Degradable PLA film material and preparation method thereof

A film material, PLA technology, applied in the field of degradable PLA film material and its preparation, can solve the problems of less than 20 minutes of service life and limit the application of degradable film, and achieve the effect of improving production efficiency and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

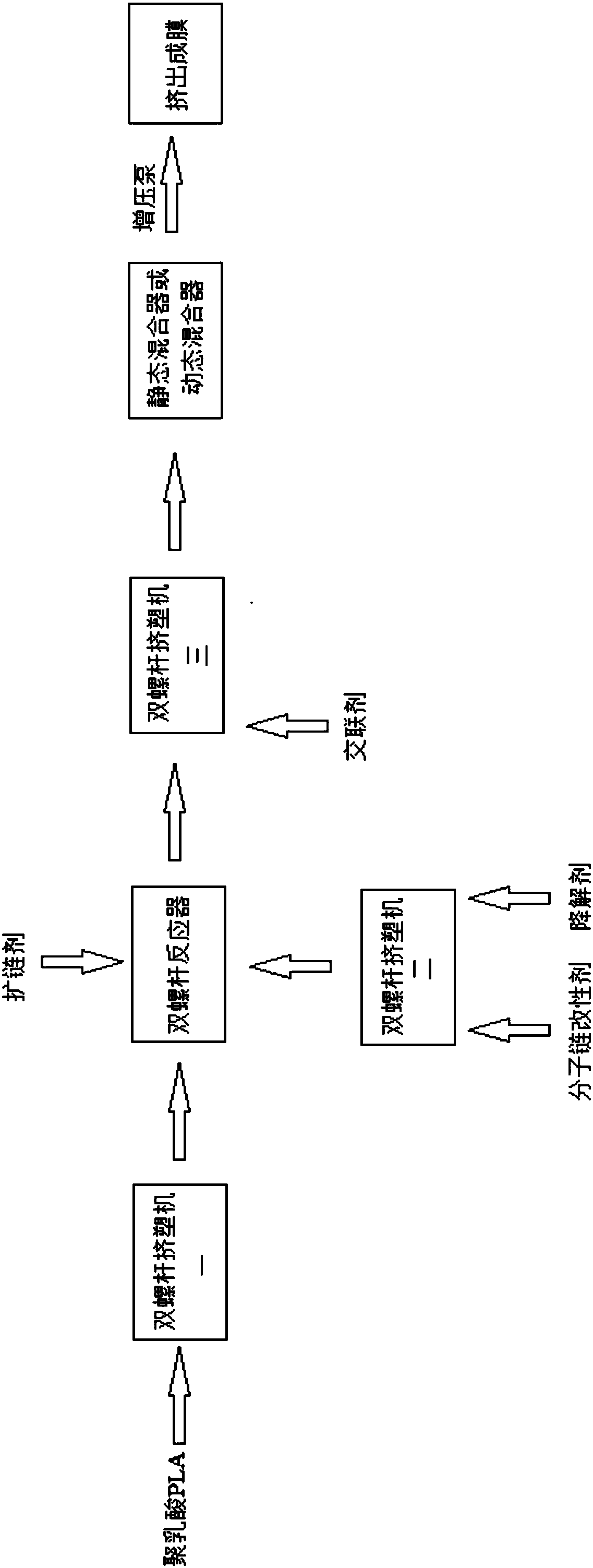

[0052] A preparation method of degradable PLA film material, comprising the following steps:

[0053] (1): Put 1-100 parts of polylactic acid into the screw extruder 1, the aspect ratio L / D of the twin-screw extruder 1: 36-48, the operating temperature is 120-200°C, and the screw speed is 50 -400rpm, shear melting to form a fluid hot melt.

[0054] (2): Put 1-50 parts of molecular chain modifier and 0-10 parts of degradation agent into the second screw extruder. The operating temperature of the second screw extruder is 130-260 ° C. Fluid hot melt 2, under the action of high-speed heat exchange and strong shearing of the threaded element, the molecular chain modifier is partially degraded by a degradation agent, and capped with groups such as hydroxyl groups; this step is to promote the degradation reaction Metal catalysts can be added, such as organotin / organozinc / organosilver catalysts.

[0055] (3): Pump hot melt 1 and hot melt 2 into the screw reactor, then add 0-10 parts...

Embodiment 1

[0072] A kind of preparation method of degradable PLA film material, its technique is as figure 1 shown, including the following steps:

[0073] (1): 100 parts of polylactic acid (this embodiment selects commercially available U.S. natureworks polylactic acid, M w 30K~50K) into the screw extruder 1, shearing and melting to form a fluid hot melt 1.

[0074] (2): Put 20 parts of molecular chain modifier (PHB in this example) and 5 parts of degradation agent (1,4-butanediol in this example) into the second screw extruder, at 180°C The shear melting reaction forms a fluid hot melt II.

[0075] (3): Hot melt one and hot melt two are pumped in the screw reactor, then add 10 parts of chain extender (this embodiment adopts the long-chain type polyurethane prepolymer of diisocyanate termination, and it is made of toluene 2, 4 diisocyanate TDI and polyols are polymerized), react at 200°C, and carry out disorderly rearrangement of molecular fragments;

[0076] (4): The reaction melt ...

Embodiment 2

[0086] Compared with Example 1, except that 10 parts of rubber was added in step (3) in this example (this example uses rubber terminated by hydroxyl groups at both ends), the rest are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com