Full-automatic wire distribution device for enameled wire equipment

A technology of automatic wire separation and enameled wire, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of high cost and opening the oven, and achieve the effect of low cost and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to illustrate the technical solution of the present invention more clearly, the accompanying drawings that need to be used in the description will be briefly introduced below. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention. As far as people are concerned, other embodiments can also be obtained according to these drawings on the premise of not paying creative work.

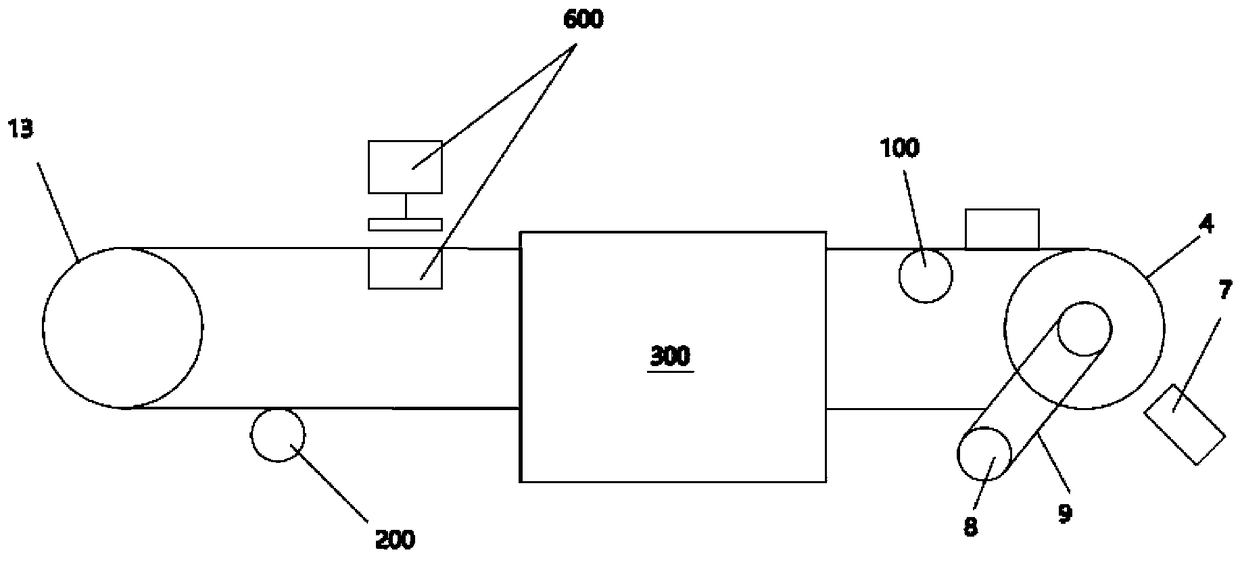

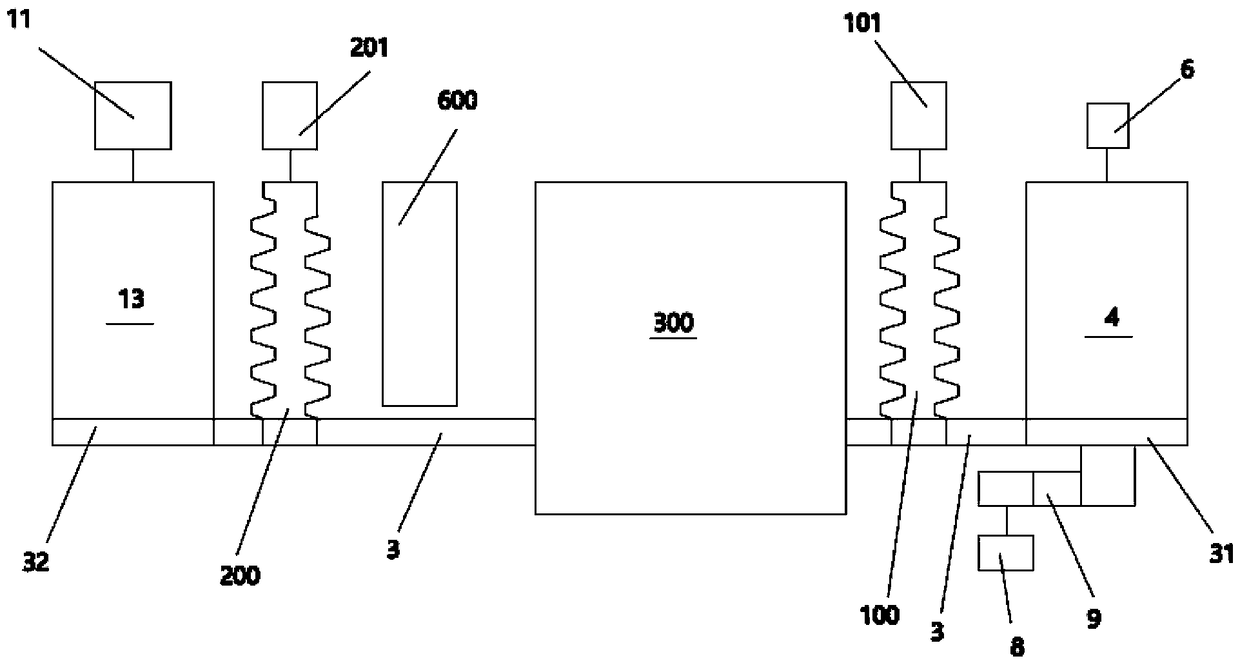

[0025] Such as figure 2 , image 3 Shown:

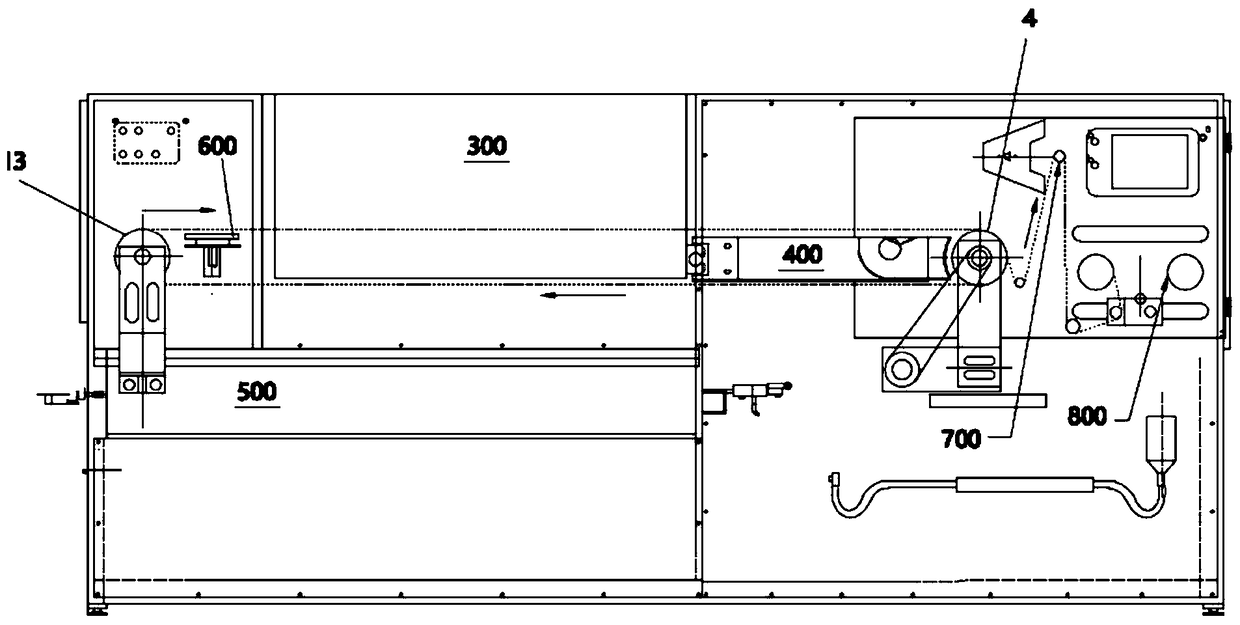

[0026] The present invention is the same as the prior art in that it consists of an oven 300 , a cooling zone 400 , an annealing furnace 500 , a painting part 600 , a constant tension system 700 , and a wire winding system 800 .

[0027] It also includes the wire feeding roller 4 at the exit and the wire feeding roller 13 at the painting part. The front servo motor 6 is connected to and drives the wire feeding roller 4 at the exit, the rear servo motor 11 is connected to and drives th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap