Fully automatic branching system for enameled wire equipment

A technology of automatic splitting and enameled wire, applied in electrical components, circuits, insulating conductors/cables, etc., can solve the problems of high labor intensity, waste of electric energy, and high requirements for operating skills, improve work efficiency, and get rid of manual operation of splitting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

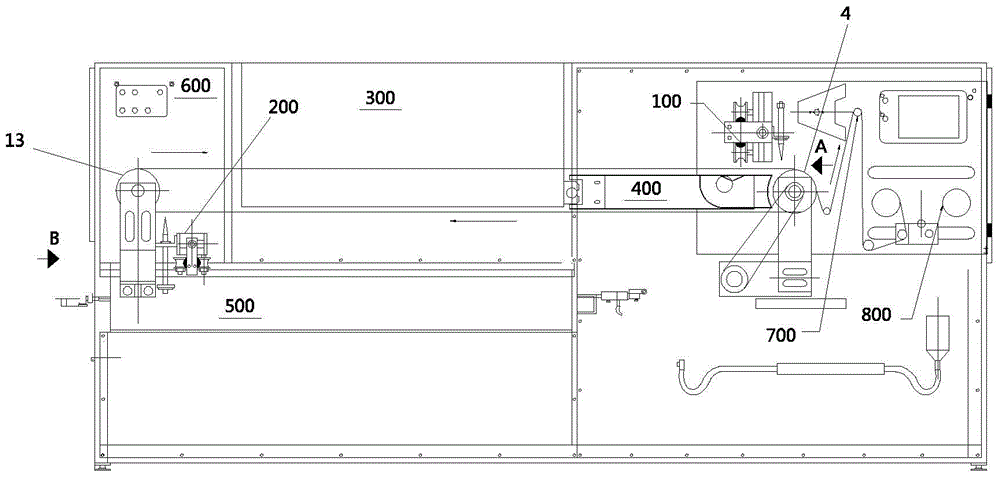

[0020] Such as figure 1 As shown, the present invention is the same as the prior art in that it consists of an oven 300 , a cooling zone 400 , an annealing furnace 500 , a painting part 600 , a constant tension system 700 , and a wire winding system 800 .

