Assembly structure and air conditioner

An assembly structure and assembly technology, applied in space heating and ventilation details, household heating, lighting and heating equipment, etc., can solve problems affecting the overall appearance, unfavorable assembly operation, low assembly efficiency, etc., and achieve a sense of user experience Good, good assembly effect, easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

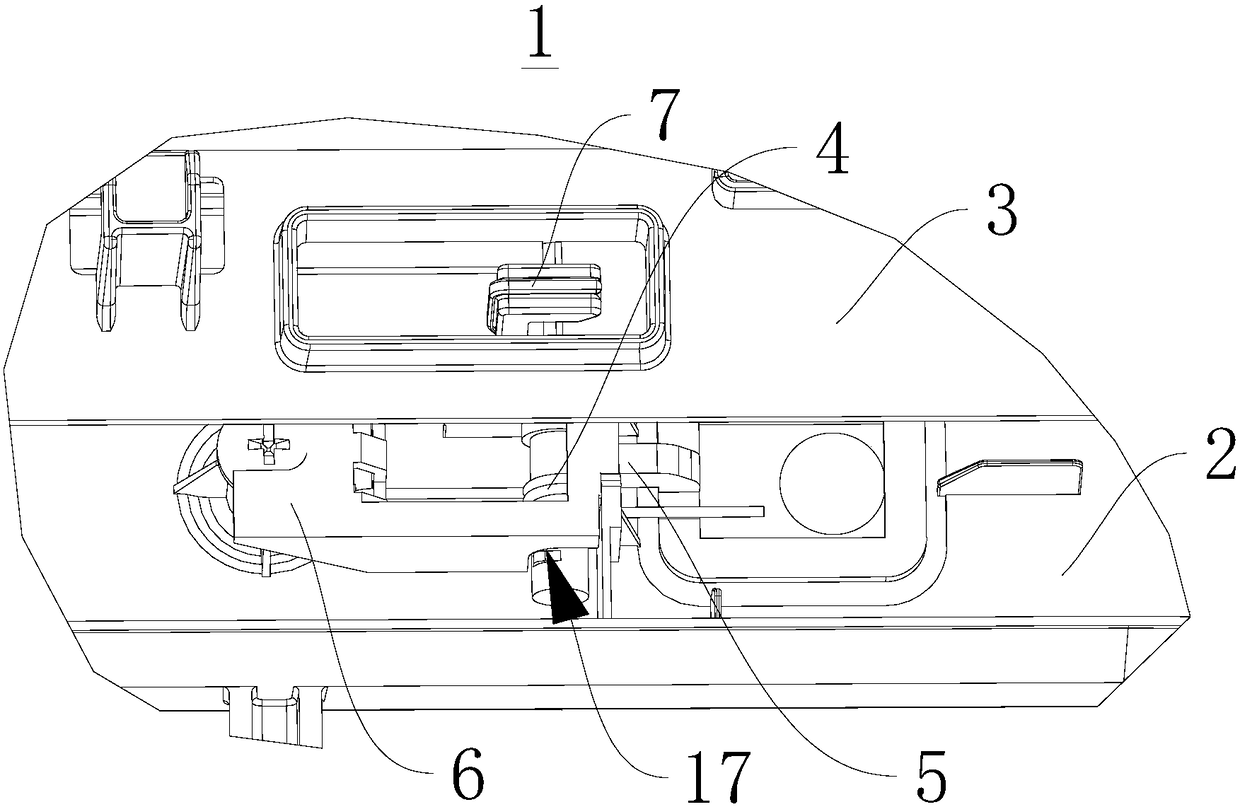

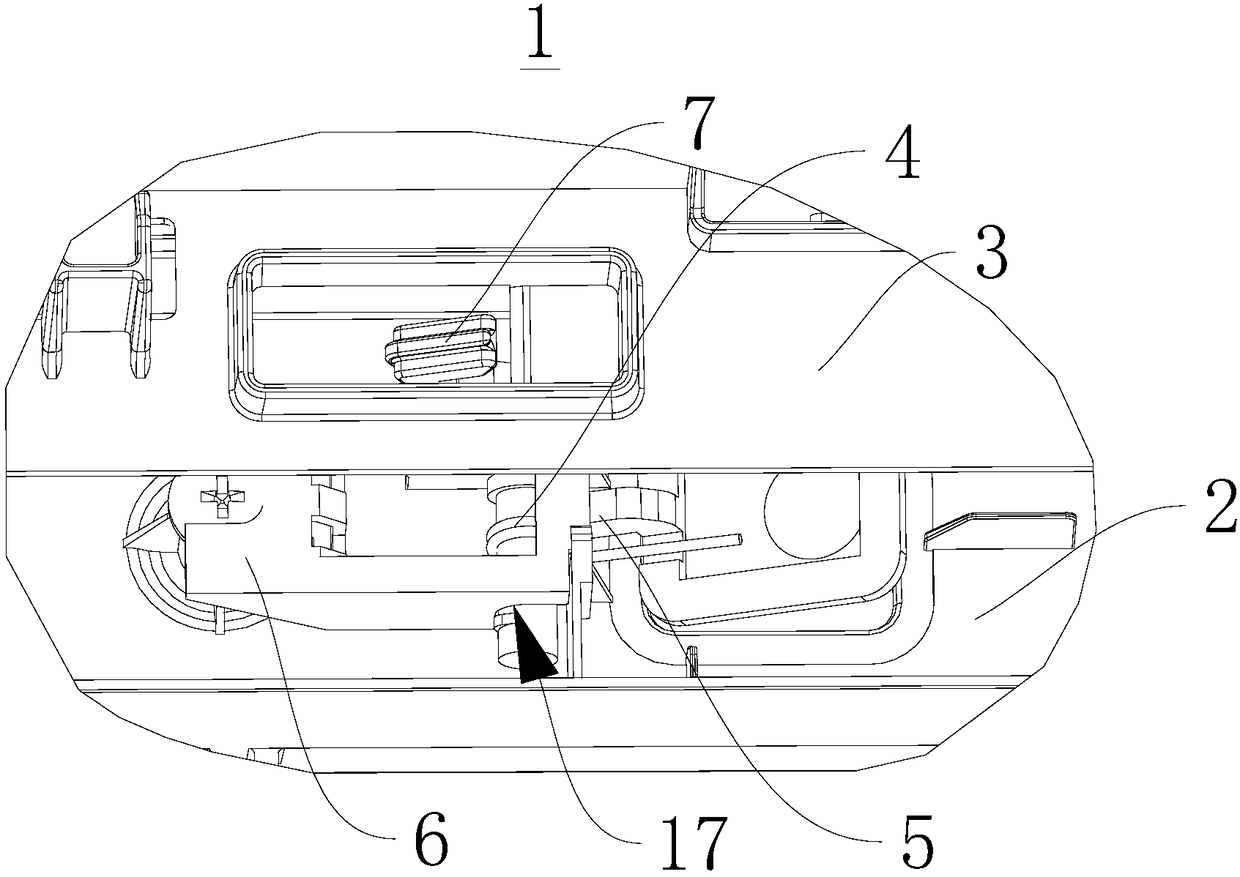

[0034] Please refer to figure 1 with figure 2 , the embodiment of the present invention provides an assembly structure 1 for connecting and assembling related parts and fixing relative positions. The utility model has the advantages of simple structure, convenient disassembly and assembly, stable and reliable after assembly, not easy to loosen, good assembly effect, does not affect the overall appearance, and has strong practicability.

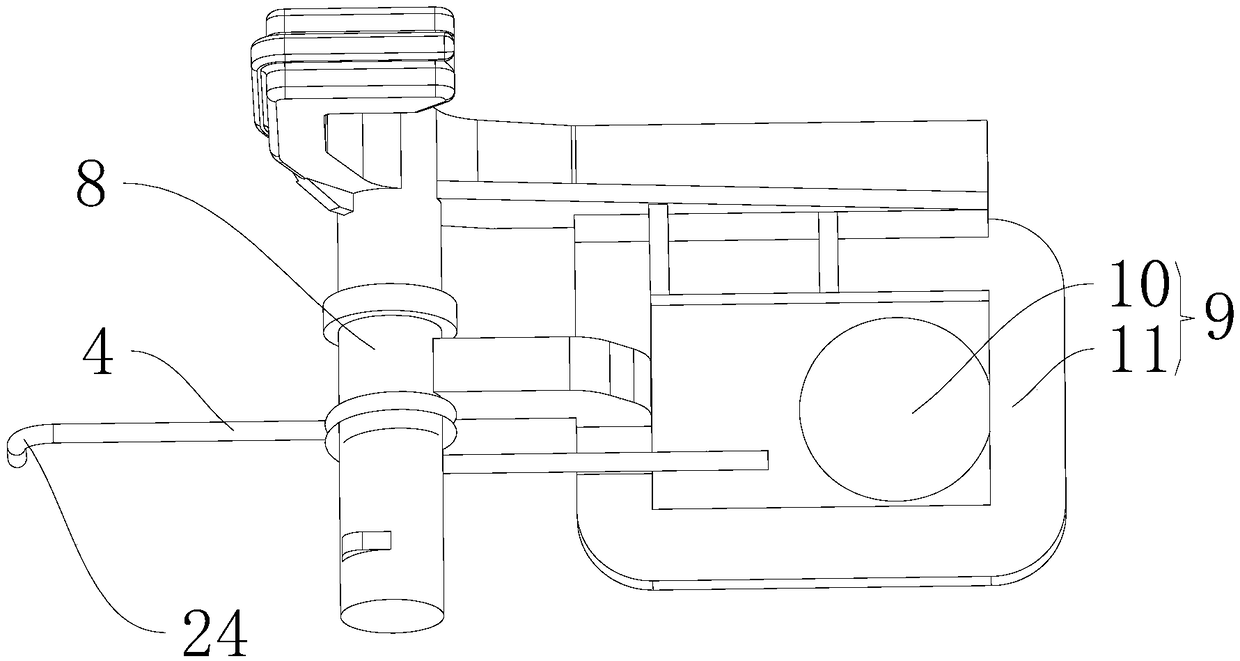

[0035] The assembly structure 1 includes a first assembly body 2 , a second assembly body 3 , an elastic member 4 , a rotating member 5 and a fixing seat 6 . The fixing seat 6 is fixedly installed on the first assembly body 2 and combined with the first assembly body 2 to form an assembly cavity 17 for accommodating the rotating member 5 and preventing the rotating member 5 from falling off. The rotating member 5 is installed in the assembly cavity 17 and can rotate relative to the first assembly body 2 . The elastic member 4 is sheathed o...

no. 2 example

[0048] An embodiment of the present invention provides an air conditioner (not shown), including a panel (not shown), a grille (not shown) and an assembly structure 1 . Wherein, the basic structure, principle and technical effect of the assembly structure 1 are the same as those of the first embodiment. For the sake of brief description, for parts not mentioned in this embodiment, reference may be made to the corresponding content in the first embodiment.

[0049] In this embodiment, the first assembly body 2 is arranged on the panel, the second assembly body 3 is arranged on the grid, and the grid is detachably connected to the panel through the assembly structure 1, which is convenient and practical.

[0050] The beneficial effect of the air conditioner described in the embodiment of the present invention is the same as that of the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com