Laminated spring for adjusting axial nonlinear stiffness of traction ball hinge and adjustment method

A technology of laminated springs and traction balls, applied in the direction of springs, springs, springs/shock absorbers made of plastic materials, to achieve flexible late stiffness requirements, achieve high nonlinearity, and reduce elastic vibration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

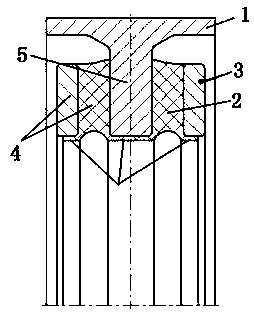

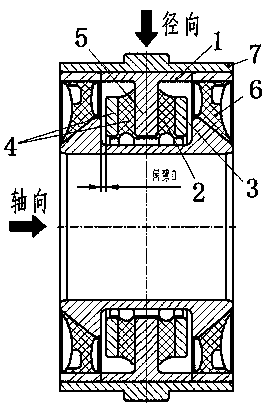

[0032] It can be seen from the accompanying drawings that the present invention relates to a rubber-metal laminated spring for adjusting the axial nonlinear stiffness of a traction ball hinge, which includes a metal jacket 1 in which a rubber elastic body 2 and a metal partition 3 are compounded. The rubber-metal laminated spring 4 is formed, and the rubber-metal laminated spring 4 is arranged axially, and the axial nonlinear variable stiffness of the ball joint is realized through the deformation of the axially arranged rubber-metal laminated spring 4 .

[0033] Further, the rubber-metal laminated spring 4 is a "T"-shaped rubber-metal laminated spring, the metal jacket 1 of the "T"-shaped rubber-metal laminated spring is a "T"-shaped metal skeleton, and the rubber-metal laminated spring 4 They are distributed symmetrically on both sides of the radial banner 5 of the "T"-shaped metal skeleton.

[0034] Further, the rubber-metal laminated spring 4 is an axial laminated spring f...

Embodiment 2

[0041] The implementation principle of the second embodiment is the same as that of the first embodiment, except that in order to further improve the effect of small stiffness adjustment, further processing is carried out on the small stiffness adjustment rubber parts. A laminated spring for adjusting the axial nonlinear stiffness of a traction ball hinge, including a metal jacket, in which there is a rubber-metal laminated spring composed of a rubber elastic body and a metal compound, and the rubber-metal laminated spring is axially arranged The axial non-linear variable stiffness of the ball joint is realized through the deformation of the axially arranged rubber-metal laminated spring.

[0042] Further, the rubber-metal laminated spring is a "T"-shaped rubber-metal laminated spring, the jacket of the "T"-shaped rubber-metal laminated spring is a "T"-shaped metal skeleton, and the laminated springs are distributed in the "T" shape. The two sides of the radial banner of the m...

Embodiment 3

[0049] The implementation principle of the third embodiment is the same as that of the first embodiment, except that in order to further improve the performance of the entire variable stiffness, the variable stiffness is adjusted by simultaneously compressing the radial direction and the axial direction. A laminated spring for adjusting the axial nonlinear stiffness of a traction ball hinge, including a metal jacket, in which there is a rubber-metal laminated spring composed of a rubber elastic body and a metal compound, and the rubber-metal laminated spring is axially arranged The axial non-linear variable stiffness of the ball joint is realized through the deformation of the axially arranged rubber-metal laminated spring.

[0050] Further, the rubber-metal laminated spring is a "T"-shaped rubber-metal laminated spring, the jacket of the "T"-shaped rubber-metal laminated spring is a "T"-shaped metal skeleton, and the laminated springs are distributed in the "T" shape. The two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com