A step robot workbench equipment

A robot workbench and workbench technology, applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problems of wasting manpower, material and financial resources, increasing product costs, unstacking, and handling labor, etc., to alleviate high-intensity operations, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

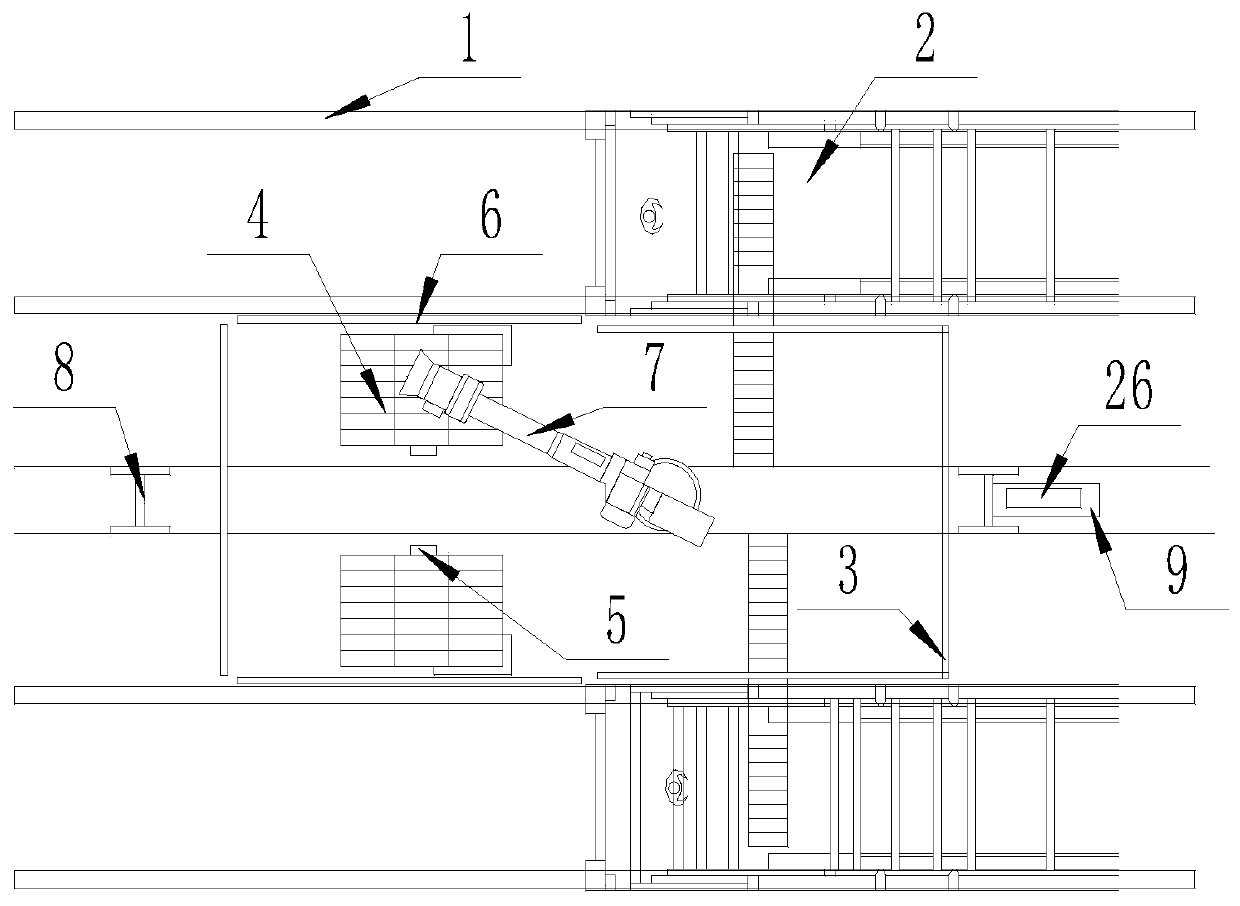

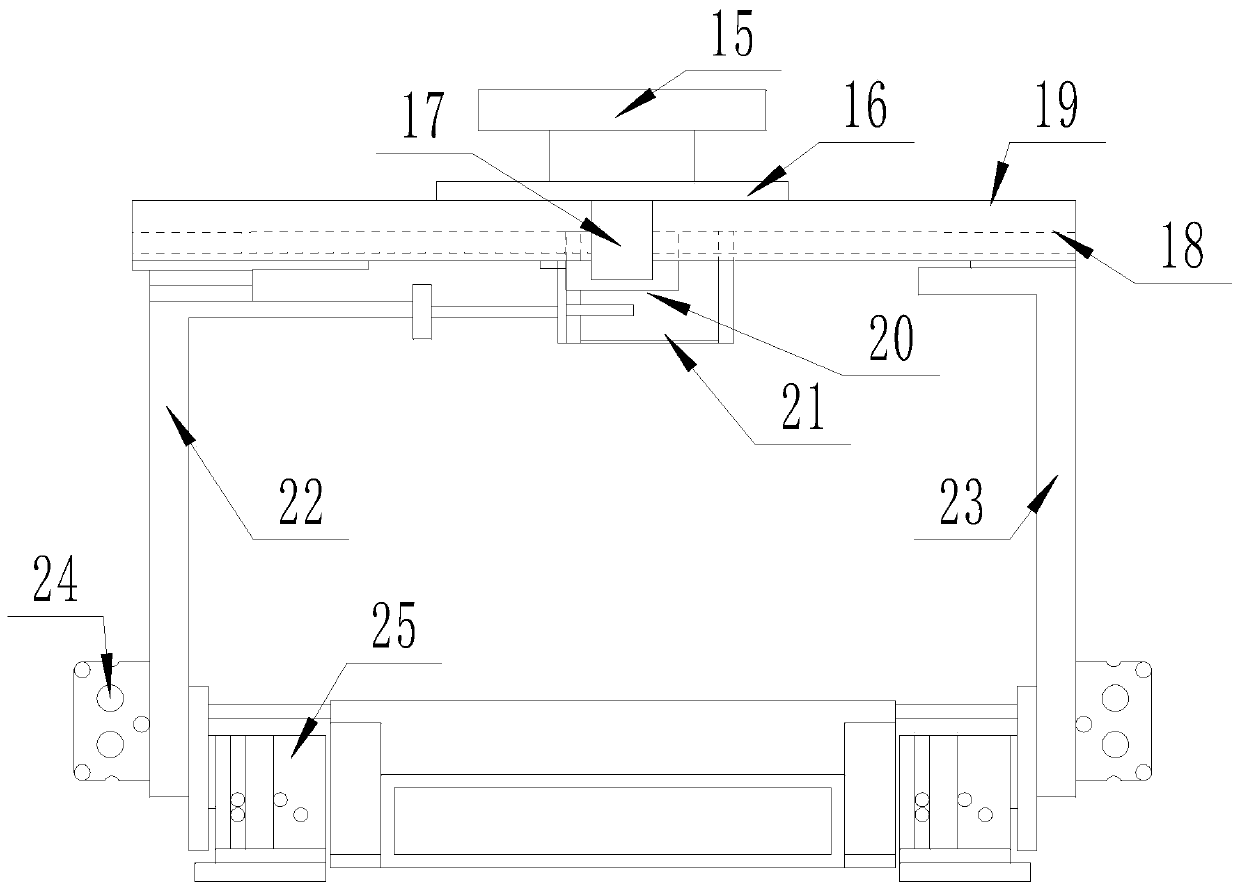

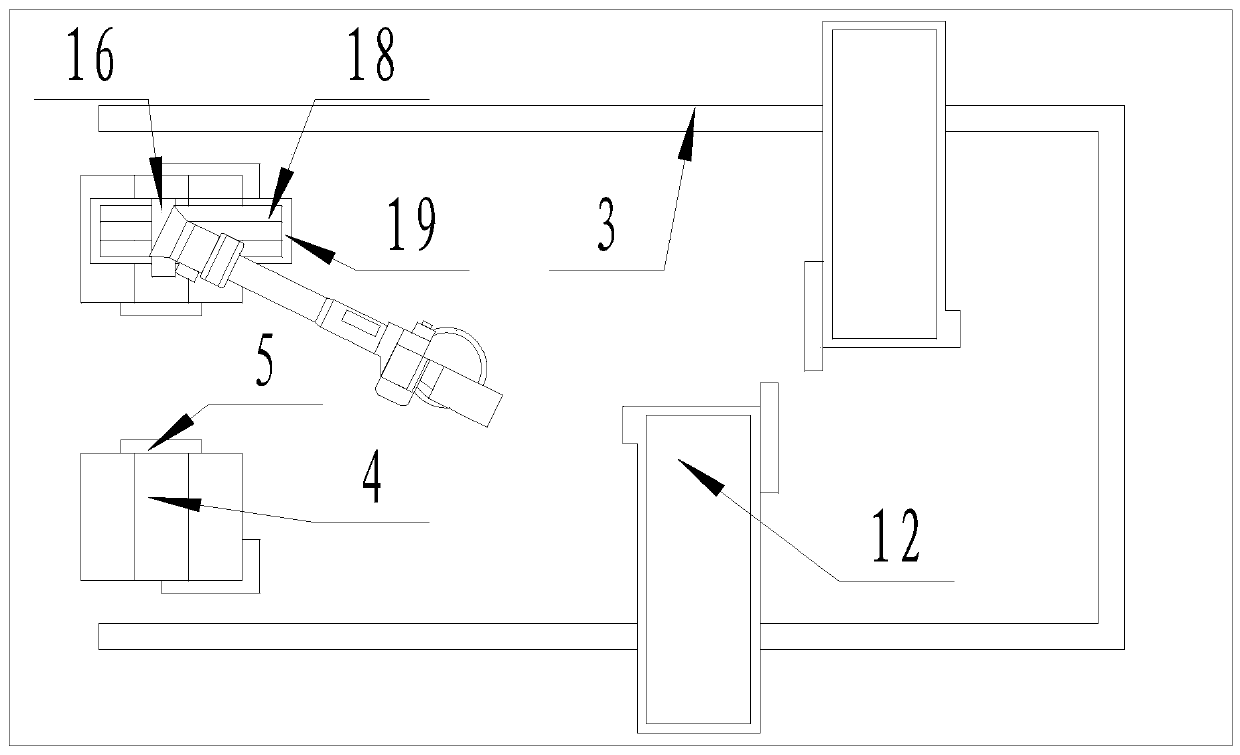

[0019] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 Shown, a kind of step robot workbench equipment comprises two mobile slide rails (1) and worktable mechanism, and described workbench mechanism is positioned between two mobile slide rails (1), and described two mobile slide rails ( 1) The lower head (2) of the escalator is provided inside, and the workbench mechanism consists of a guardrail (3) located between the two moving slide rails (1), and one end is fixedly installed between the two moving slide rails (1). The two step transport mechanisms on the ground and the other ends are respectively located in the two moving slide rails (1), the two step placement areas (4) are located on the guardrail (3) ground, and the two step placement areas are respectively arranged The step fork plate positioning device (5) at the bottom of the area (4), the safety light curtains (6) located on both sides of the two step pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com