Alkali liquid preparation box device

A liquid dosing tank and lye technology, applied in mixers with rotary stirring devices, transportation and packaging, mixer accessories, etc., can solve the problems of large demand and difficulty in ensuring liquid dosing, and achieve continuous configuration and constant temperature conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

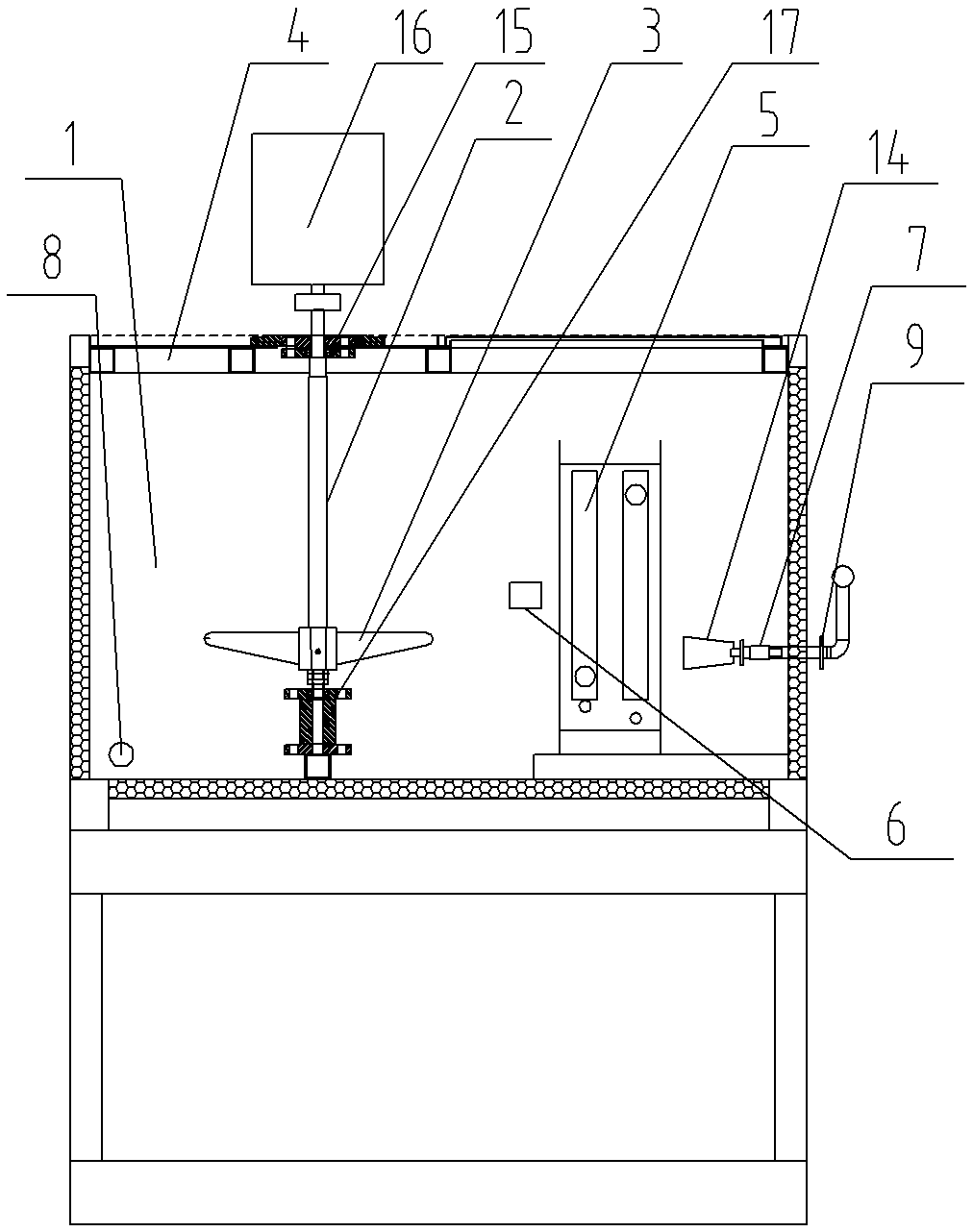

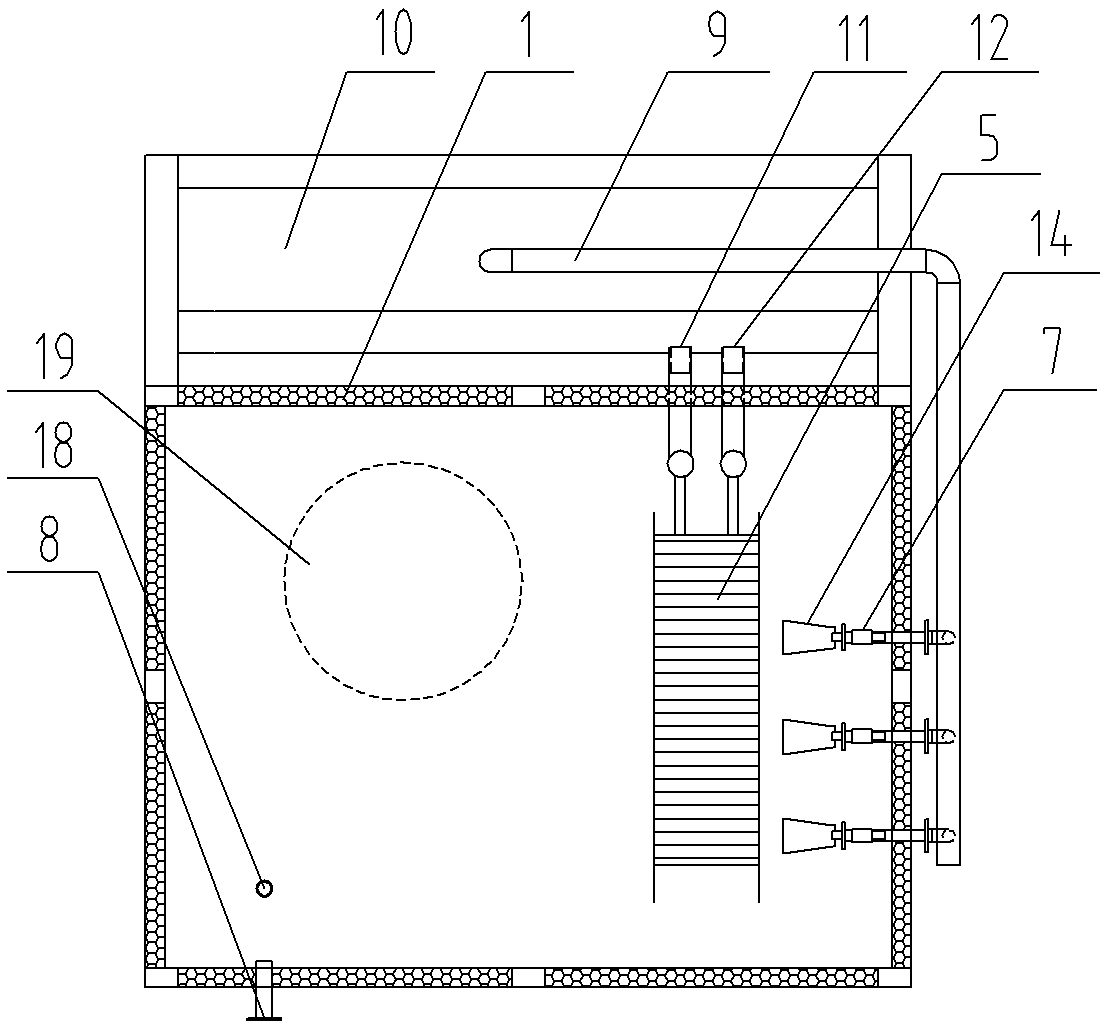

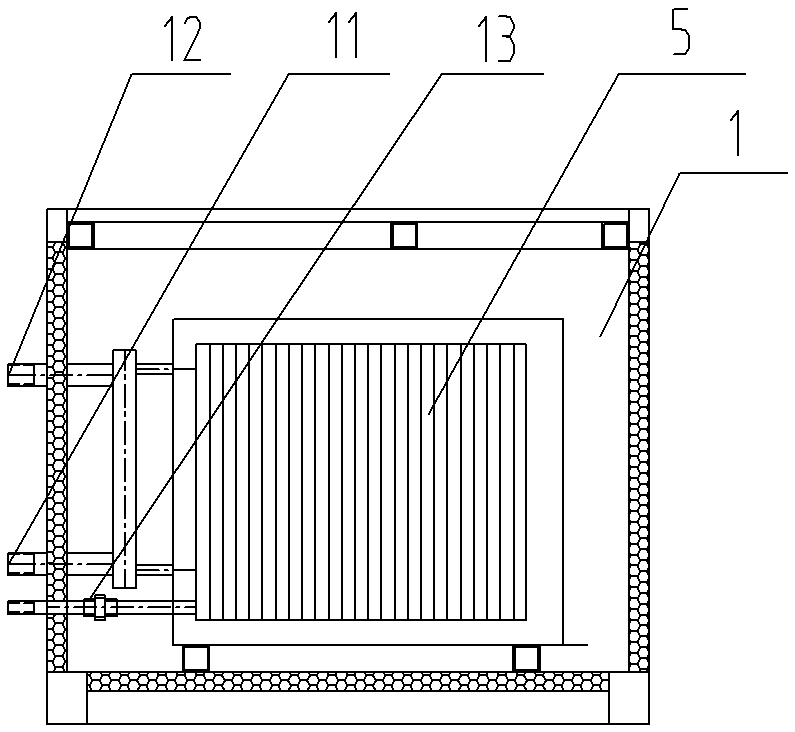

[0013] See figure 1 , figure 2 , image 3 As shown, a lye pressure distribution box device includes a box body 1, a stirring shaft 2 is installed in the box body 1, and a stirring paddle 3 is installed on the stirring shaft 2; on the side of the stirring shaft 2, the top of the box body 1 There is a feeding port 4, and on the other side of the stirring shaft 2, a heating tube 5 and a temperature sensor 6 are arranged in the box body 1; a liquid feeding pipe 7 and a liquid outlet 8 are installed on the side wall of the box body 1, and the liquid feeding pipe 7 runs through the tank 1 and is connected to the liquid storage tank 10 through the liquid delivery pipeline 9 . The heating pipe 5 is a steam heating pipe, and the steam heating pipe is provided with a hot steam inlet 11, a cold steam outlet 12 and a condensed water outlet 13; the liquid feeding pipe 7 includes three arranged side by side, and a horn is installed on the liquid feeding pipe 7 shaped outlet 14, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com