Electrical connector system with enhanced terminal retention beam

An electrical connector system and connector technology, applied in the direction of connection, two-part connection device, parts of the connection device, etc., can solve the problem of unintentional disengagement of the flexible locking member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

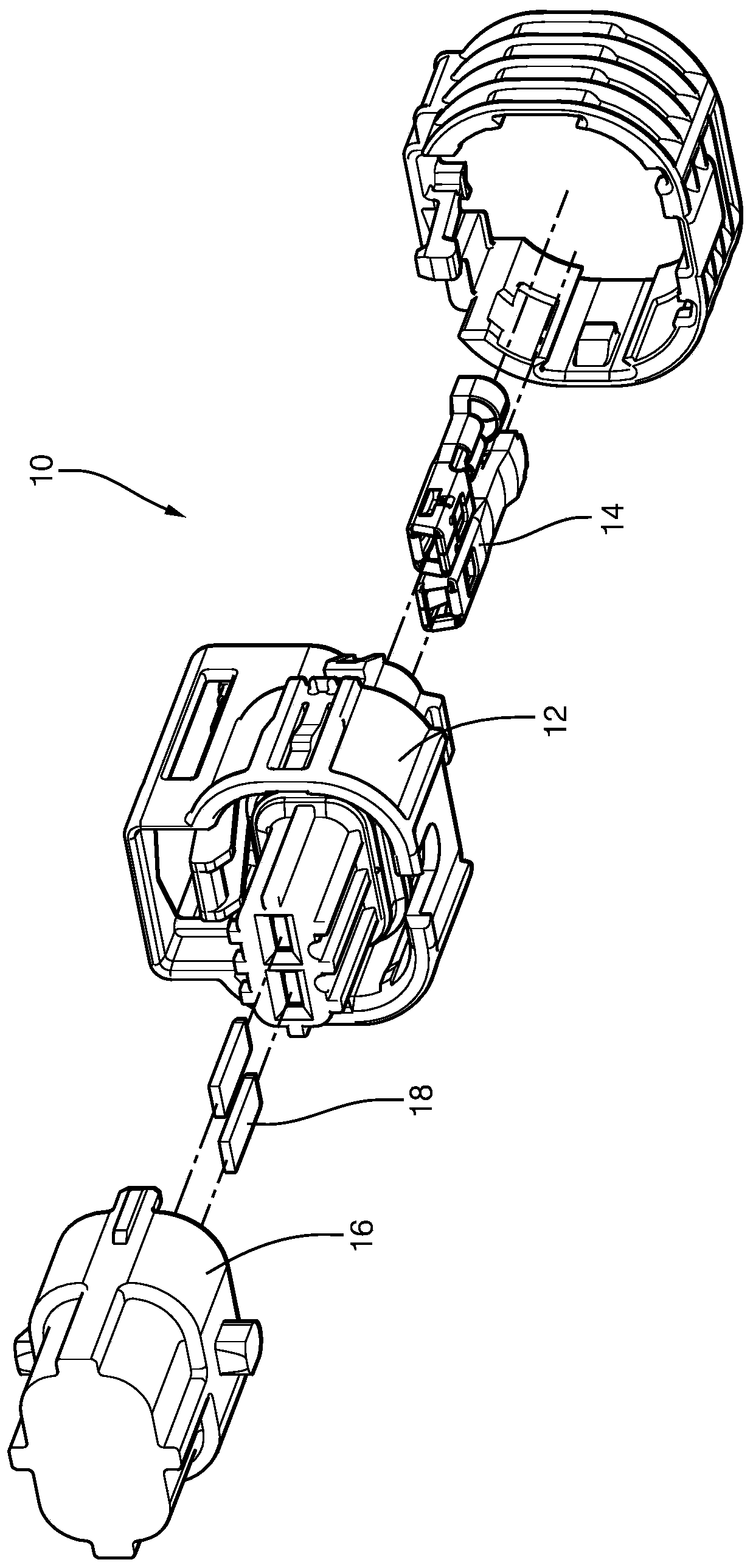

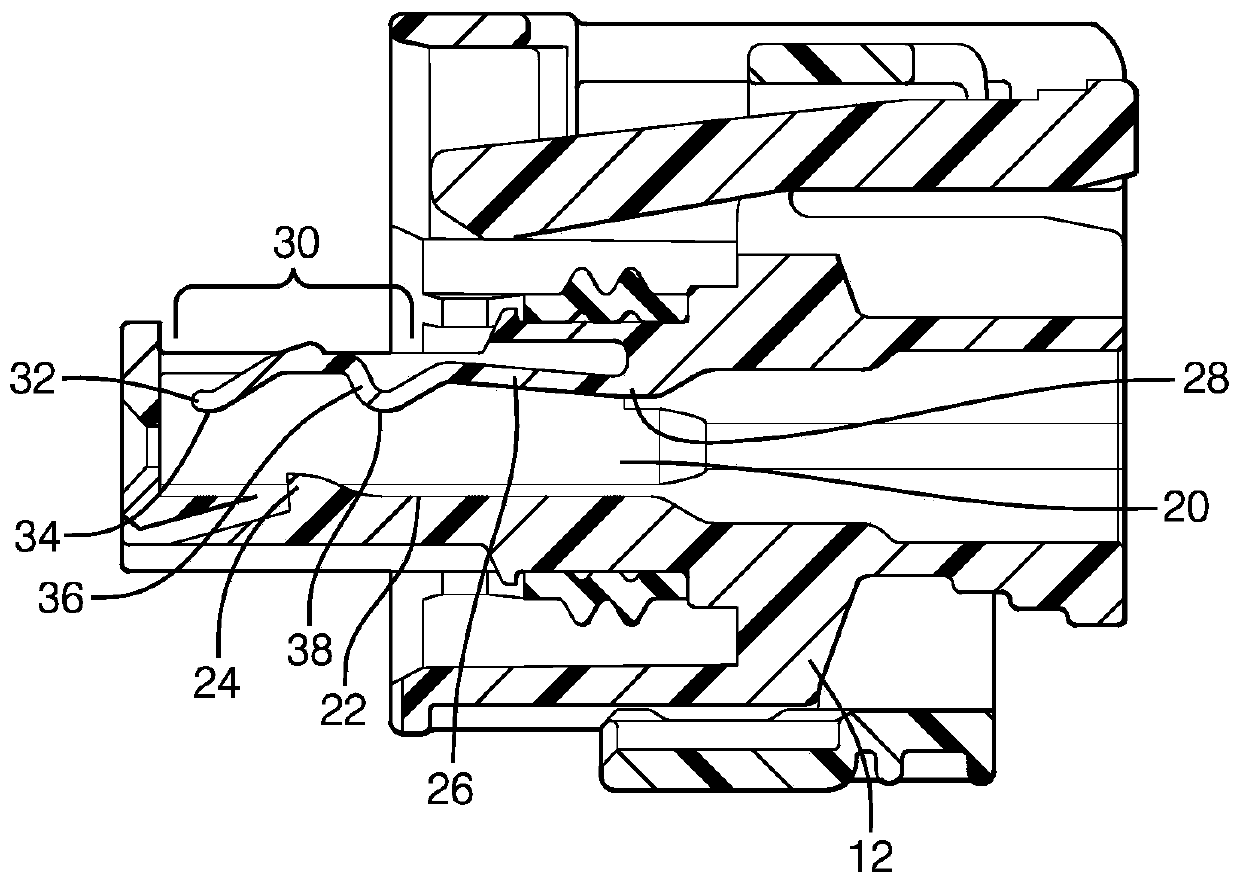

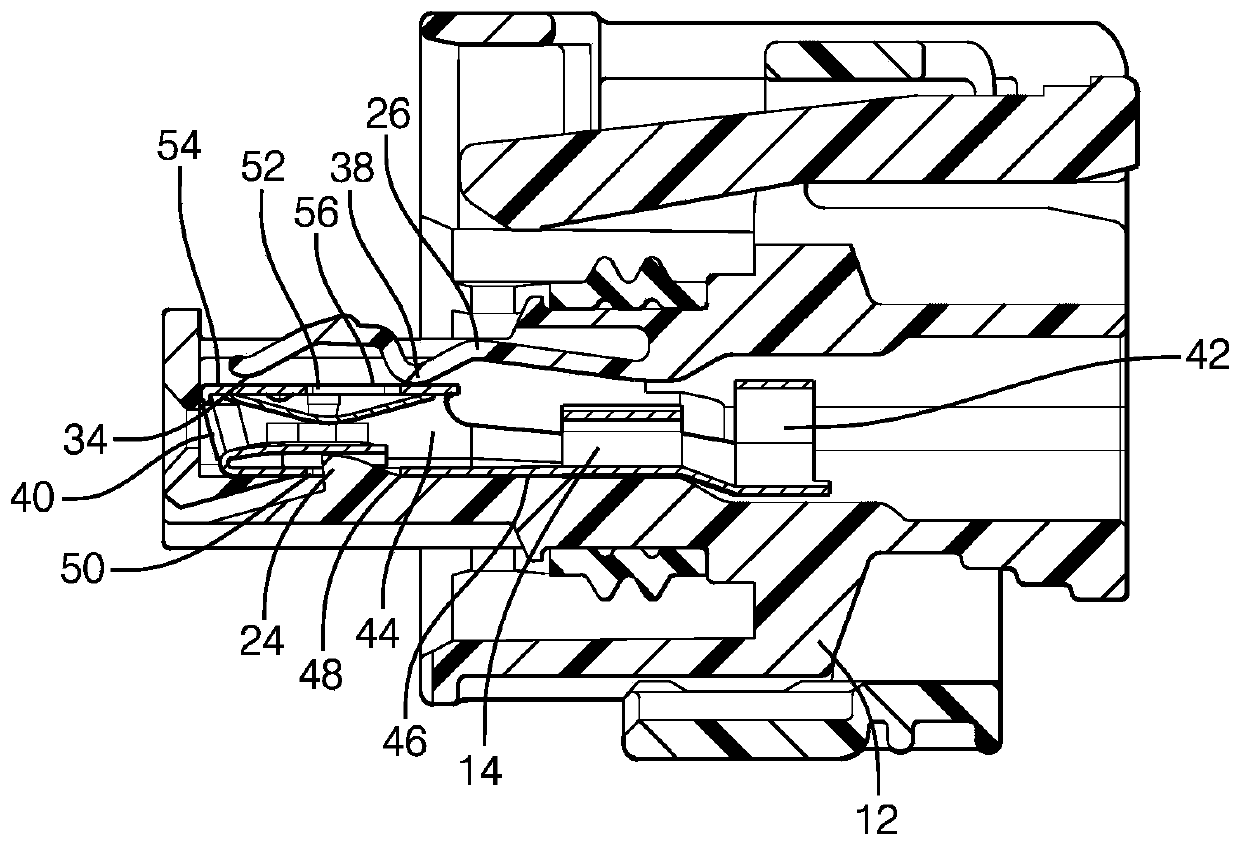

[0028] The electrical connector system described herein includes a terminal restraint beam configured to apply a spring force to a terminal disposed within a terminal cavity of the first connector body to maintain engagement of the terminal with the terminal locking prong, the engagement inhibiting the terminal out of the terminal cavity. The terminal retention beam is also configured to contact an inner surface of the shroud of the second connector body. This contact with the shroud applies an additional force to the terminal restraint beam which holds the terminal against the floor of the terminal cavity, thereby inhibiting vibration-induced relative movement between the terminal and the terminal cavity.

[0029] In the following description, terms describing orientation such as "longitudinal" will refer to the fitting axis X, while "transverse" should be understood to mean an axis perpendicular to the fitting axis X, which is not necessarily a transverse axis. Furthermore,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com