Semiconductor process conveying system and method

A conveying system and semiconductor technology, applied in semiconductor/solid-state device manufacturing, conveyor objects, transportation and packaging, etc., can solve the problems of increased plant investment and cost, and achieve the effect of avoiding repeated operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples only illustrate possible embodiments of the present invention, which are not intended to limit the protection scope of the present invention, and are stated in advance.

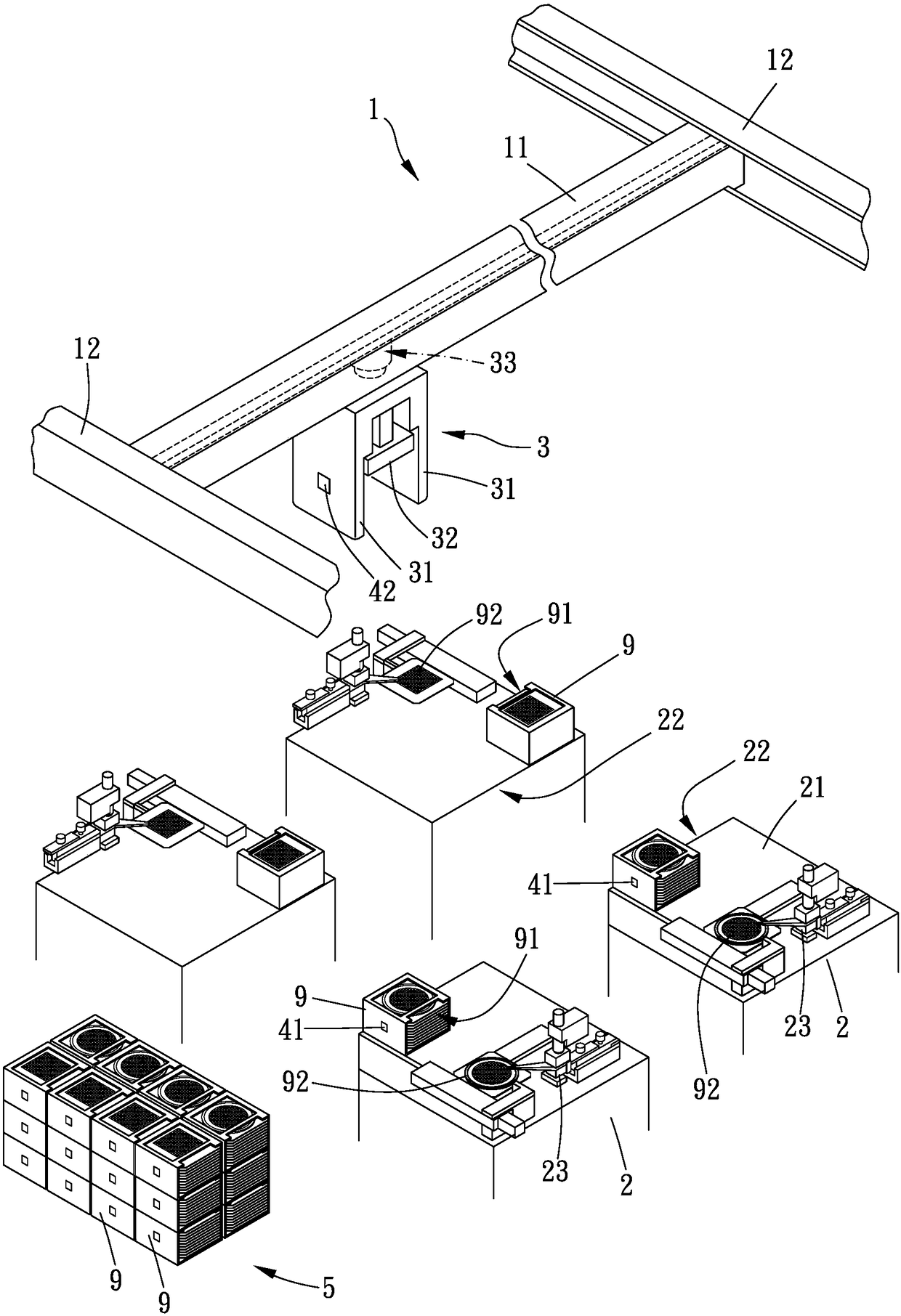

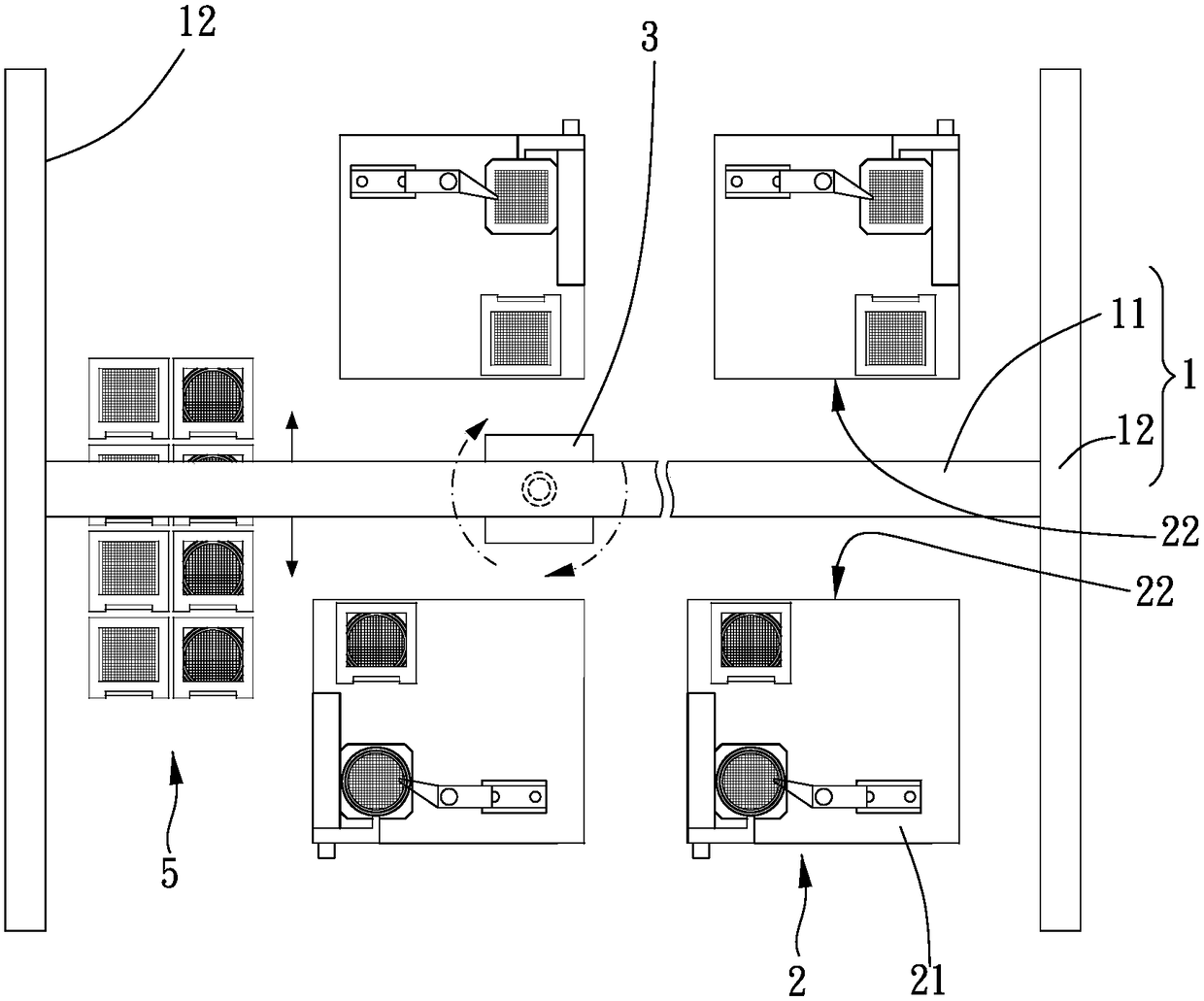

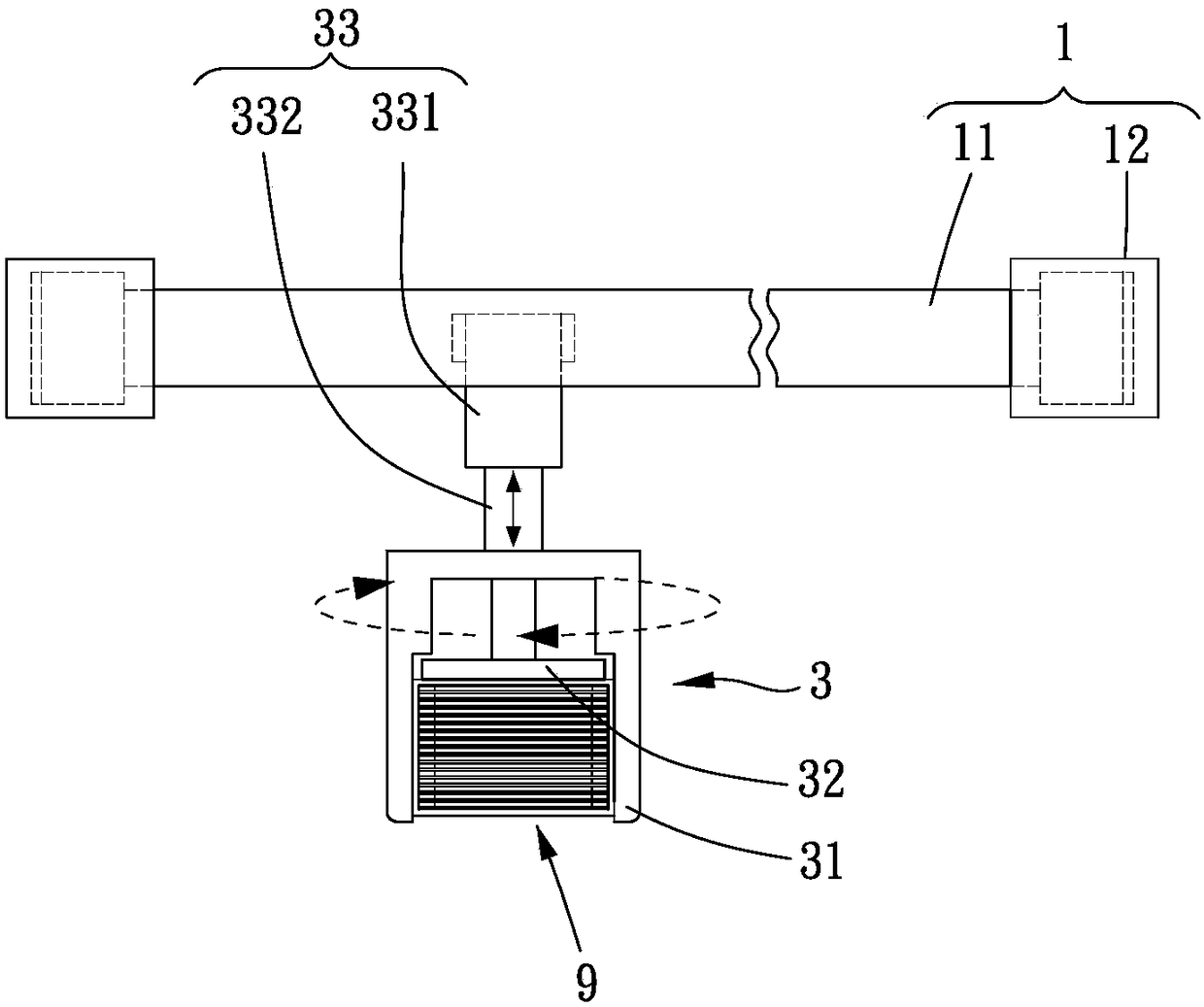

[0023] Please refer to Figures 1 to 3 , which shows a preferred embodiment of the present invention, the semiconductor process delivery system and method of the present invention includes a displacement mechanism 1 , a plurality of machines 2 and a pick-up mechanism 3 .

[0024] The displacement mechanism 1 includes a first track 11 extending along a first direction.

[0025] A plurality of machines 2 are respectively arranged on both sides of the first track 11, each machine 2 has a working platform 21, the working platform 21 is for placing at least one pod 9, and each pod 9 is for accommodating at least one wafer 92 , each working platform 21 has a feeding end 22 adjacent to and facing the first track 11 .

[0026] The taking mechanism 3 can be movably arranged on the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com