Rear double-drive different-shaft clutch

A clutch and differential shaft technology, applied in the field of electronic locks, can solve problems such as poor security and potential safety hazards of electronic locks, and achieve the effect of improving security, satisfying unlocking methods and habits, and eliminating technical unlocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

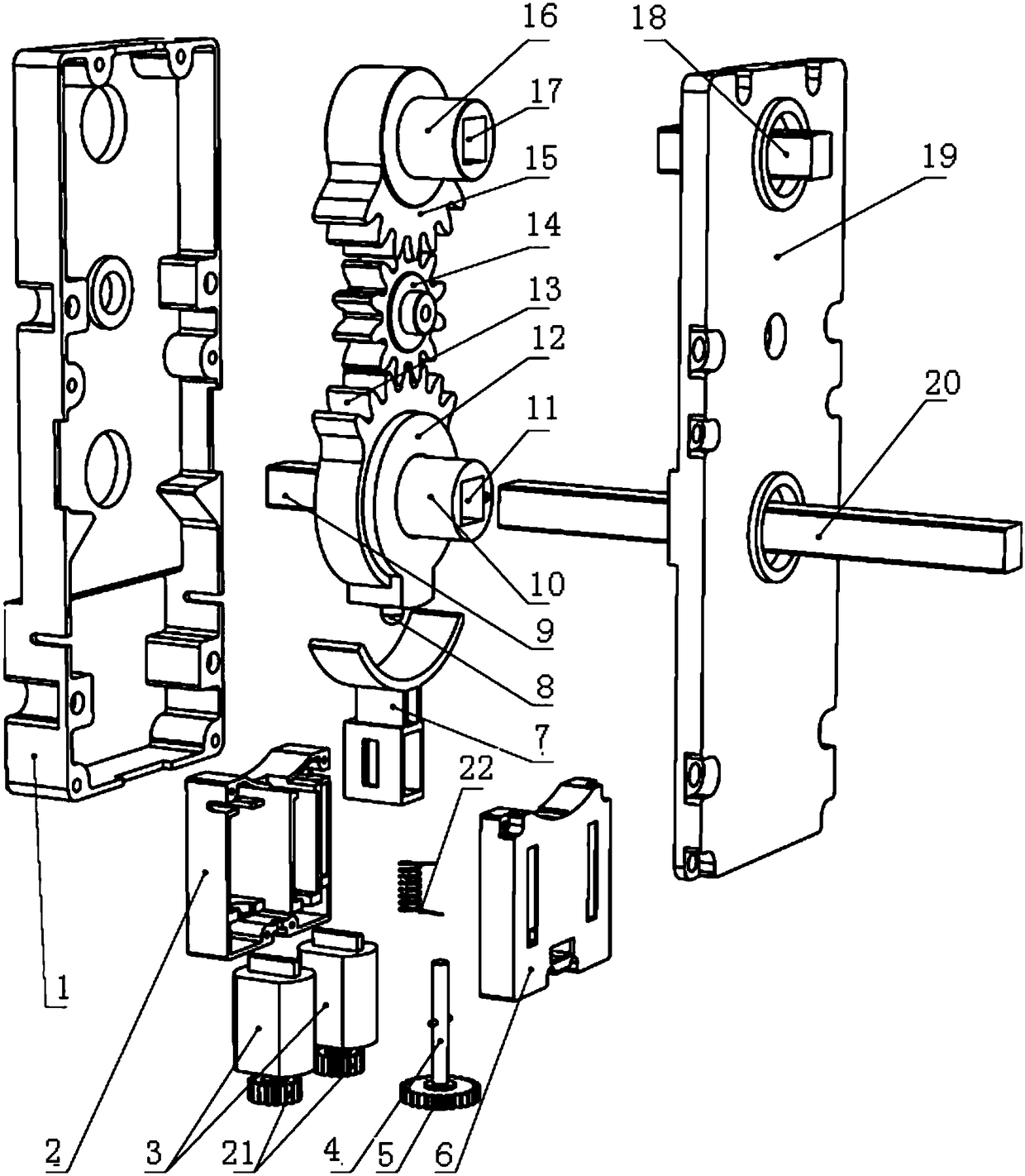

[0012] In order to make the purpose, technical solutions and advantages of the present invention clearer, further detailed description will be made below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only a preferred embodiment of the present invention, and Do not limit the scope of the present invention.

[0013] Such as figure 1 As shown, the present invention is a rear-mounted double-drive cross-axial clutch, which includes a driver, a clutch shaft, and a synchronous transmission mechanism arranged in a clutch housing. The clutch housing includes an upper housing 19 and a lower housing 1. The driver includes: two motors 3, motor gear 21, push shaft gear 5, push shaft 4, push spring 22 and push rod 7, and these parts are all arranged in the driver housing. The driver housing includes: an upper shell 6 and a lower shell 2, and the clutch shaft includes a front axle 10, a rear axle 12, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap