A method for adjusting nonlinear variable stiffness of rubber-metal composite spherical hinge

A rubber-metal composite, rubber-metal technology, applied in the functional characteristics of springs/shock absorbers, springs made of plastic materials, springs/shock absorbers, etc., to broaden the design concept, flexible later stiffness requirements, and achieve a high degree of nonlinearity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

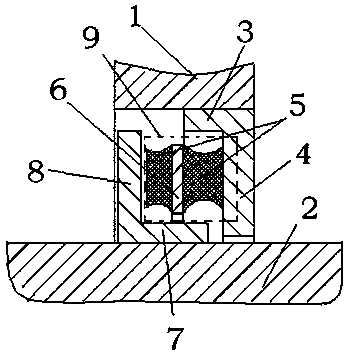

[0031] It can be seen from the accompanying drawings that the present invention relates to a method for nonlinear variable stiffness of a rubber-metal composite ball hinge, which adjusts the non-linear rigidity of the rubber-metal composite ball hinge by adjusting the positional relationship between the metal parts and the rubber parts of the rubber-metal composite ball hinge. Linear variable stiffness, which is characterized by adjusting the positional relationship between the metal parts and the rubber parts of the rubber-metal composite ball hinge. Adjusting the nonlinear variable stiffness of the rubber-metal composite ball hinge is by adjusting the axial variable Stiffness, so that the axial stiffness of the entire rubber-metal composite ball joint changes nonlinearly, and the nonlinear variable stiffness of the rubber-metal composite ball joint is adjusted through the nonlinear change of the axial stiffness of the rubber-metal composite ball joint.

[0032] The adjustment...

Embodiment 2

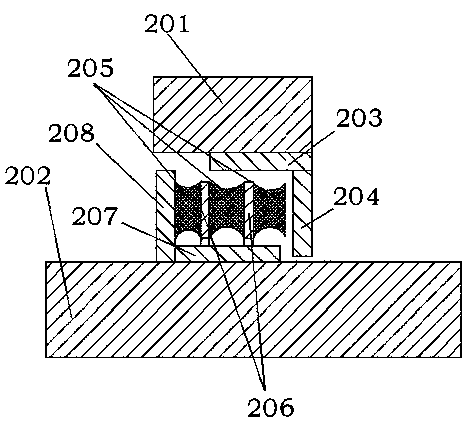

[0040] The implementation principle of the second embodiment is the same as that of the first embodiment, but the adjustment method is different. It is a non-linear variable stiffness method for rubber-metal composite ball hinges, which adjusts the nonlinear variable stiffness of rubber-metal composite ball hinges by adjusting the positional relationship between the metal parts and the rubber parts of rubber-metal composite ball hinges. The positional relationship between the metal parts and the rubber parts of the rubber-metal composite ball hinge adjusts the nonlinear variable stiffness of the rubber-metal composite ball hinge. By adjusting the axial variable stiffness of the rubber-metal composite ball hinge, the entire rubber-metal composite ball hinge The axial stiffness of the hinge varies nonlinearly, and the nonlinear variable stiffness of the rubber-metal composite spherical hinge is adjusted through the nonlinear variation of the axial stiffness of the rubber-metal co...

Embodiment 3

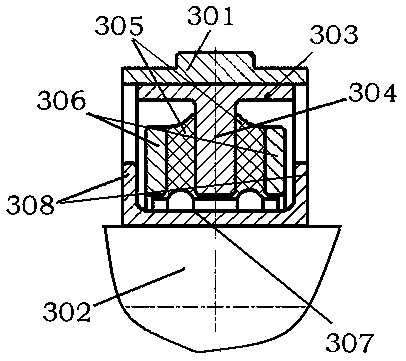

[0050] The implementation principle of Embodiment 3 is the same as that of Embodiment 1, except that the adjustment method is slightly different. It is a method of nonlinear variable stiffness of rubber-metal composite ball hinges. By adjusting the metal parts and rubber of rubber-metal composite ball hinges Adjust the nonlinear variable stiffness of the rubber-metal composite ball joint by adjusting the positional relationship of the rubber-metal composite ball joint. By adjusting the axial variable stiffness of the rubber-metal composite ball joint, the axial stiffness of the entire rubber-metal composite ball joint changes nonlinearly, and the rubber-metal composite ball joint is adjusted through the nonlinear change of the axial stiffness of the rubber-metal composite ball joint. Nonlinear variable stiffness of a spherical joint.

[0051] The adjustment of the axial variable stiffness of the rubber-metal composite ball hinge is to install an axial variable stiffness adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com