Three-dimensional helical structure cell sorting micro-fluidic chip and manufacturing method thereof

A microfluidic chip and helical structure technology, applied in the field of microfluidics, can solve the problems of complex operation, inability to meet the rapid sorting process of large-volume samples, and discounted sorting efficiency, so as to increase the processing throughput and meet the needs of rapid sorting. Select the effect of preprocessing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

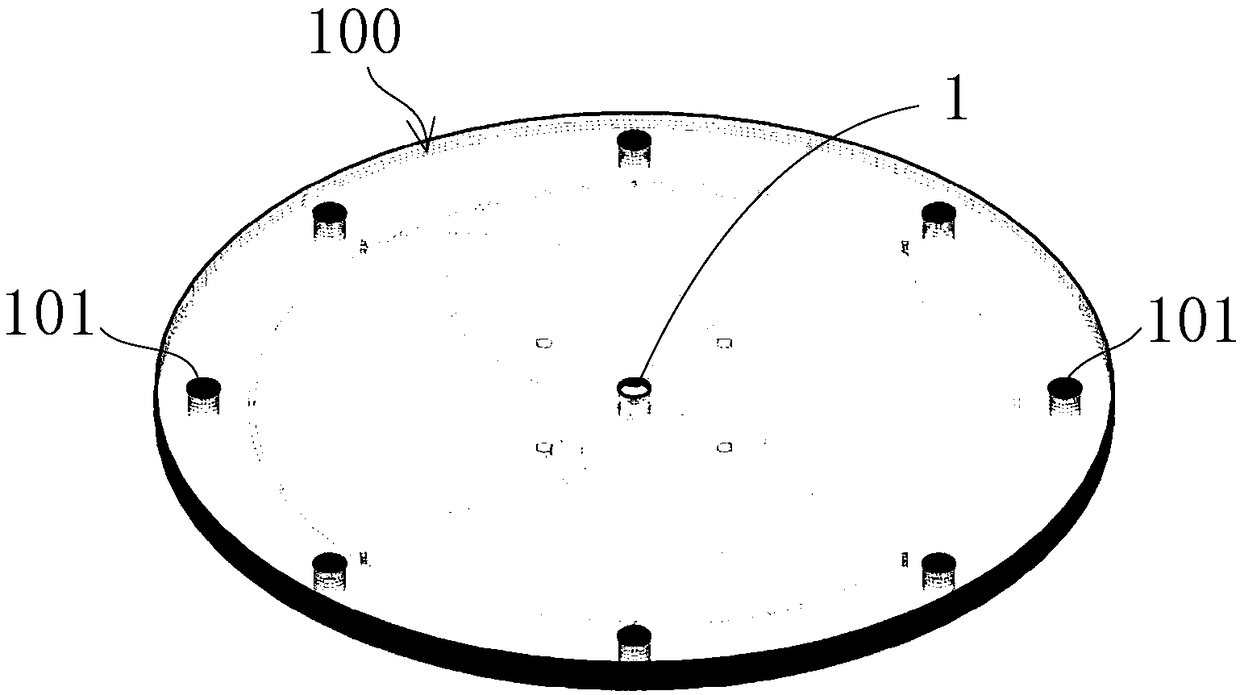

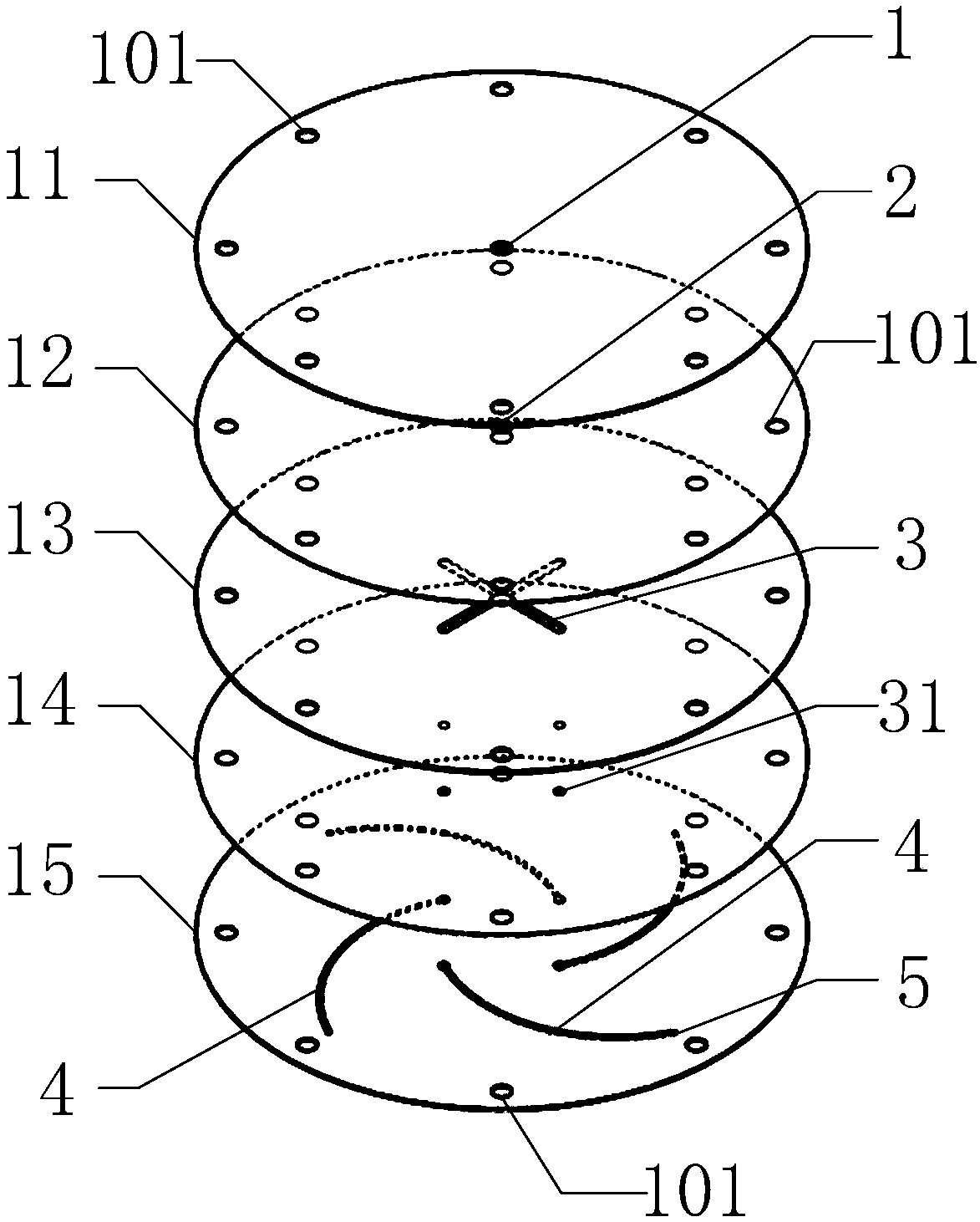

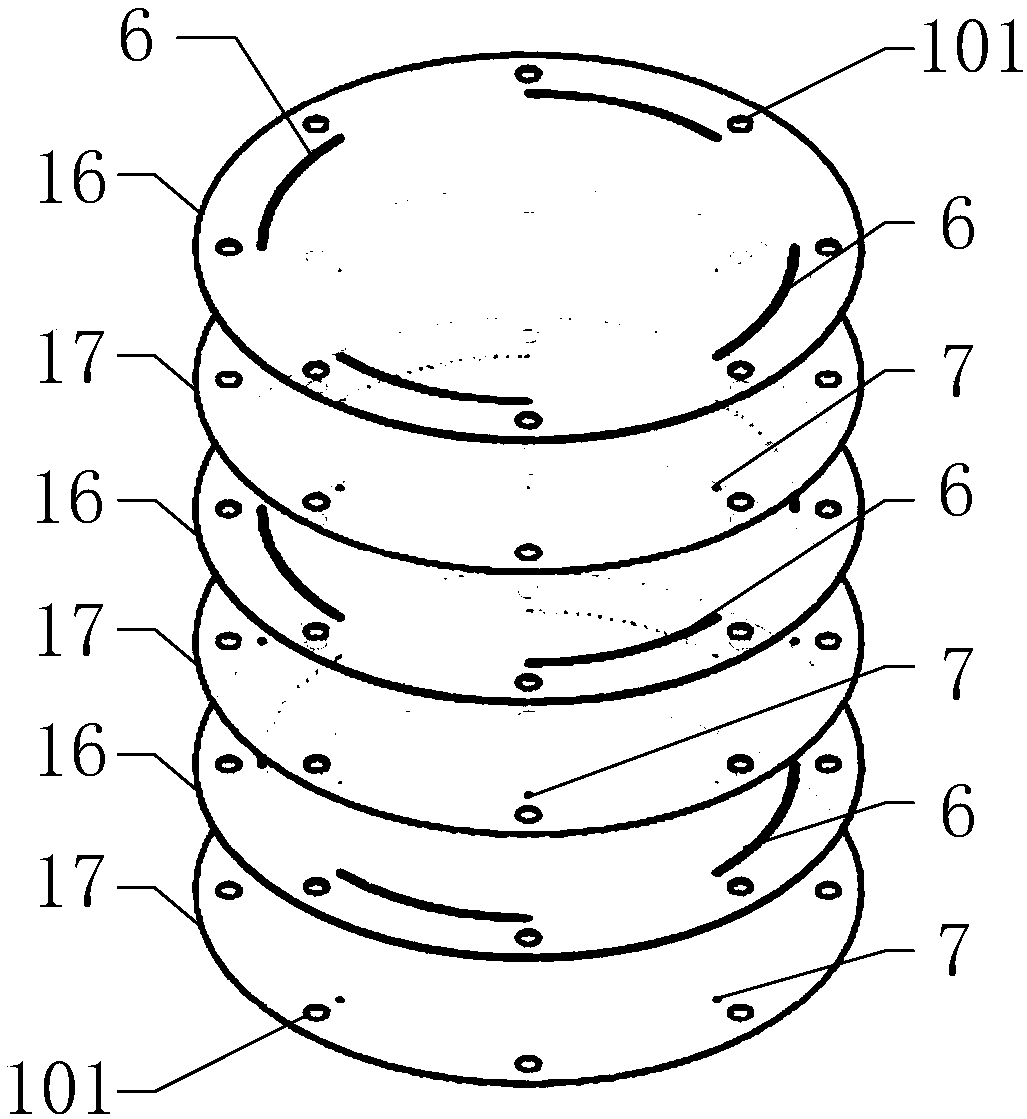

[0021] A three-dimensional helical structure cell sorting microfluidic chip according to the present invention comprises a sample inlet 1 for sending samples, at least two sample outlets set according to the size and quantity of cells to be sorted in the sample, One or more cell sorting channels for sorting cells of different sizes in a sample. In order to break through the limitation that only one microfluidic channel can be arranged in the existing planar microfluidic chip, which leads to low sorting efficiency, the present invention sets the cell sorting channel into a three-dimensional structure, so that when arranging multiple cell sorting In the case of flow channels, each flow channel is connected in parallel and does not interfere with each other. The cell sorting flow channel includes a three-dimensional helical micro-channel and a branch channel 8, the three-dimensional helical micro-channel communicates with the sample inlet 1 and extends in a spiral ladder to focus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com