Flexible mud slag flushing gun head of triangular arrangement heat transfer tube

A technology of heat transfer tubes and triangles, which is applied in the field of cleaning heat transfer tubes of steam generators, and can solve problems such as steel strip pushing and deflecting actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

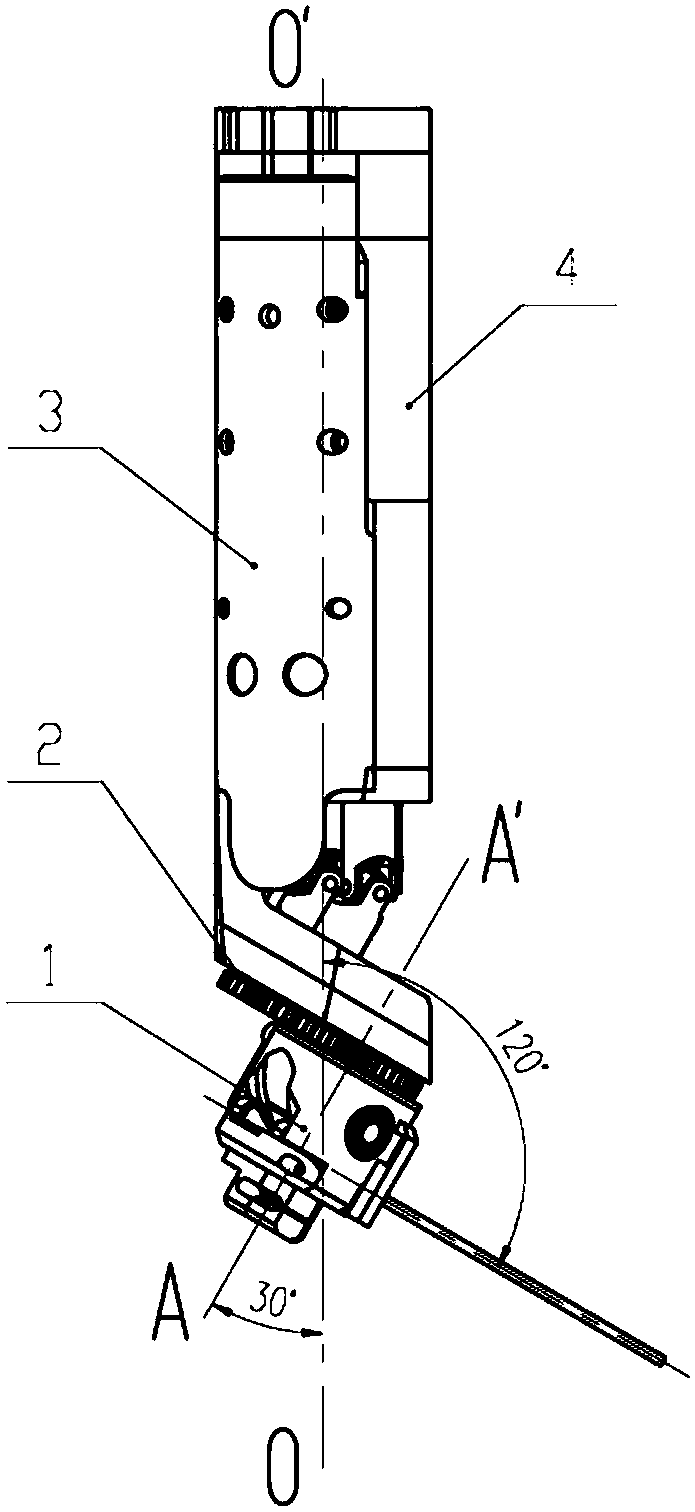

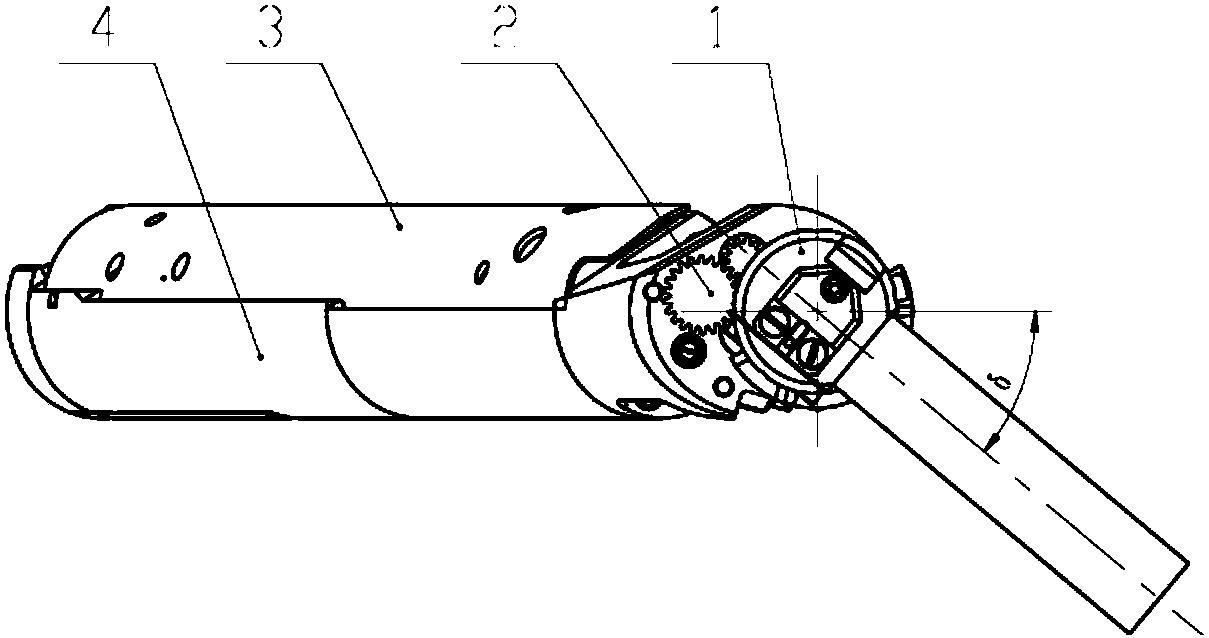

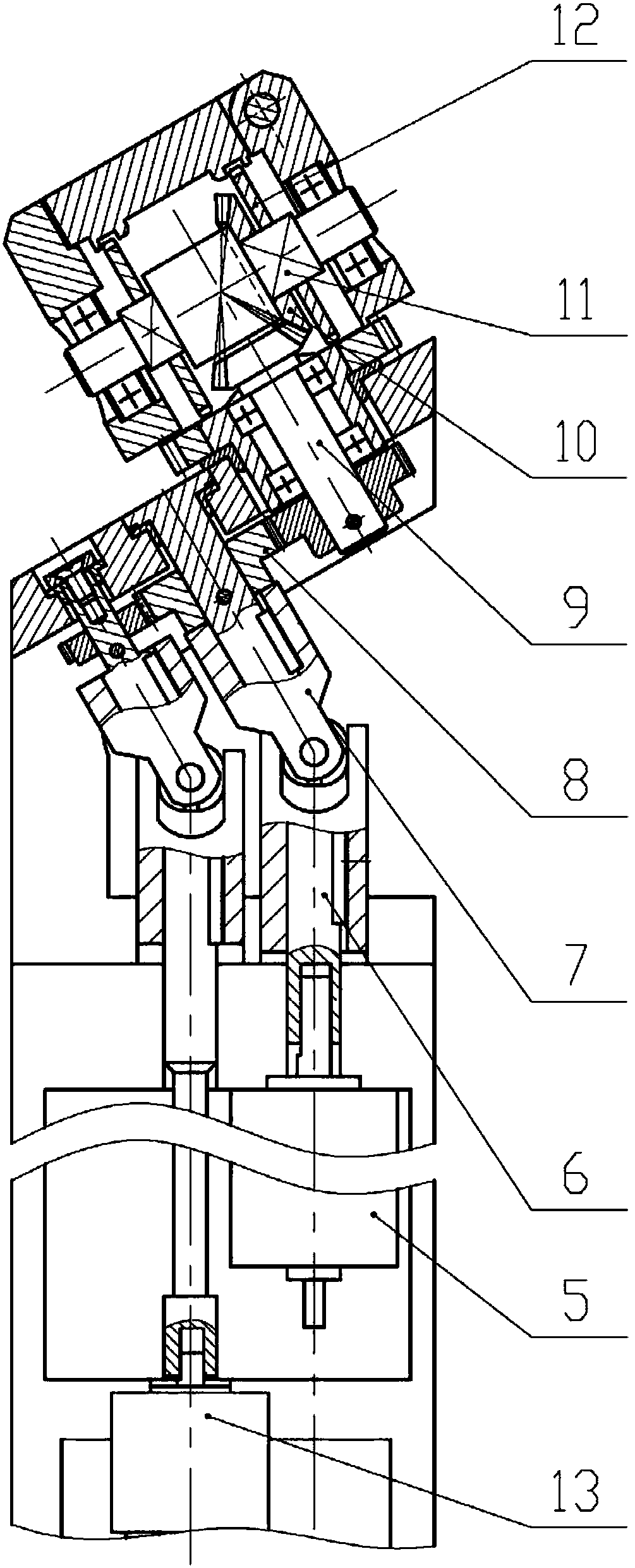

[0023] Such as Figure 1~6 As shown, a flexible sludge flushing gun head with heat transfer tubes in a triangular arrangement includes a push-pull gun head 1, a deflection gear train 2, a support cylinder 4, a push-pull motor 5 and a deflection motor 14, wherein the support cylinder 4 is Hollow D-shaped cylinder structure, and the steel strip cover plate 3 in the shape of an arc cover plate is fastened to form a cylindrical cavity. The end surface of the support cylinder 4 is an inclined surface, and the deflection gear train 2 and The push-pull gun head 1, and the central axis AA' of the push-pull gun head 1 and the axis OO' of the steel belt passage in the support cylinder 4 form an included angle of 30°. ′ Vertical, parallel to the heat transfer tubes; the push-pull motor 5 is fixedly installed on the support cylinder 4, and the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap