Safe auxiliary device for operation box

A technology of auxiliary device and operation box, which is applied in the direction of building fastening devices, wing fan fastening devices, buildings, etc. Guarantee the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In view of this, the core of the present invention is to provide an operation box safety auxiliary device, which can enable multiple equipment maintenance parties to lock the operation box, and effectively avoid the phenomenon that equipment and personnel are injured by sudden opening of the equipment under maintenance appear, thus effectively ensuring safe production.

[0025] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

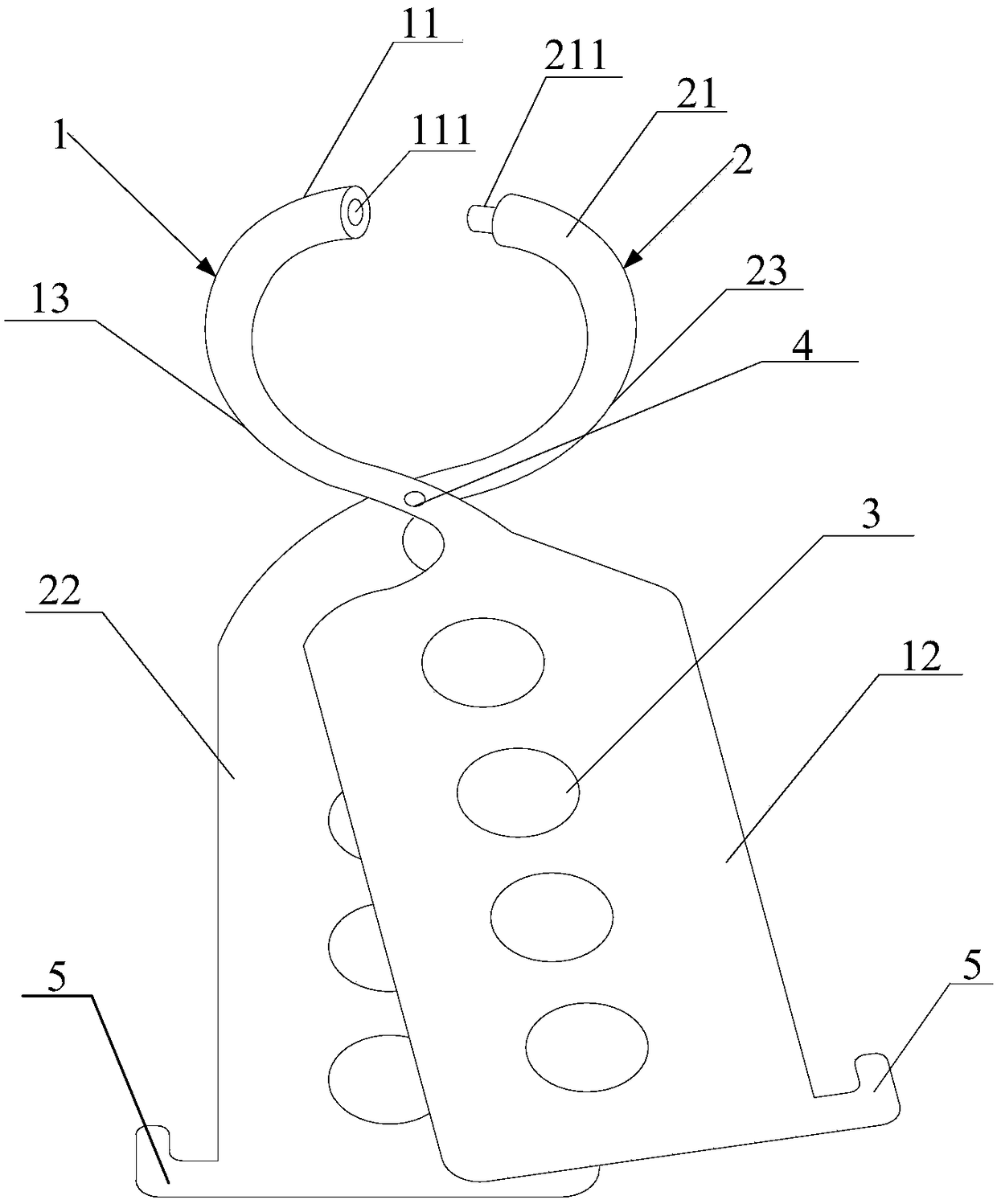

[0026] Such as figure 1 As shown, the operation box safety auxiliary device disclosed in the embodiment of the present invention includes: a first locking mechanism 1 capable of locking the door of the operation box, and a second locking mechanism 2 cooperating with the first locking mechanism 1; A locking mechanism 1 and a second locking mechanism 2 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com