tube 121 is 150-160° The connection between the horizontal short pipe and th...

Embodiment 2

[0017]A pair of frame main pipes 102 are placed facing each other, and the welding port between the upper ports of the pair of frame main pipes 102 is inclined upward to the front fork riser 119. Fixed, the lower ports of a pair of engine installation securing tubes 101 are correspondingly inserted into the lower ports of a pair of vehicle frame rear frame tubes 121, the upper ends of the vehicle frame rear frame tubes 121 are correspondingly fixed with the lower ends of the vehicle frame main pipe 102, and the engine mounting securing tubes 101 The outer periphery of the lower end is welded with the lower end of the middle support tube 104, the middle bend of the middle support tube 104 is welded with a crescent-shaped fixing plate 114, and the connection between the middle support tube 104 and the engine installation guarantee tube 101 is welded with a reinforcing block near the rear frame tube 121 of the vehicle frame 110, the upper end of the intermediate support pipe 104 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com