A Pressure Balanced Expansion Joint Based on End Face Sliding Seal Compensation Technology

A sliding seal and expansion joint technology, which is applied to expansion compensation devices, pipe components, mechanical equipment, etc. for pipelines, can solve the problems of uneconomical, harsh end flange force, etc., to improve the force and increase the lateral Displacement compensation capability, effect of thinning design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

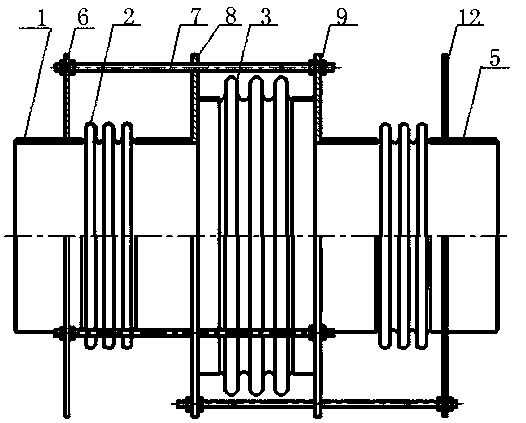

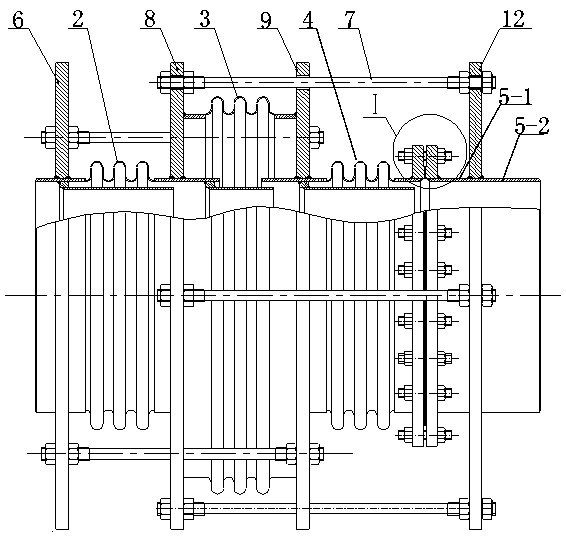

[0022] Such as figure 1 The shown pressure balance expansion joint adopts end face sliding seal compensation technology, its main structure is consistent with the straight pipe pressure balance type expansion joint in GB / T12777, the end face sliding seal compensation structure is added, and the tie rod and end Plate I and end plate II are connected according to the diagram. Such as figure 2 shown in figure 1 Based on the improvement, the end plate II12 and the outlet pipe 5 form an external rigid connection structure through the tie rod 7 and the intermediate pipe assembly I8. A new end flange B11 is added to the outlet pipe 5 as a sliding flange, and the end flange A10, sliding flanges, flange bolts 14, flange gaskets 18, sliding anti-friction gaskets 20, sliding washers 13 and flange nuts 15 form the end face sliding seal compensation structure, which is located in the external rigid connection structure Inside, the bolt hole B on the sliding flange reserves a transverse...

Embodiment 2

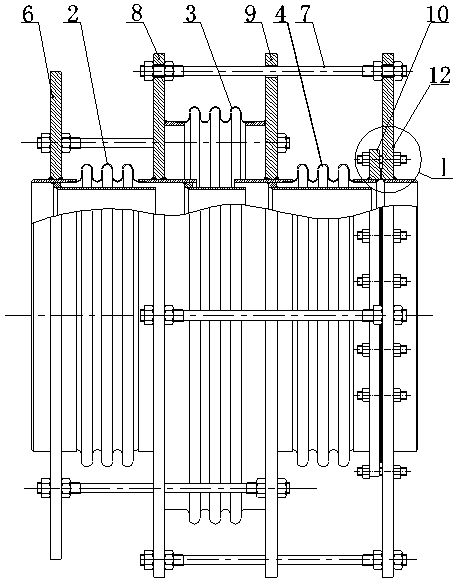

[0024] Such as image 3 A pressure-balanced expansion joint II using end-face sliding seal compensation technology is shown. This structure will image 3 The end plate II of the pressure-balanced expansion joint shown is used as the end flange B, which can shorten the installation space and save parts, and other structures are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com