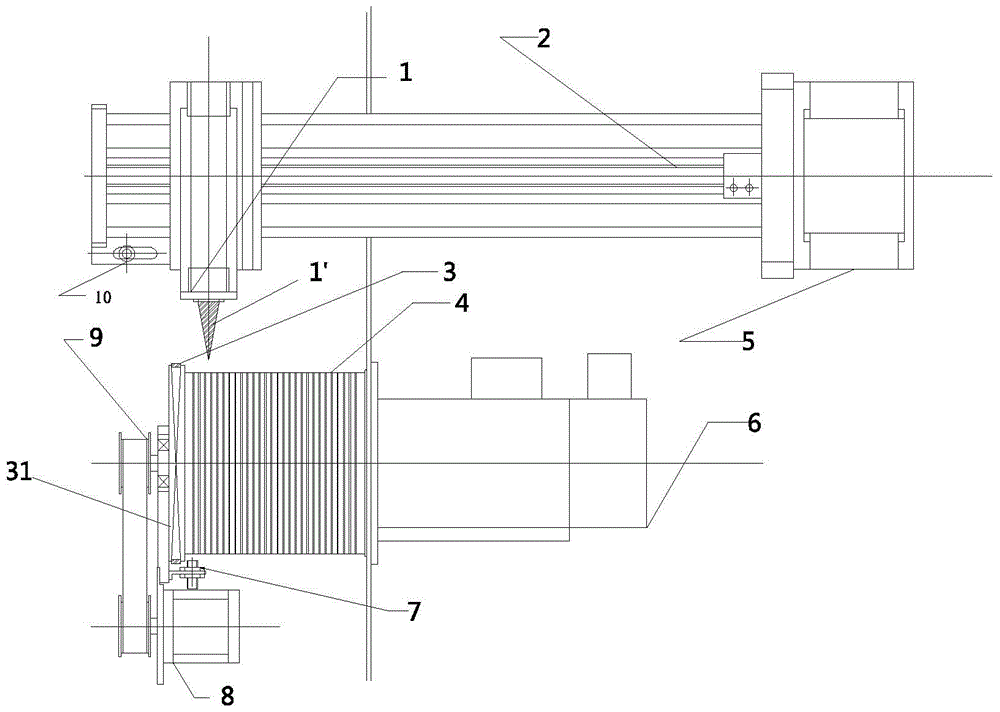

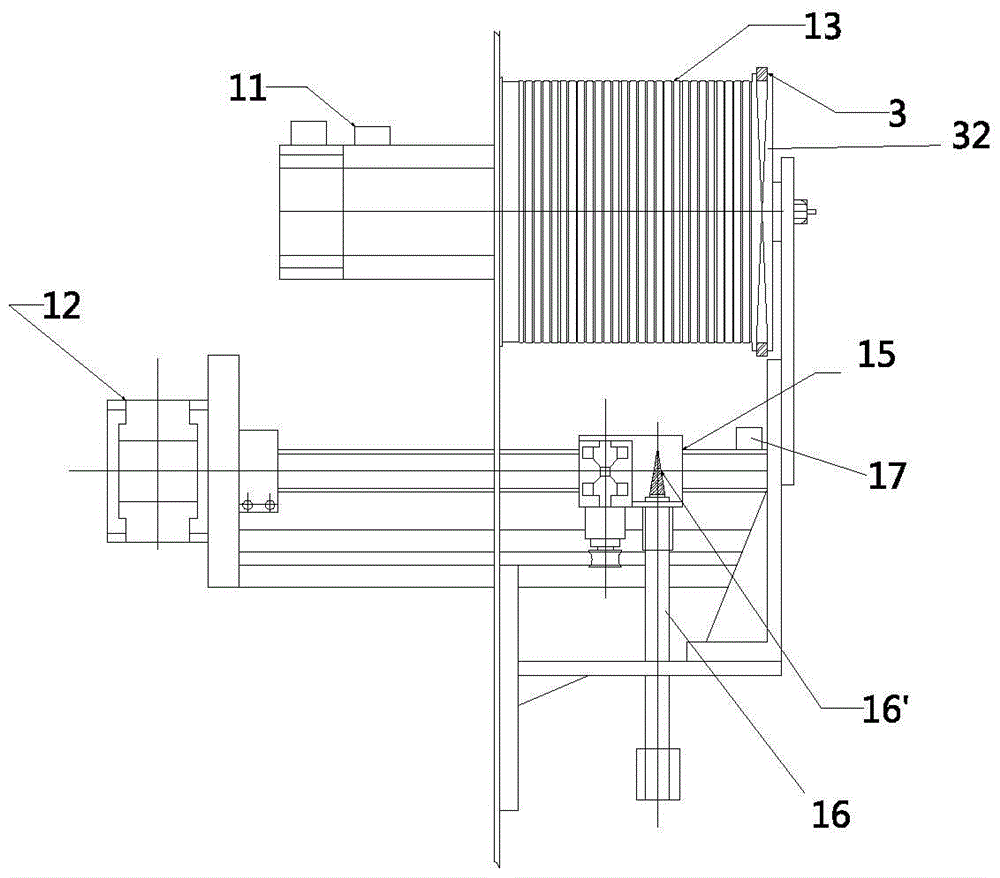

[0021] It also includes the wire feeding roller 4 at the exit and the wire feeding roller 13 at the painting place. The front servo motor 6 is connected to and drives the wire feeding roller 4 at the exit, the rear servo motor 11 is connected to and drives the wire feeding roller 13 at the painting place, and the lead steel strip 3 Wound on the reel 31 coaxial with the wire feeding drum 4 at the exit and the reel 32 coaxial with the wire feeding drum 13 at the painting place, the steel strip running motor 8 is connected with the conveyor belt 9 and drives the lead wire steel strip 3 .

[0022] The invention has a rack to mount the components.

[0023] Compared with the prior art, the present invention increases figure 1 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com