Patents

Literature

44results about How to "Get rid of manual operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

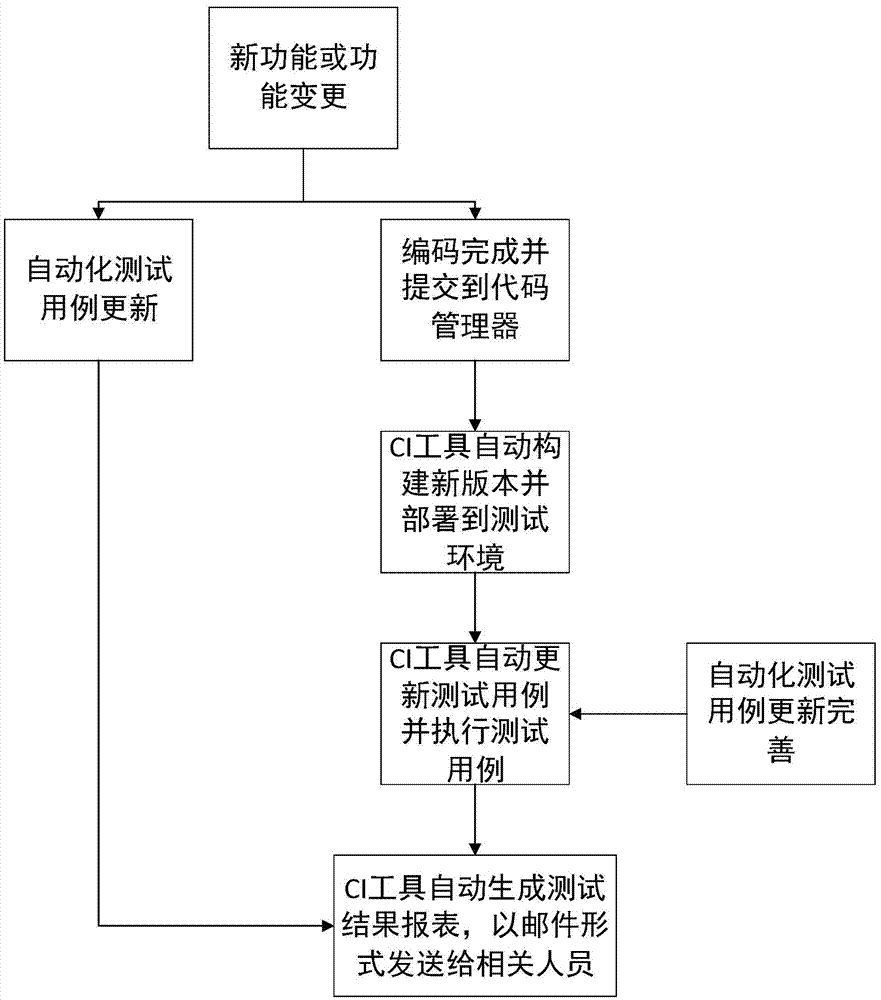

Continuous program automated testing method

ActiveCN105446878AGet rid of manual intervention processGet rid of manual operationSoftware testing/debuggingSoftware engineeringAutomatic testing

