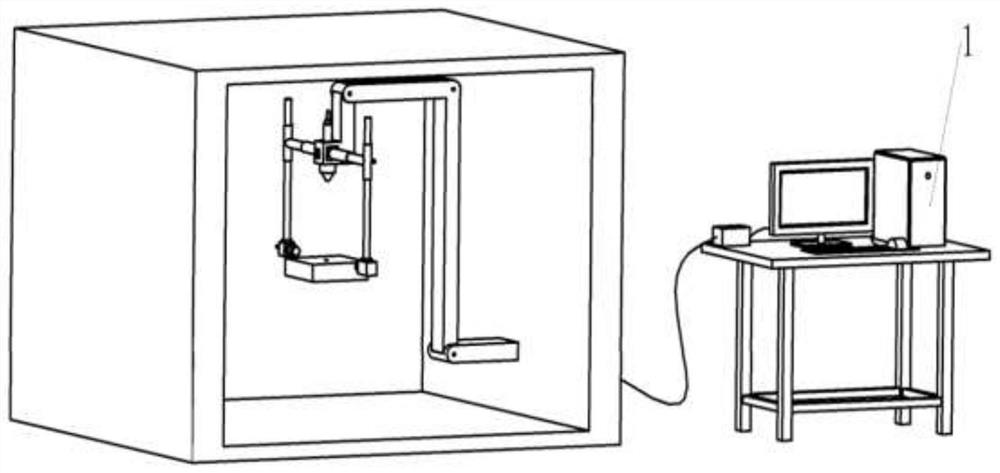

A synchronous monitoring system for laser additive manufacturing

A monitoring system and additive manufacturing technology, which is applied in the field of laser additive manufacturing synchronous monitoring system, can solve the problems that the molten pool morphology and melting process cannot be observed, the structure of the detection device is complicated, and it is difficult to detect accurately, etc., to achieve Good commercialization prospects, high scientific research value, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

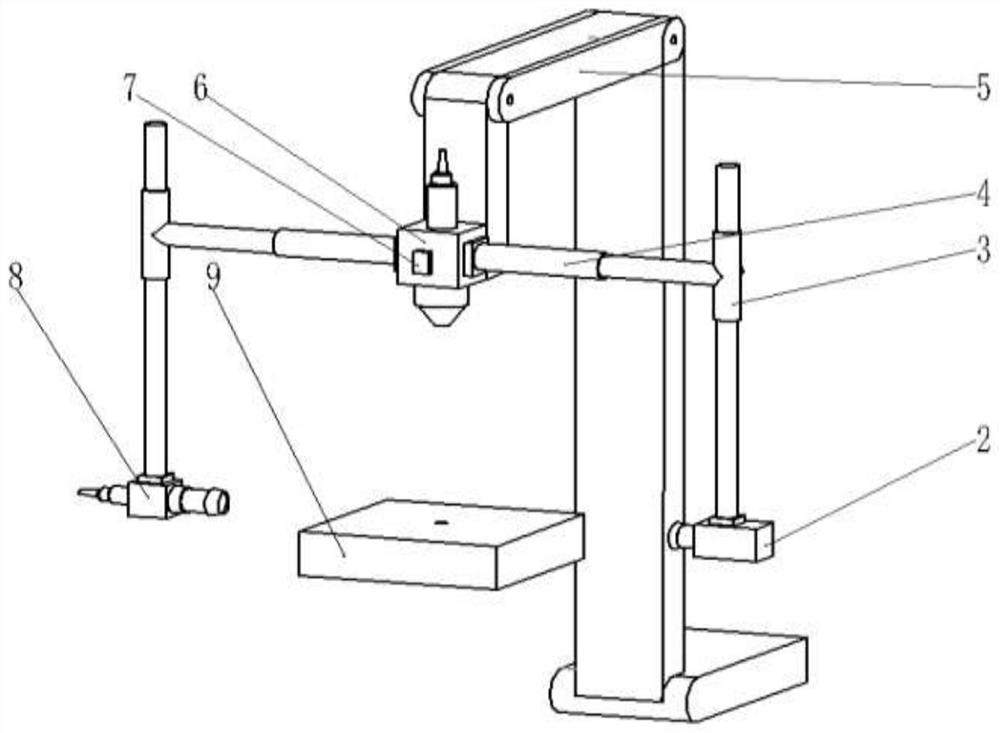

[0032] The technical parameter of the part that the present invention adopts is as follows:

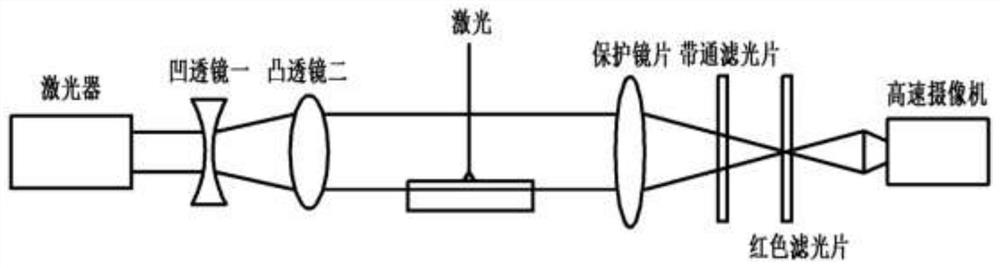

[0033] The technical parameters of the high-speed camera device are: CMOS sensor, the trigger mode is manual, continuous, synchronous, and pulse, the operating environment is WindowsXP / 7 / 10, the resolution is 800×600-1280×1024, and the camera frequency is 5000 frames / s-100000 frames / s, the exposure time is continuously adjustable within the range of 1μs-24ms, the zoom can reach 1x-160x, auto focus, accessory lens, image acquisition card, professional driver software, etc.;

[0034] The filter is a band-pass filter with a wavelength of 632.8nm and a half-bandwidth of 10nm; a red filter is optional for the colored filter;

[0035] The backlight source laser 8 is a helium-neon laser, the model is 25LHP928-230, the wavelength is 632.8nm, and the rated power is 35MW;

[0036] The power of the 3D printer laser transmitter 6 is 2000W-15000W;

[0037] The 3D printer model is LDM8060 powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com