Tight sandstone gas reservoir sensitivity experiment evaluation method

A tight sandstone and evaluation test technology, which is applied in the preparation of test samples, measurement devices, suspension and porous material analysis, etc., can solve problems such as seepage difficulties, blocked pore throats, and inconformity with the seepage law of gas reservoirs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

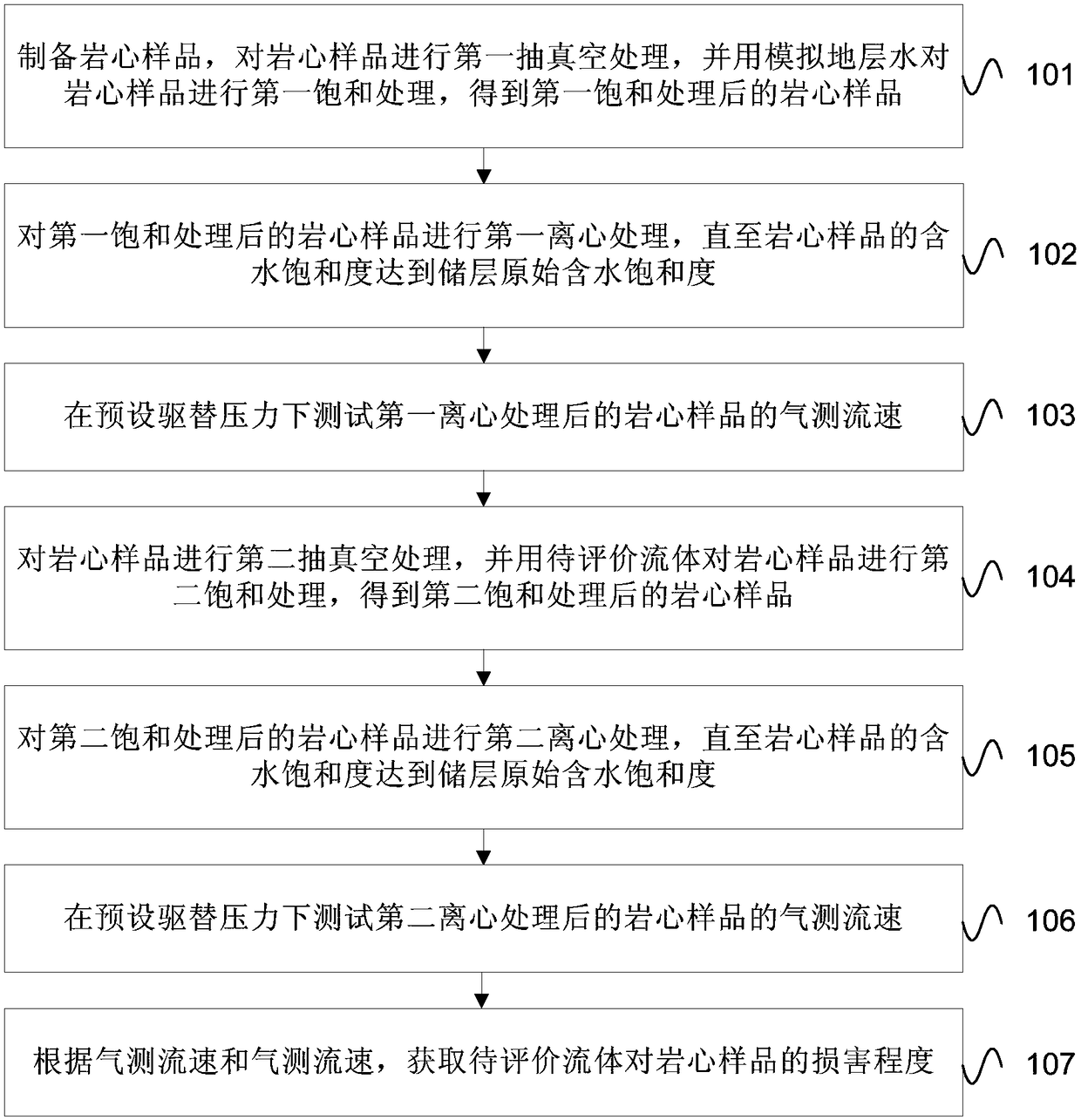

[0052] figure 1 It is a flow chart of Embodiment 1 of the tight sandstone gas reservoir sensitivity evaluation test method of the present invention, as figure 1 As shown, the tight sandstone gas reservoir sensitivity evaluation test method of this embodiment includes:

[0053] Step 101, preparing a core sample, performing a first vacuuming treatment on the core sample, and performing a first saturation treatment on the core sample with simulated formation water, to obtain a core sample after the first saturation treatment.

[0054] Specifically, in this embodiment, a plunger-shaped core sample is drilled, the length of the core sample is greater than 4 cm, the core sample is washed with oil and salt, and the core sample is dried, and finally the dried core sample is obtained .

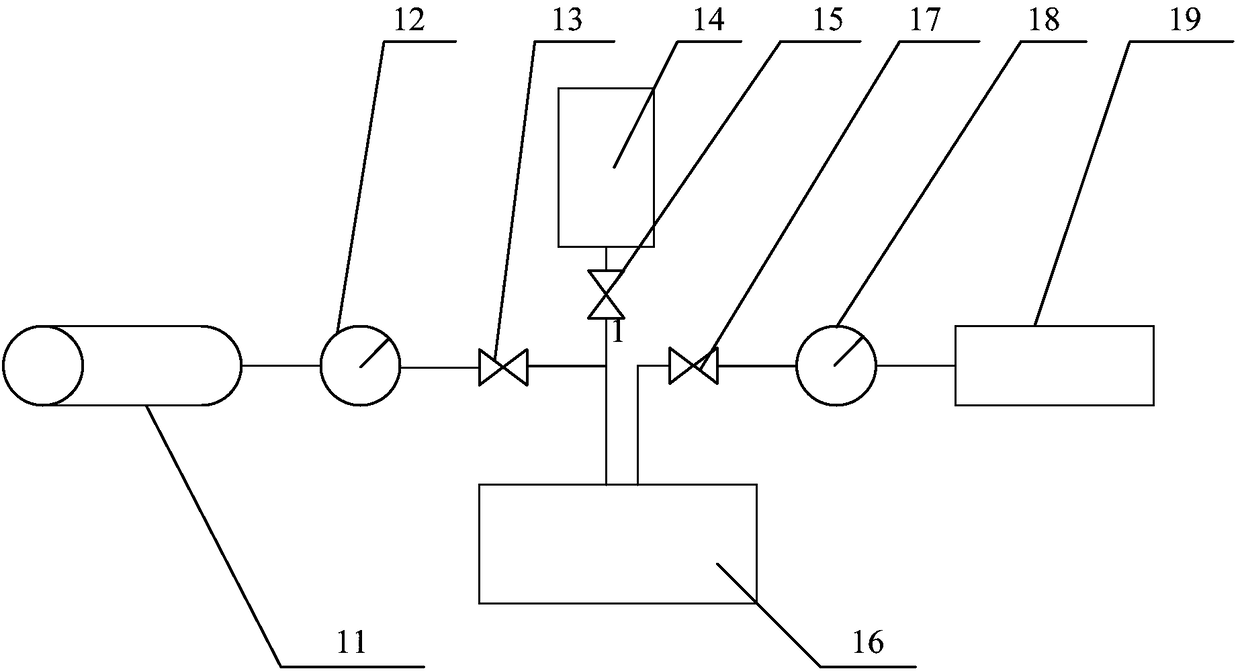

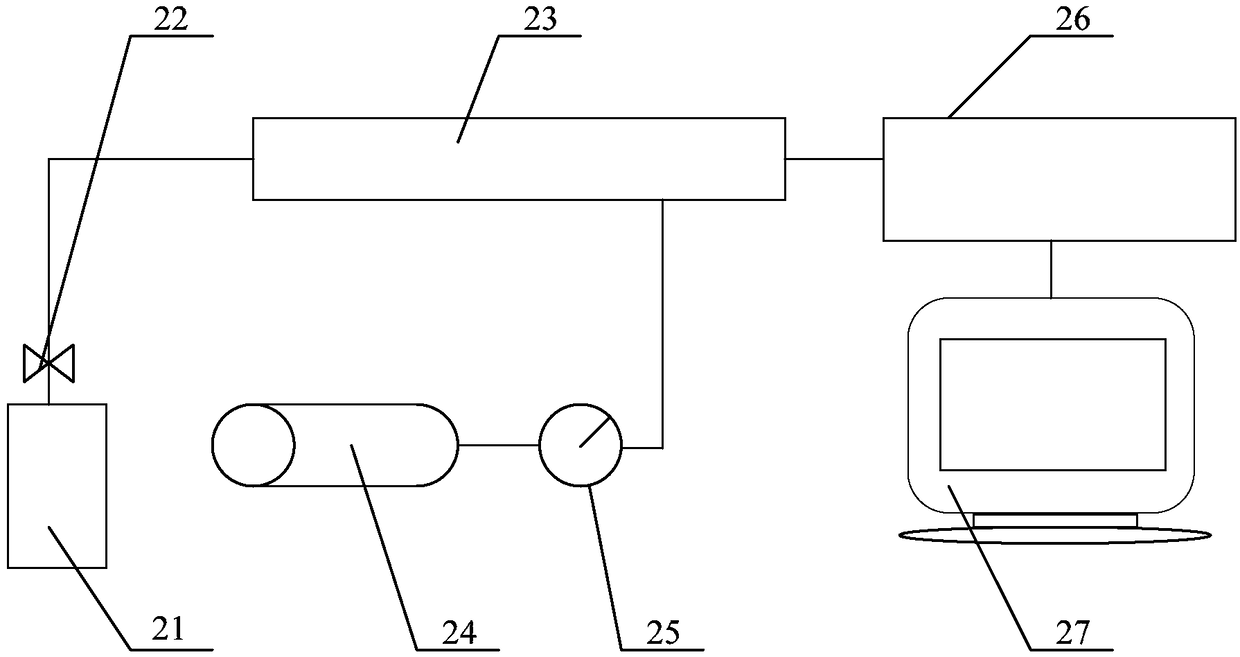

[0055] After the prepared core sample is obtained, the core sample is placed in an evacuation-high pressure saturation device for evacuation, high pressure and saturation treatment. Combine below ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com