Owner:EISOO SOFTWARE

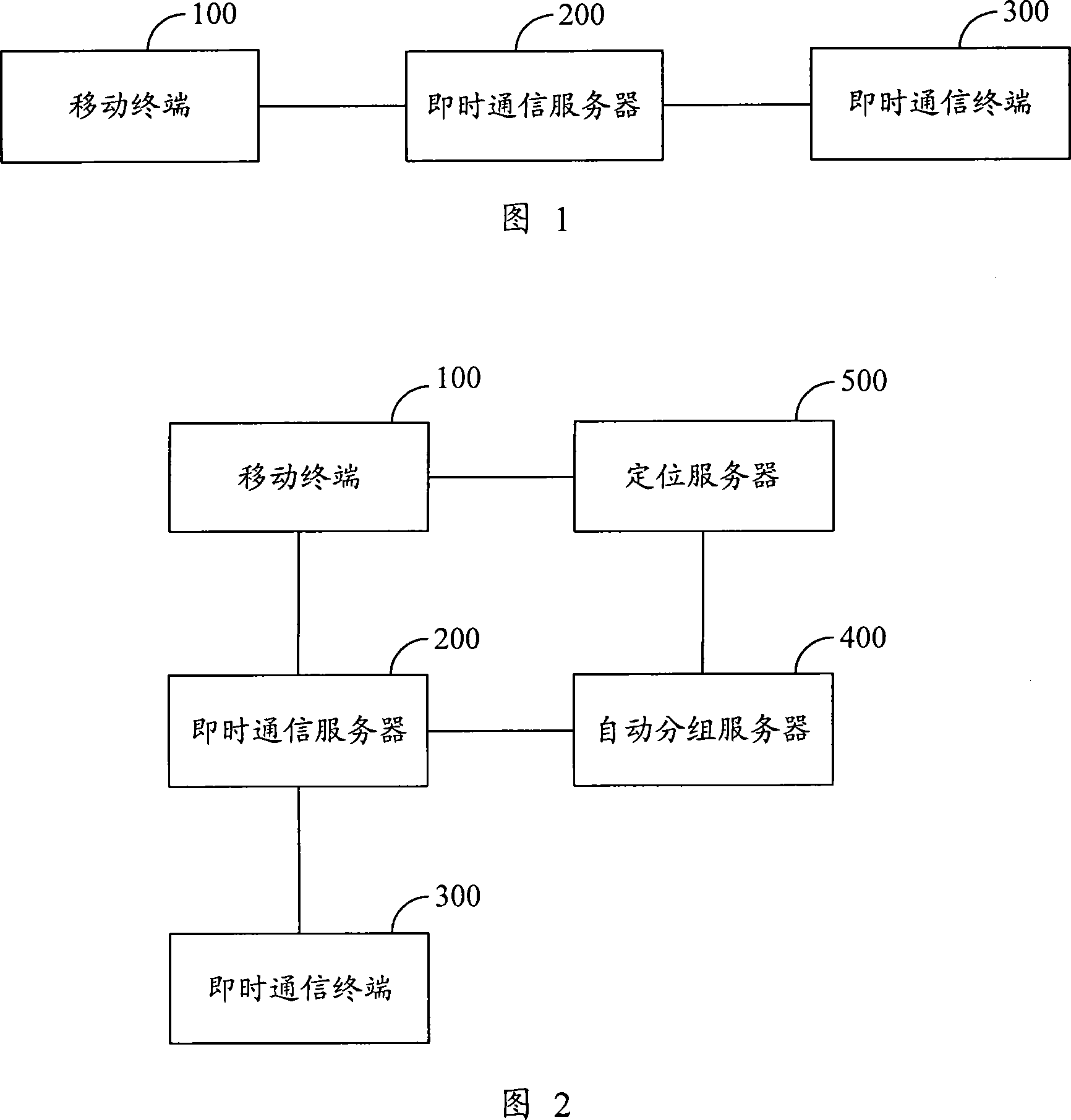

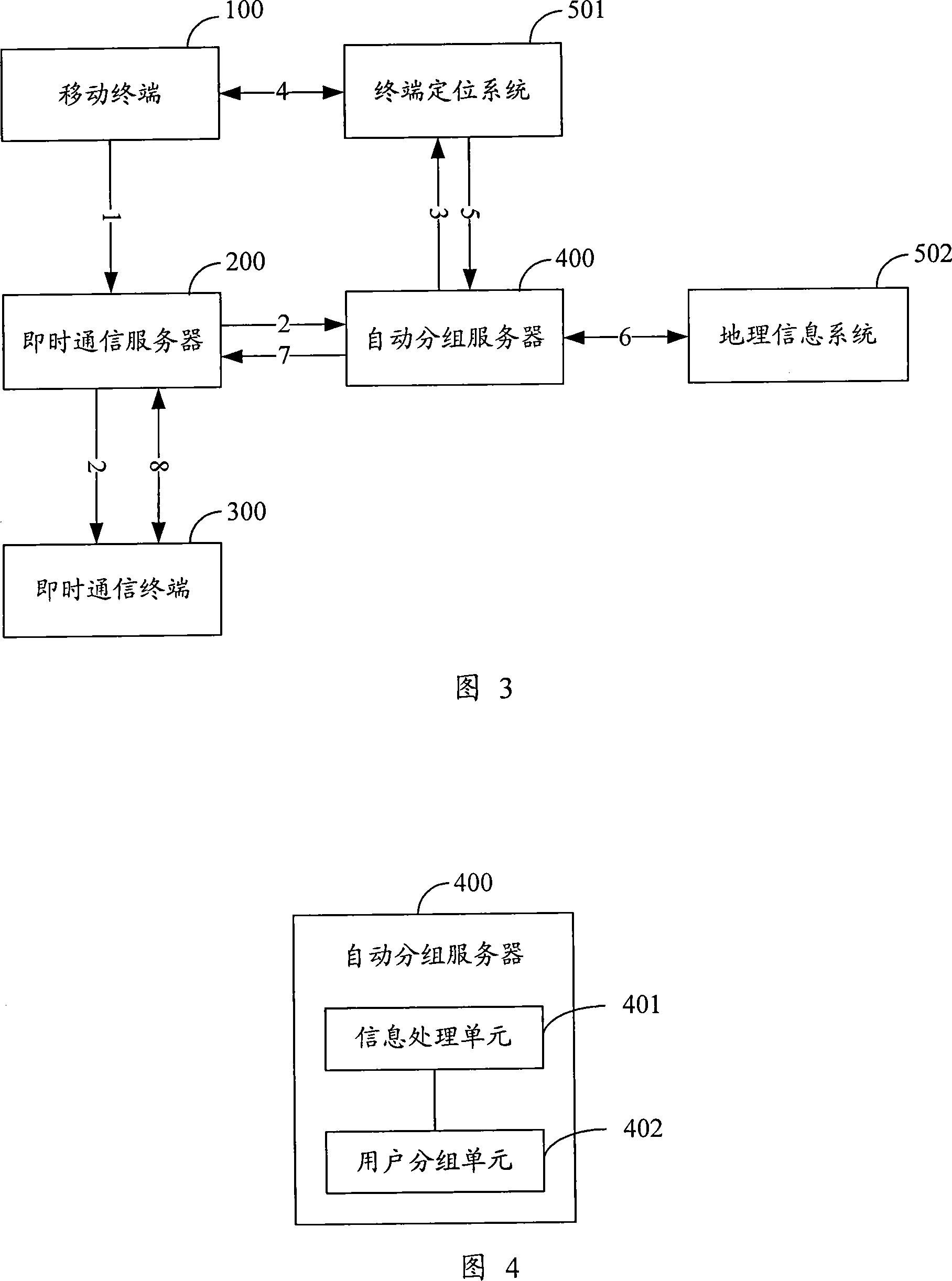

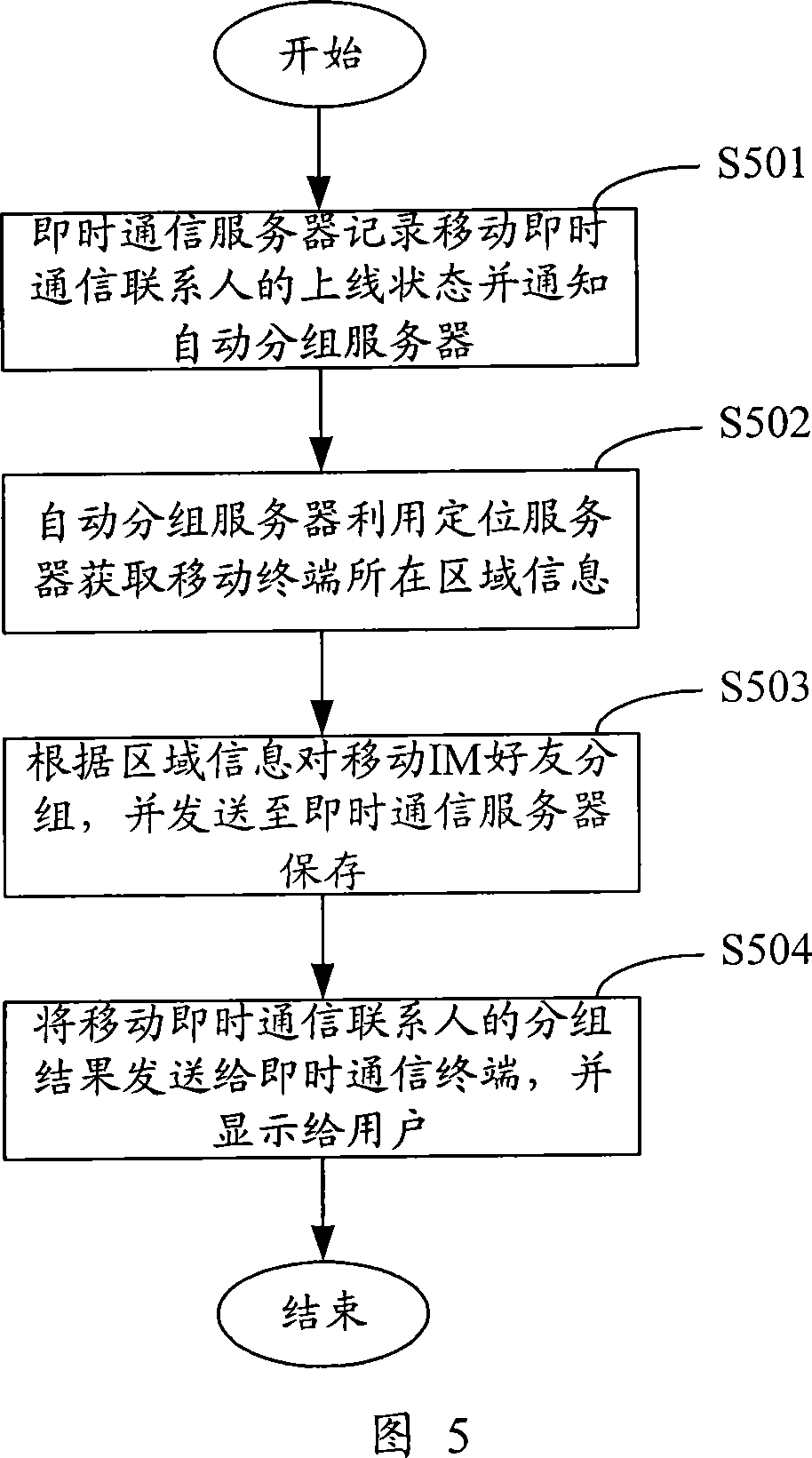

A method, system and device for grouping mobile instant communication contacts

InactiveCN101127735AImprove accuracyGet rid of manual operationInformation formatServices signallingComputer scienceCommunications server

The utility model relates to a method, system and a piece of equipment to group the connecting persons of mobile and instant communication, belonging to the communication field. The system comprises a mobile terminal, an instant communication terminal and an instant communicational server which applies communicational service to users and the connecting persons with mobile and instant communication and presents the grouping information of the connecting persons of mobile and instant communication to the users. The system also comprises an automatic grouping server and a positioning server which searches the area information of the mobile terminal and feedbacks the information to the automatic grouping server; the area information of the mobile terminal from the positioning server is obtained and the connecting persons of mobile and instant communication according to the area information is grouped by the automatic grouping server. The utility model has the advantages of improving the grouping accuracy and breaking through the grouping efficiency.

