Bending machine

The technology of a bending machine and bending mechanism is applied in the field of bending machines to achieve the effects of reducing production costs, simplifying the structure, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

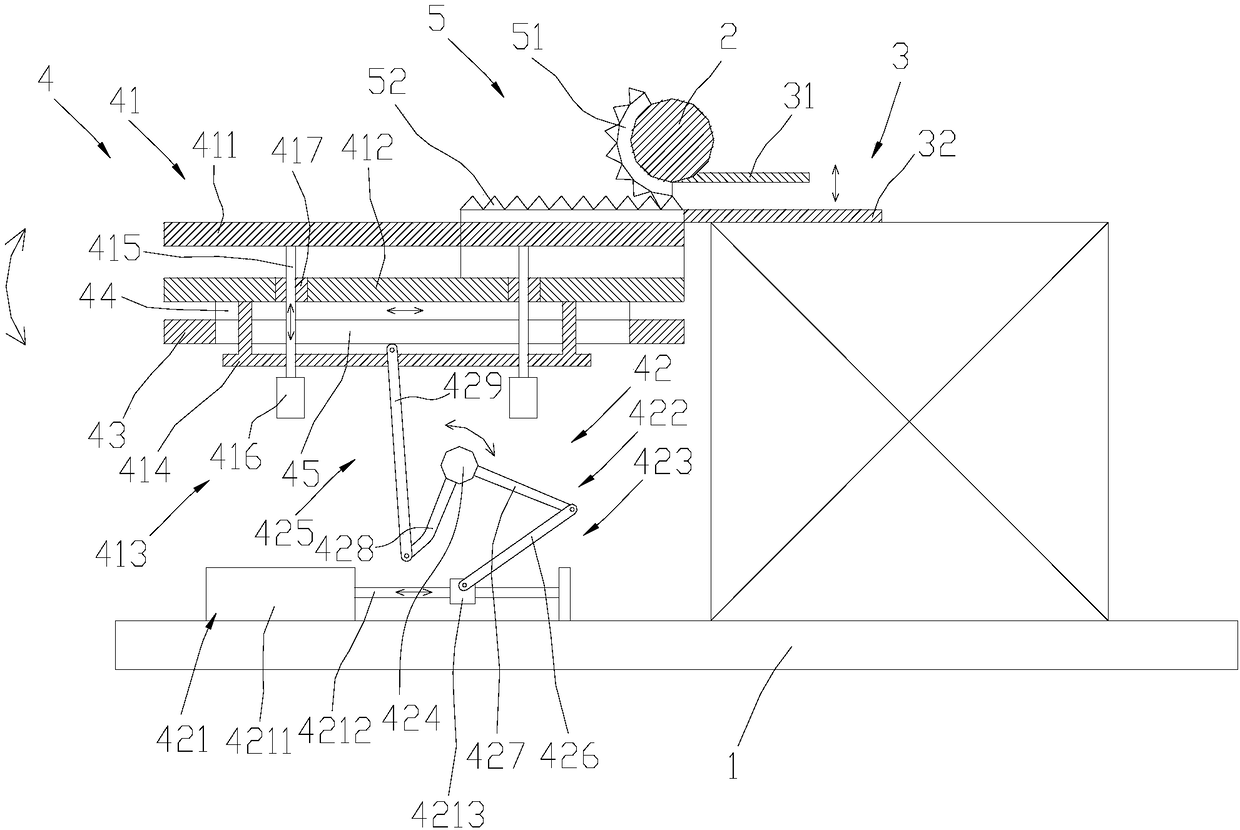

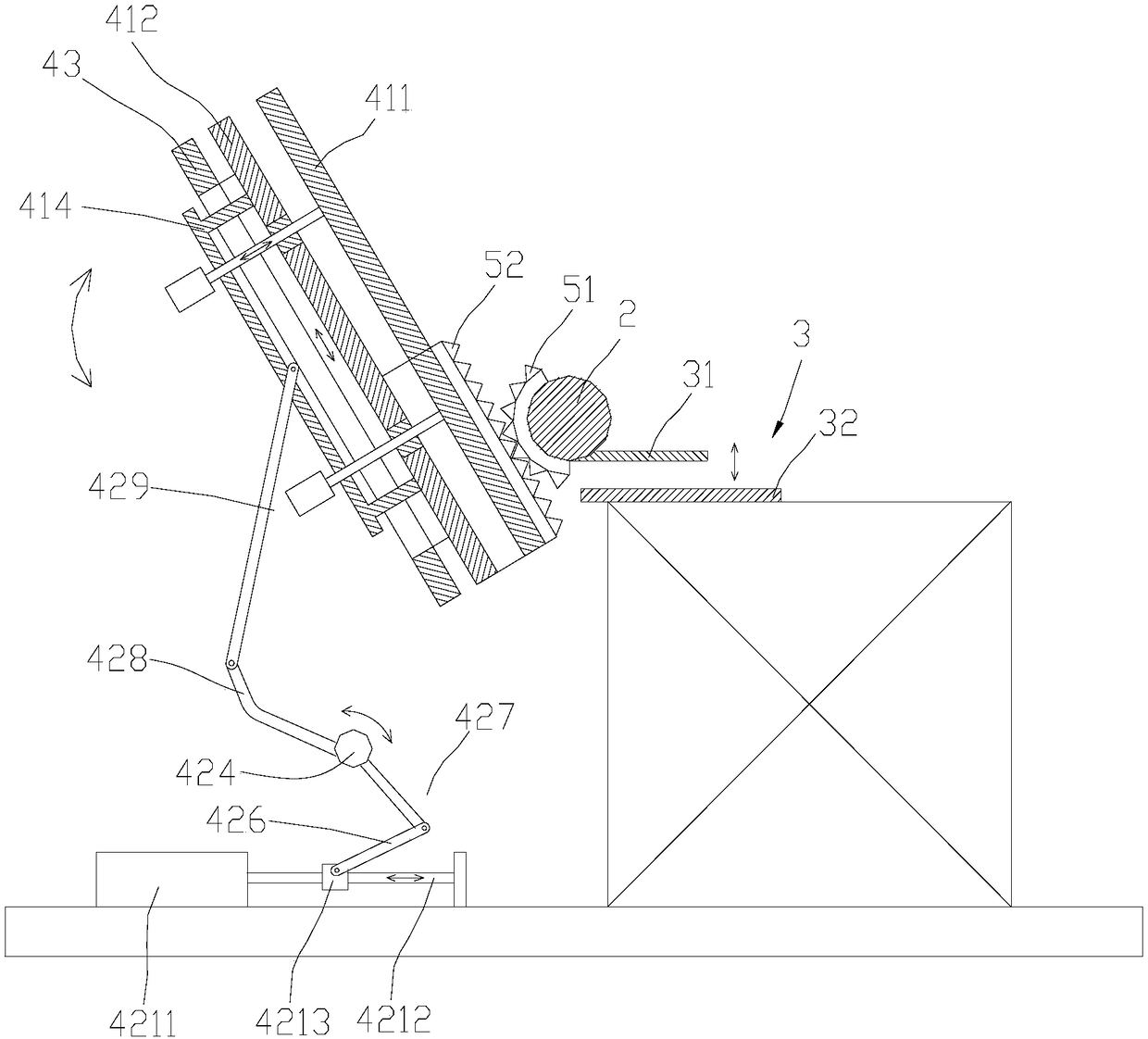

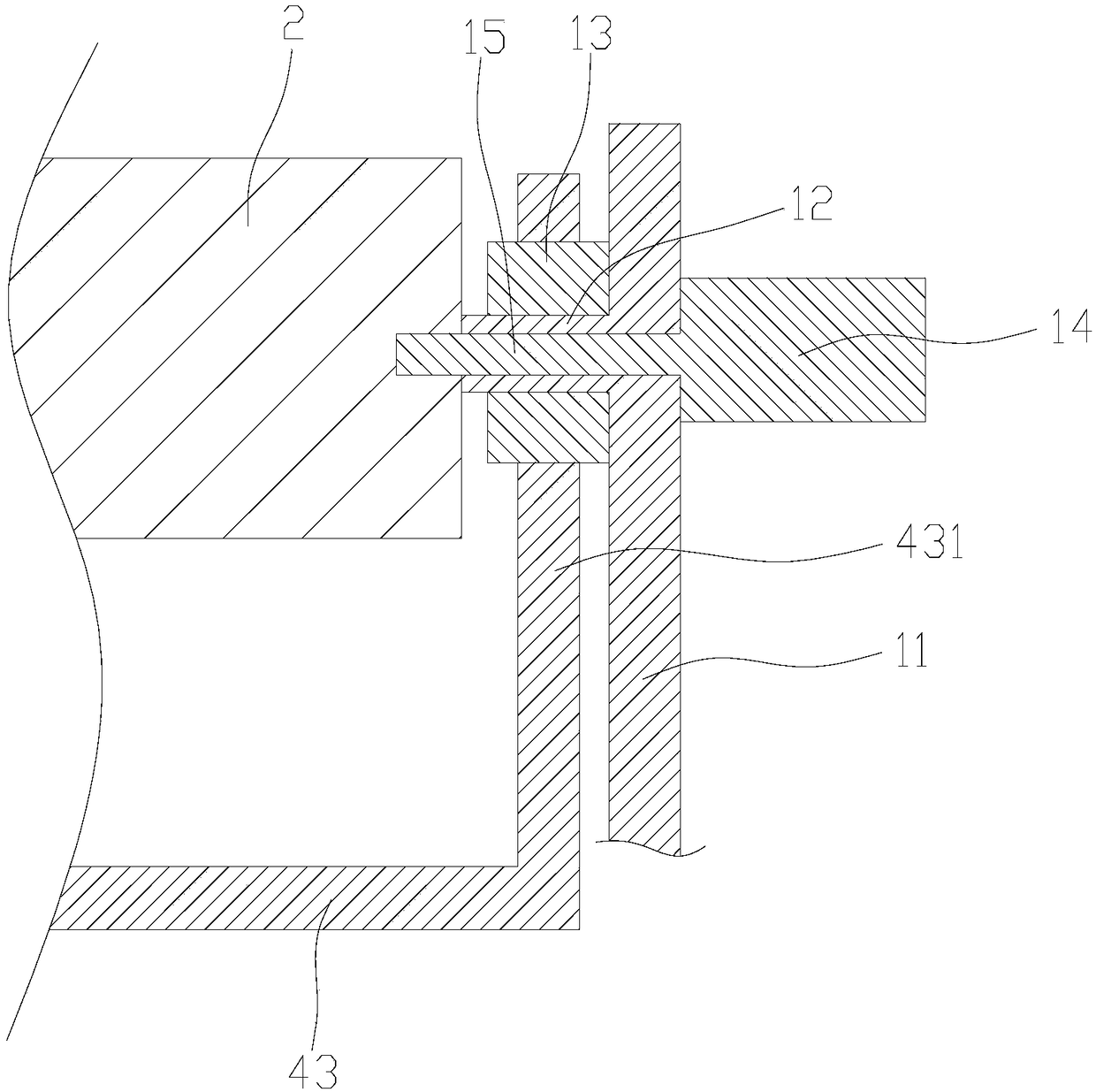

[0019] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

[0020] refer to figure 1 and figure 2 , a bending machine, comprising a base 1, the base 1 is provided with a turning roller 2, one side of the turning roller 2 is provided with a clamping mechanism 3, and the other side is provided with a bending mechanism 4, the folding The bending mechanism 4 can be bent around the turning roller 2, the bending mechanism 4 is provided with a follower plate 41, and a linkage mechanism 5 is arranged between the turning roller 2 and the follower plate 41, when the When the bending mechanism 4 bends around the rotating roller 2, the linkage mechanism 5 drives the follower plate 41 to move in linkage, so that the follower plate 41 moves with the workpiece.

[0021] Through the above-mentioned structural arrangement, when in use, the clamping mechanism clamps the workpiece, and the bending mechanism drives the workpiece...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap