Observation room for anti-noise production site

An observation room and anti-noise technology, applied in special buildings, floors, small buildings, etc., can solve the problems of inability to solve the problem of solid-state sound transmission and the long-term impact of solid-state sound transmission, so as to solve noise hazards and reduce air pollution. effect of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

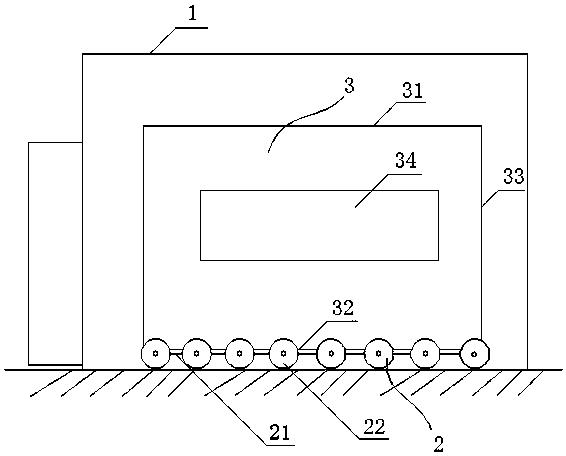

[0017] Such as figure 1 Shown, a kind of anti-noise production site observation room, an inner observation room 3 positioned on the vibration elimination unit 2 is set in the existing observation room 1, and the inner observation room 3 has no contact with the existing observation room 1; the vibration elimination The unit 2 includes a support frame 21 connected to the bottom of the inner observation chamber 3, and several inflatable vibration-absorbing pads 22 installed around the support frame 21 and in contact with the ground.

[0018] The inflatable vibration damping pad 22 is an air wheel. The use of inflatable wheels is to reduce the contact area between the shock absorbing pad and the ground, changing the surface contact to point contact, and the use of multiple inflatable wheels can meet the needs of supporting force.

[0019] The inner observation room 3 comprises a top plate 31, a bottom plate 32 and a side wall 33 made of sound-absorbing and insulating panels, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com