Code zero-clearing mechanism of coded lock

A combination lock and clearing technology, applied in the field of combination locks, can solve problems such as time-consuming, troublesome use of combination locks, easy to forget, etc., and achieve the effect of improving the safety and convenience of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

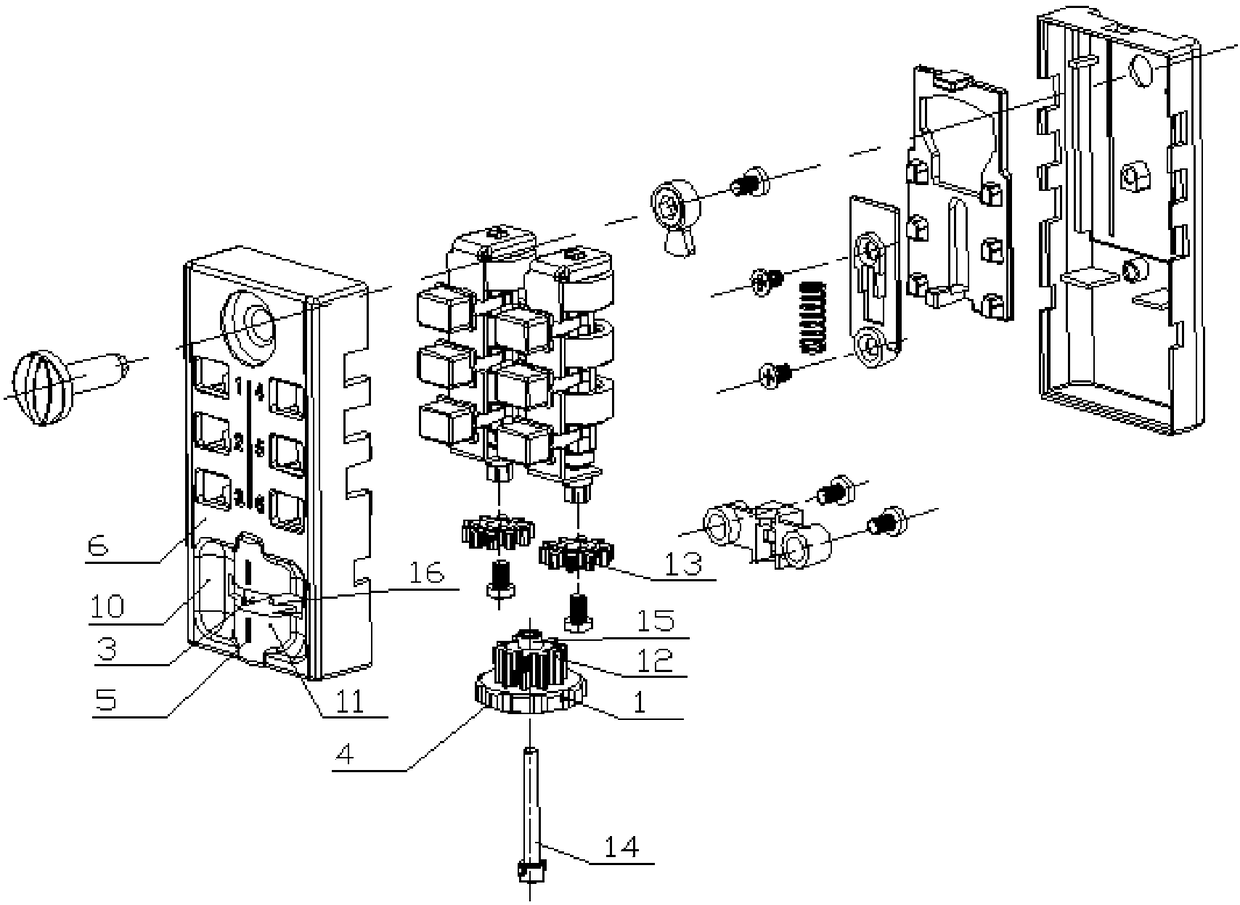

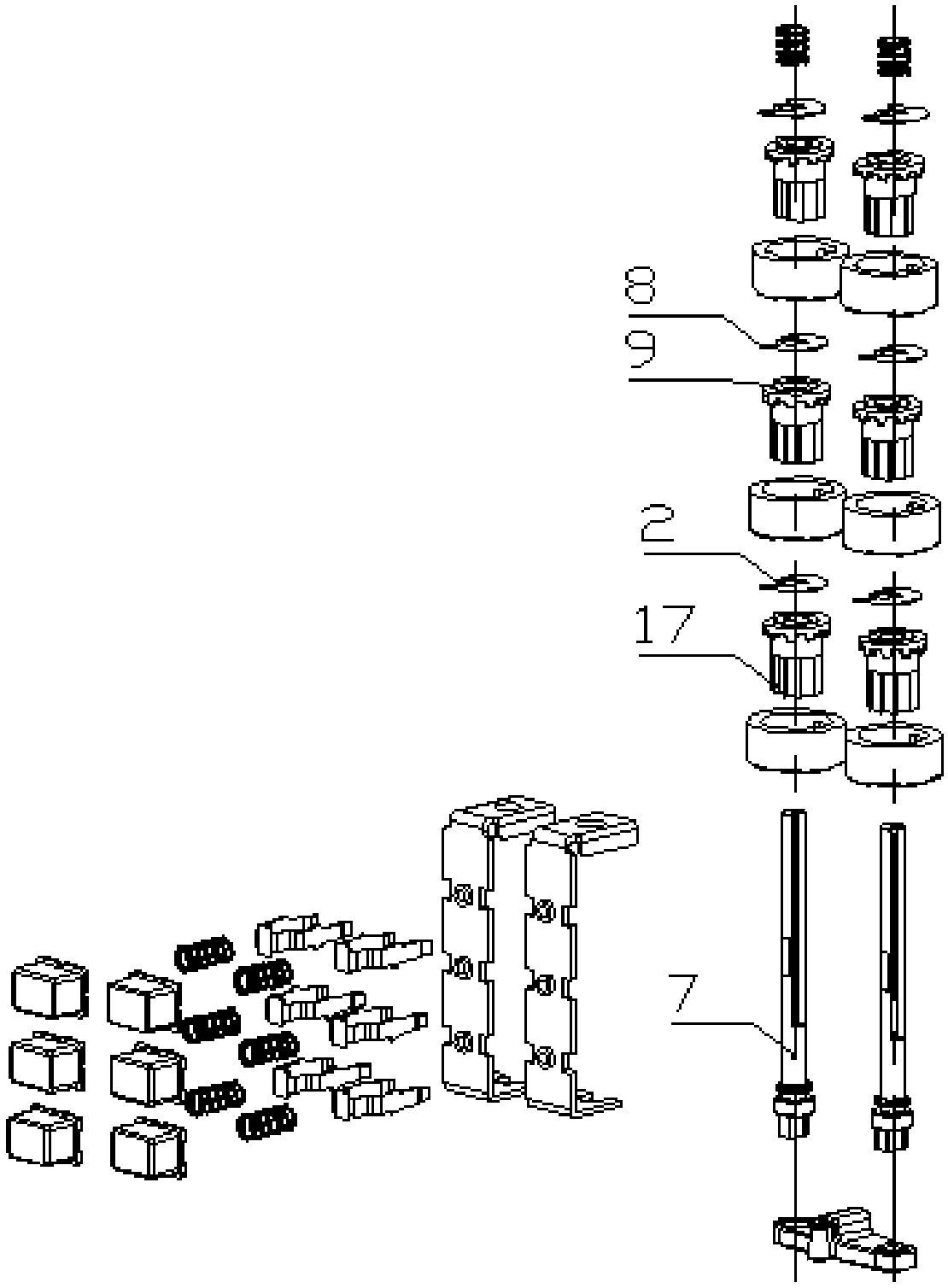

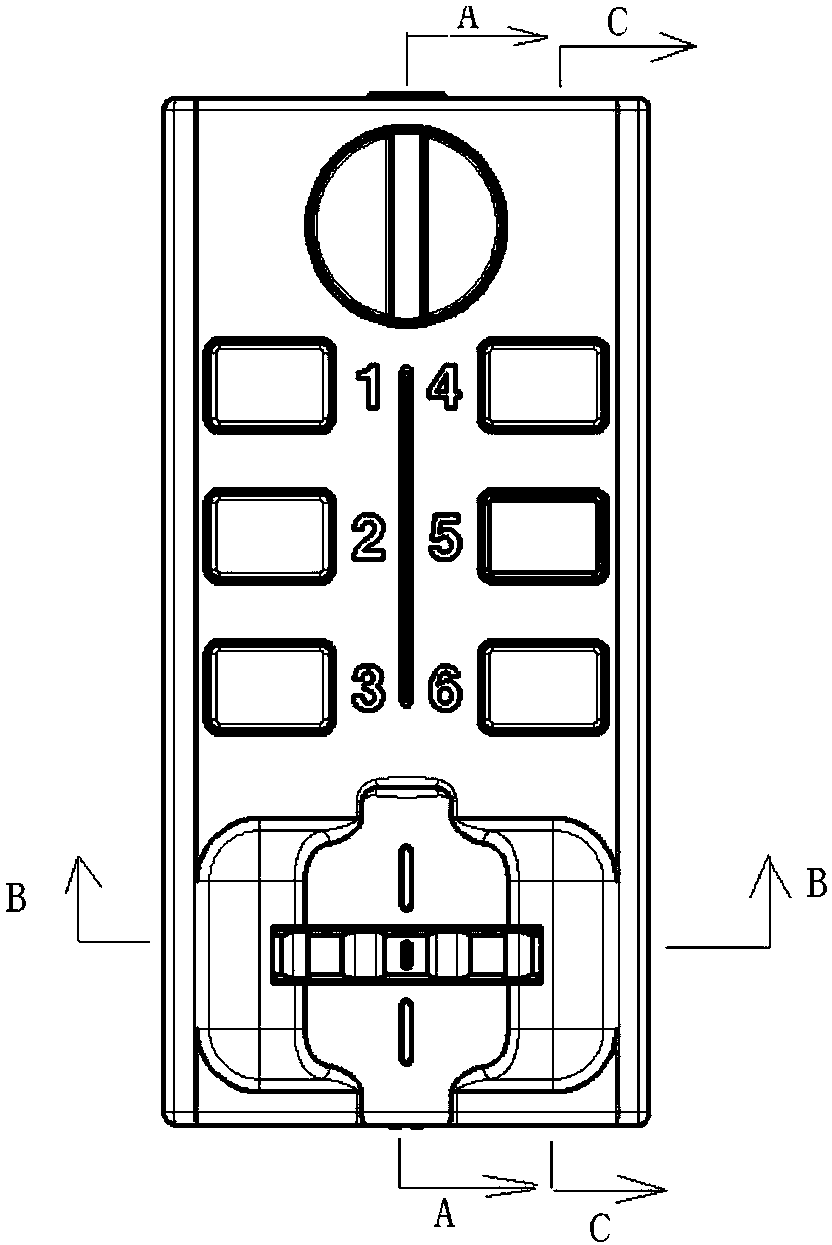

[0018] Embodiment: a password clearing mechanism of a combination lock, comprising a zero clearing wheel 1 and a homing piece 2, the zero clearing wheel 1 is rotatably arranged on the lock housing 6, and the rotating shaft of the zero clearing wheel 1 is connected to the The central axis 7 is arranged in parallel, and a hollow part 3 is provided on the surface of the lock case 6 of the combination lock. A part of the outer side wall of the reset knob passes through the hollow part 3 and is exposed outside the combination lock. A reset mark 4 is provided on the reset wheel 1. A standard mark 5 is provided on the outer surface of the lock housing 6, and the zero clearing mark 4 can be directly opposite to the standard mark 5. The zero clearing wheel 1 is synchronously driven with at least one central axis 7 of the combination lock, and several homing pieces 2 are respectively The circumferential stop is set on the central axis 7 of the combination lock, and each homing piece 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com