Owner:TENCENT TECH (SHENZHEN) CO LTD

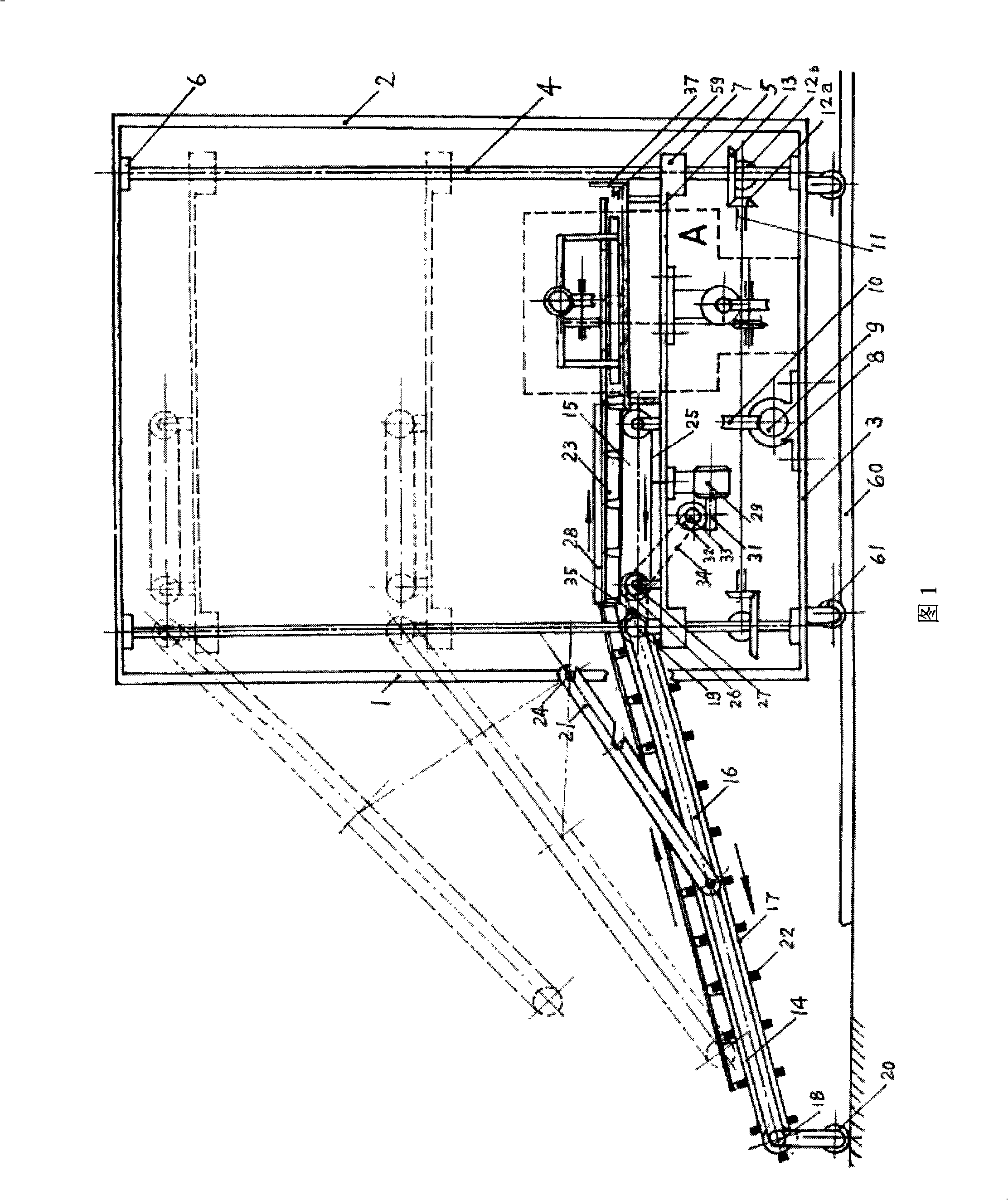

