Intelligent ejection-type rice seedling throwing machine capable of realizing orderly rice seedling throwing and control method of machine

An intelligent catapult and seedling throwing machine technology, which is applied in planting methods, transplanting machinery, applications, etc., can solve the problems of complex structure, seedling throwing density and distance of throwing seedlings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

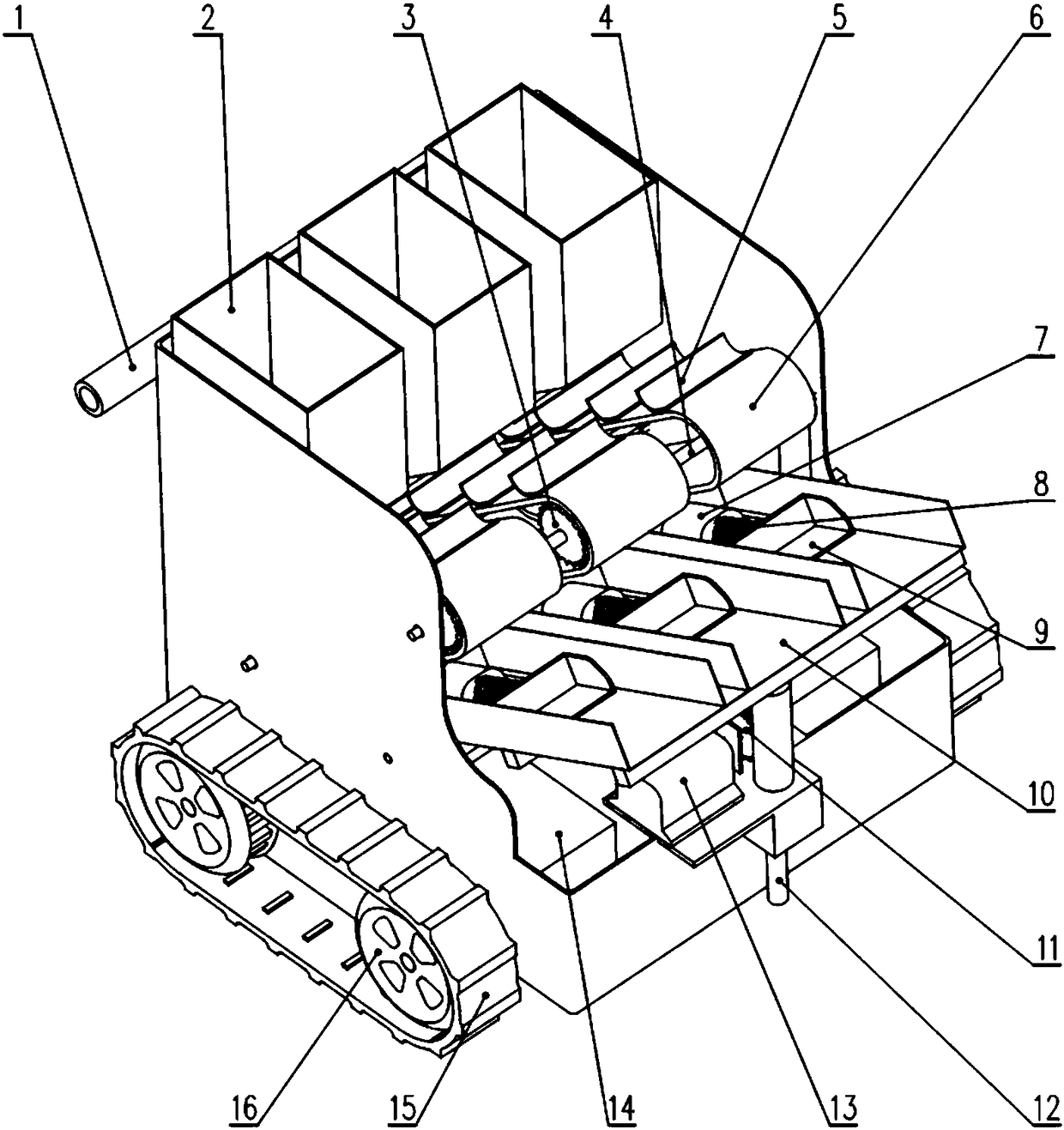

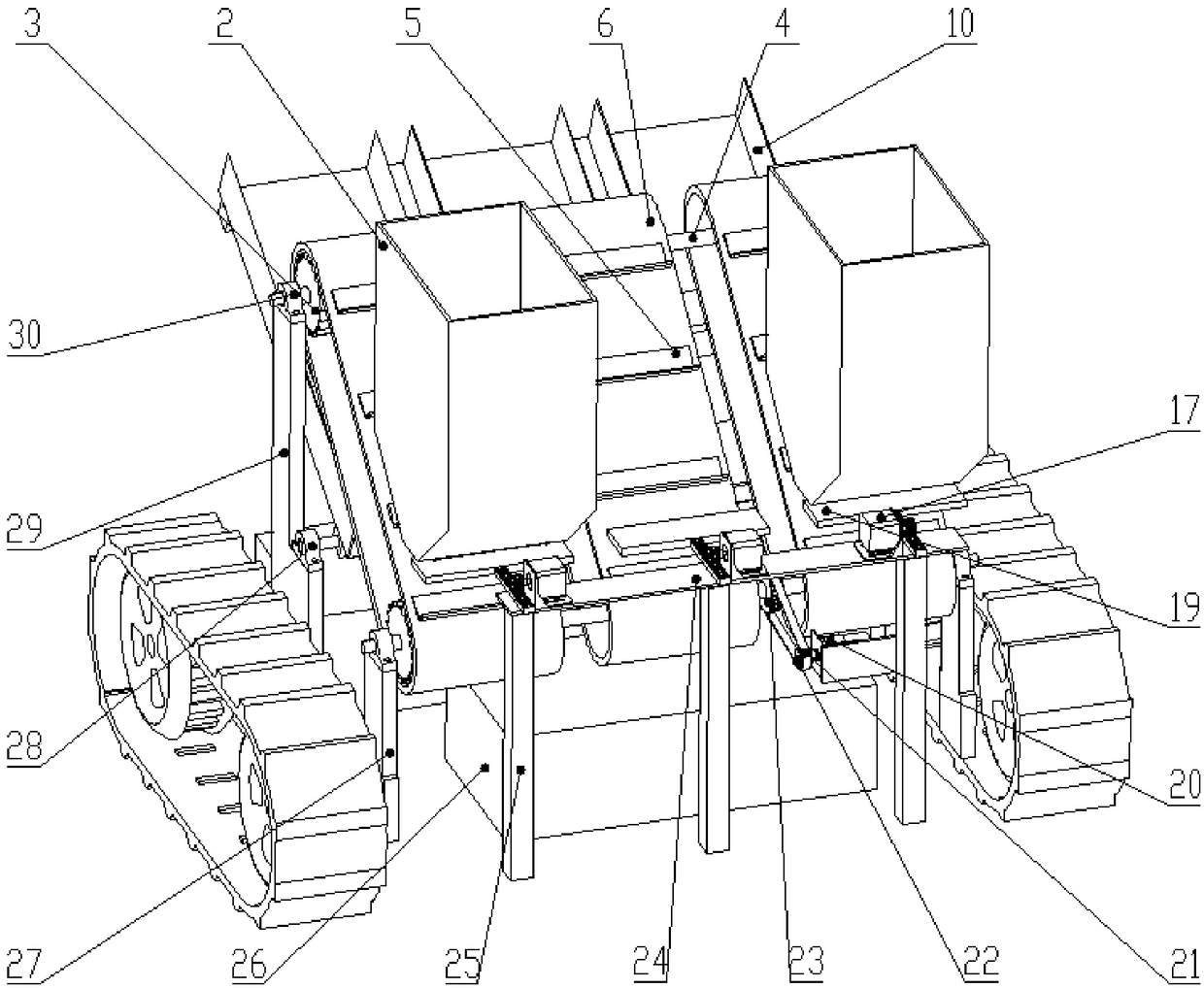

[0032] The structural principle, working process and specific implementation methods of the present invention will be further described below in conjunction with the accompanying drawings.

