Method of Axially Variable Stiffness of Ball Hinge Cooperating with I-shape Bushing and Laminated Spring and Ball Hinge

A laminated spring, I-shaped technology, applied in the direction of spring, spring/shock absorber, spring/shock absorber functional characteristics, etc., to reduce elastic vibration, broaden the design concept, and achieve the effect of later rigidity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

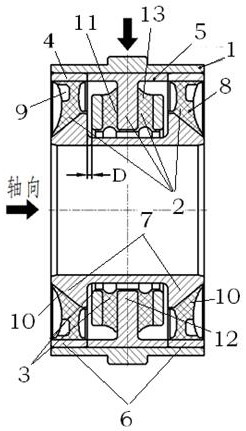

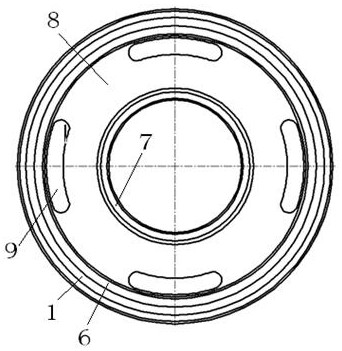

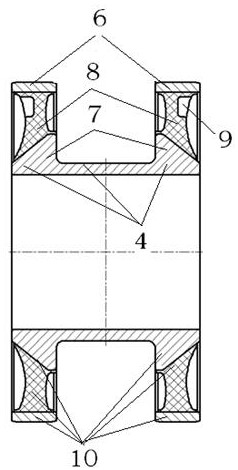

[0033] It can be seen from the accompanying drawings that the present invention relates to a spherical hinge with an axially variable rigidity of a ball hinge with an I-shaped bush and a laminated spring. It includes a casing sleeve 1, and a rubber metal The vulcanized body 2 realizes the nonlinear variable stiffness of the spherical joint through the deformation of the rubber metal vulcanized body 2; the rubber metal vulcanized body 2 is divided into two parts, one is an I-shaped rubber metal vulcanized body 4, and the other is a "T"-shaped Rubber metal vulcanized body 5; wherein, the "T" shaped rubber metal vulcanized body 5 is installed in the middle of the I-shaped rubber metal vulcanized body 4, so that the rubber metal vulcanized body of the whole ball dumpling is divided into three parts in the axial direction; the "T" shaped rubber metal vulcanized body After the metal vulcanized body 5 is combined with the I-shaped rubber metal vulcanized body 4, they are simultaneousl...

Embodiment 2

[0041] The implementation principle of the second embodiment is the same as that of the first embodiment, except that in order to further improve the effect of adjusting the axial stiffness, further adjustments are made to the multi-lobe multi-layer rubber-metal laminated spring. A ball hinge with a ball hinge variable stiffness method in which an I-shaped bush and a laminated spring are matched, including a shell sleeve, and a rubber metal vulcanized body is pressed into the shell sleeve, and the ball joint is realized through the deformation of the rubber metal vulcanized body The nonlinear variable stiffness; the rubber metal vulcanized body is divided into two parts, one is an I-shaped rubber metal vulcanized body, and the other is a "T" shaped rubber metal vulcanized body; wherein, the "T" shaped rubber metal vulcanized body is installed on In the middle of the I-shaped rubber metal vulcanized body, the rubber metal vulcanized body of the whole ball dumpling is divided int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com