Full-automatic betel nut vending machine

A vending machine, fully automatic technology, applied in instruments, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc., can solve the problem of inconvenient use, short replenishment cycle, and large labor costs and other problems to achieve the effect of reducing the frequency of restocking, reducing labor costs, and automating sales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

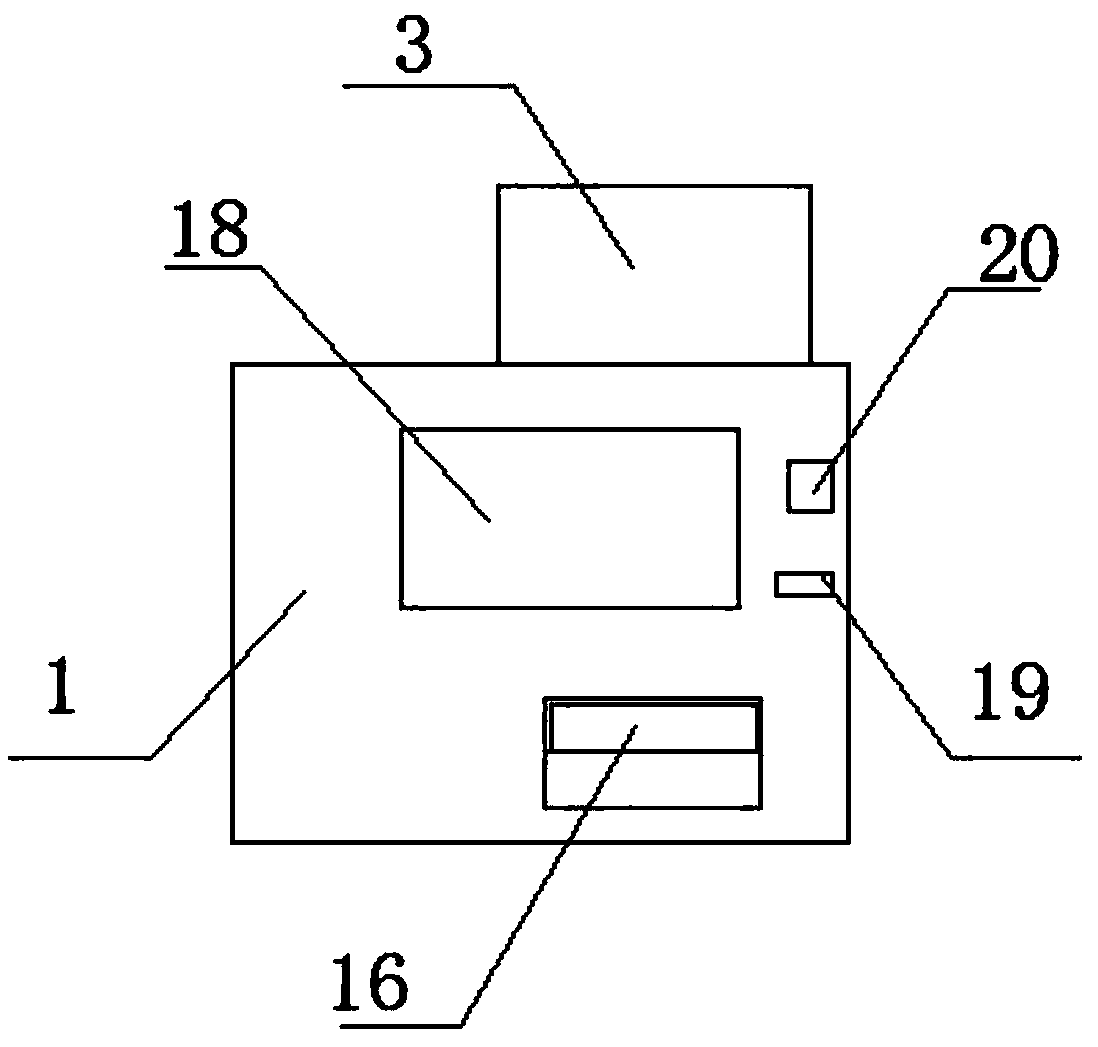

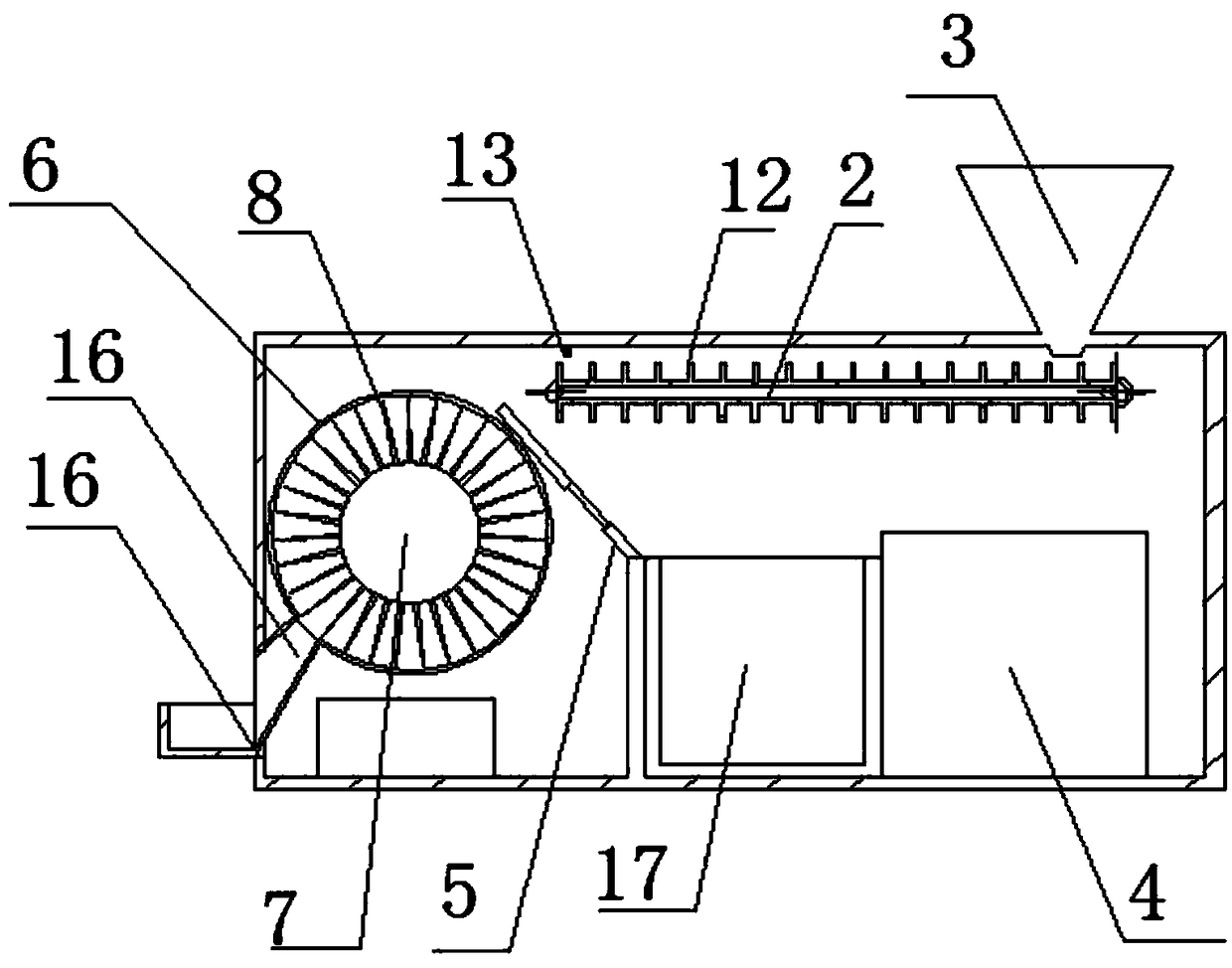