[0033] see figure 1 and figure 2 , The rice throwing machine provided by the present invention includes a frame 1, a blanking mechanism, a transmission mechanism, an ejection mechanism, a control unit, and a driving mechanism of the rice throwing machine; one or more of the blanking mechanisms can be arranged side by side according to planting needs.

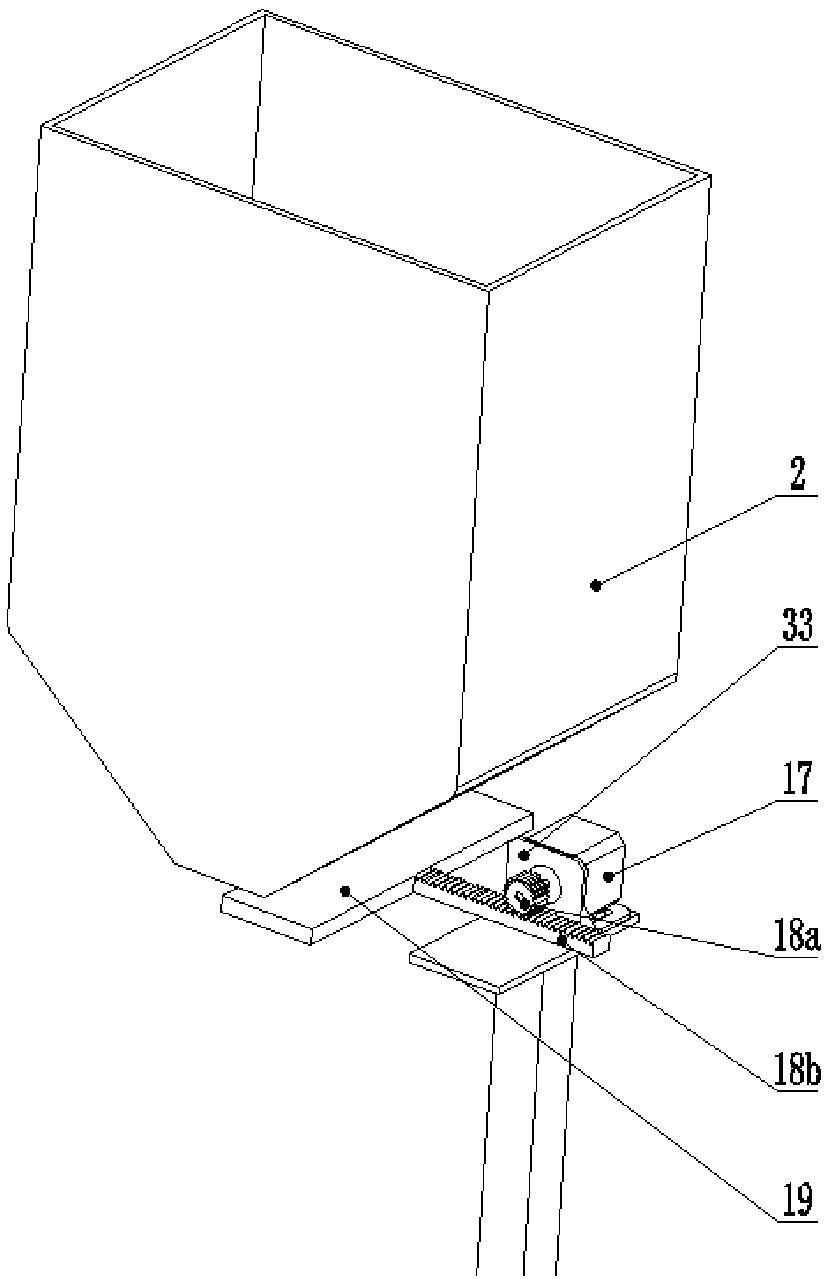

[0034] From figure 2You can see the installation method of each mechanism and the arrangement form of each part; the blanking mechanism is arranged at the rear and upper part of the seedling throwing machine; the blanking mechanism includes the blanking barrel 2, the blanking switch baffle 19 and the switch baffle driving mechanism; The switch baffle driving mechanism comprises a first stepper motor 17, a switch baffle drive gear 18a and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com