Full-field Quantitative Statistical Distribution Characterization Method of Precipitated Phase Particles in Metallic Materials

A technology of statistical distribution of metal materials, applied in particle and sedimentation analysis, material analysis through optical means, material analysis, etc., can solve problems such as inhomogeneity and low efficiency of manual image modification, and achieve large field of view and statistical The data is accurate and reliable, eliminating the effect of incomplete statistics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

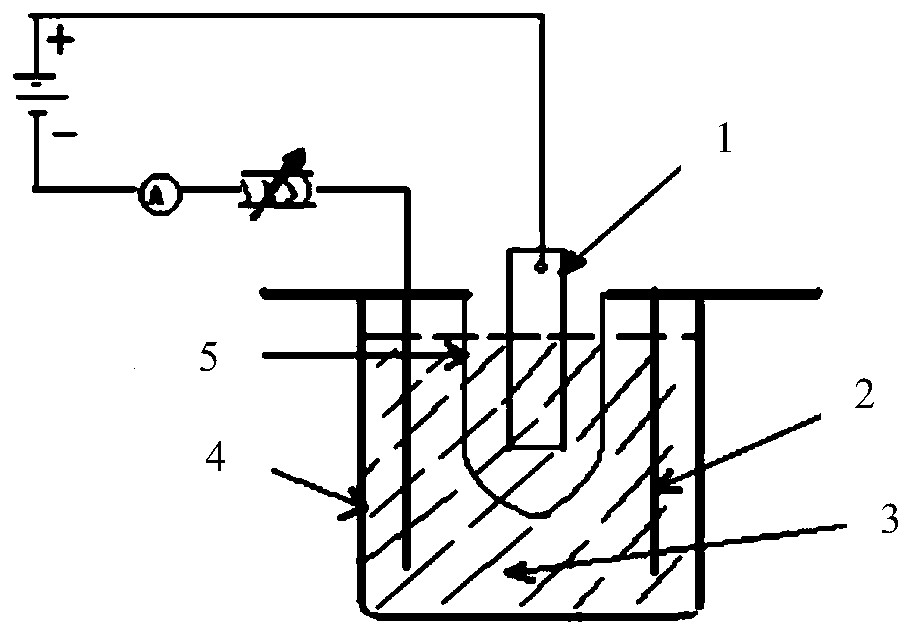

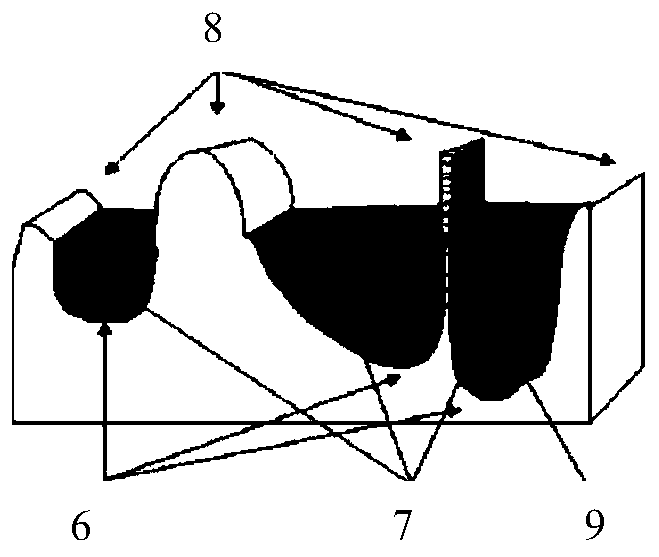

Method used

Image

Examples

Embodiment

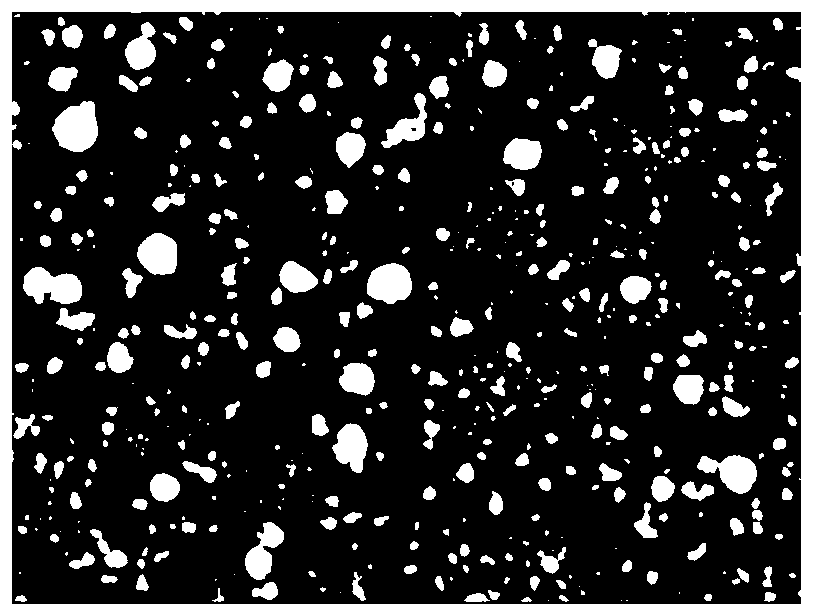

[0086] This example is a nickel-based superalloy for aero-engine turbine disks. This precipitation-hardening nickel-based superalloy is a key heat-resistant material for manufacturing aero-engines, gas turbines, nuclear reaction equipment, etc., and its development level has become an important symbol of a country's aviation industry level. . With the improvement of engine thrust-to-weight ratio and performance requirements, the turbine inlet temperature is constantly increasing, and higher requirements are placed on the temperature of the turbine disk alloy. There are differences, especially the cooling rate will form a gradient distribution on the thickness section, resulting in differences in the number, size and distribution of the γ' phase in different regions, so the γ' of nickel-based superalloys in a large range must be Only by performing quantitative statistical distribution characterization of phases can we obtain a more reliable law of the influence of γ' relative t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com