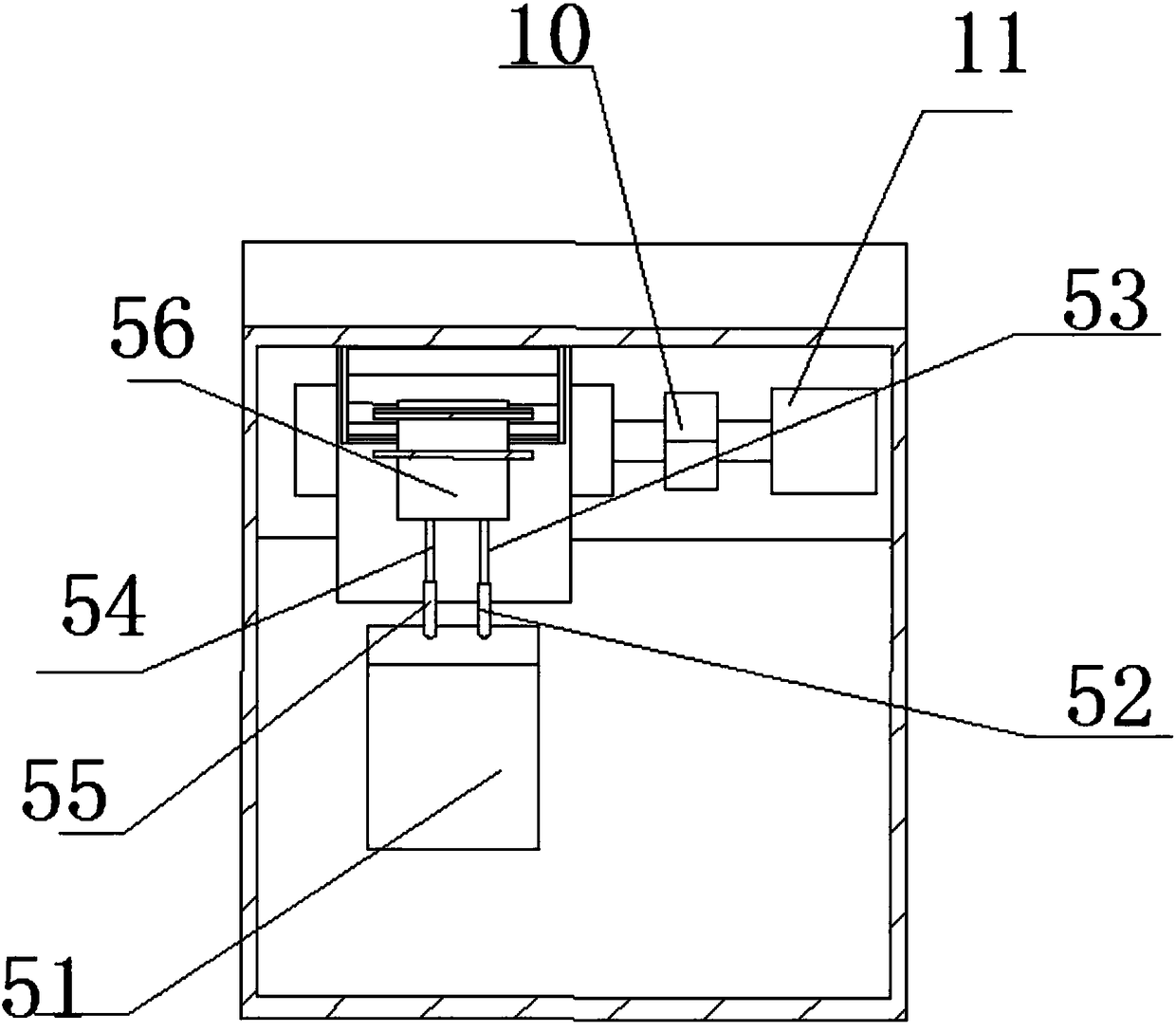

[0020] Such as Figure 1-4 As shown, a fully automatic betel nut vending machine includes a box body 1, a conveyor belt 2, a lower hopper 3, a controller 4, a kicking device 5, a lower material bucket 6, a lower material roller 7, a tooth spacer 8, and a drive shaft 9 , a transmission 10, a stepper motor 11, characterized in that: the conveyor belt 2 is in the box 1, the lower hopper 3 is above the conveyor belt 2, and the conveyor belt 2 is provided with a partition 12 , the box body 1 above the conveyor belt 2 is provided with an inductor 13, the described blanking bucket 6 is on one side of the conveyor belt 2, the described blanking roller 7 is inside the blanking bucket 6, and the described The spacer teeth 8 are arrayed on the blanking roller 7, the top of the blanking barrel 6 is provided with a feed inlet 14, and the bottom of the blanking barrel 6 is provided with a discharge port 15, and the blanking roller 7 is installed on On the transmission shaft 9, the transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com