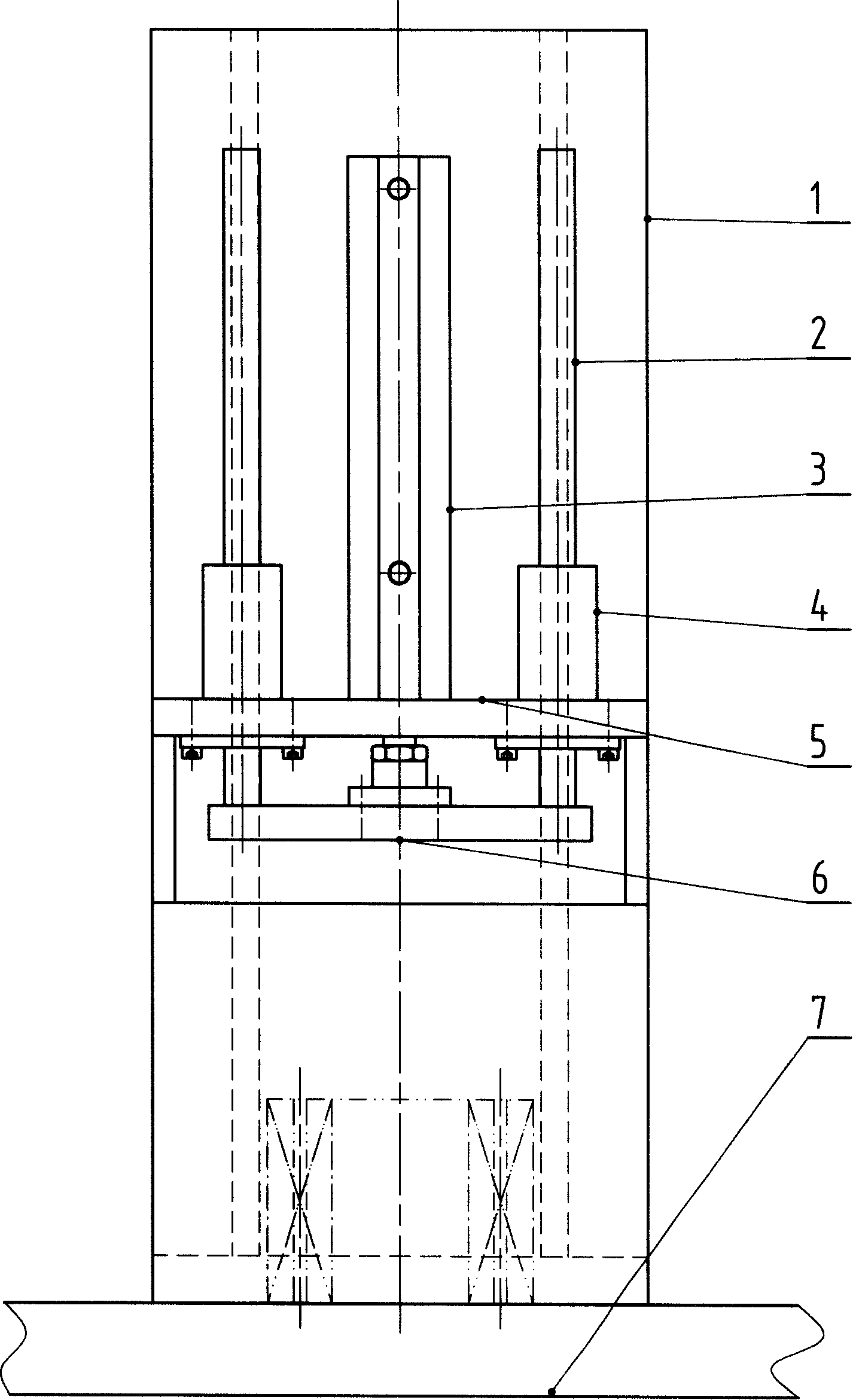

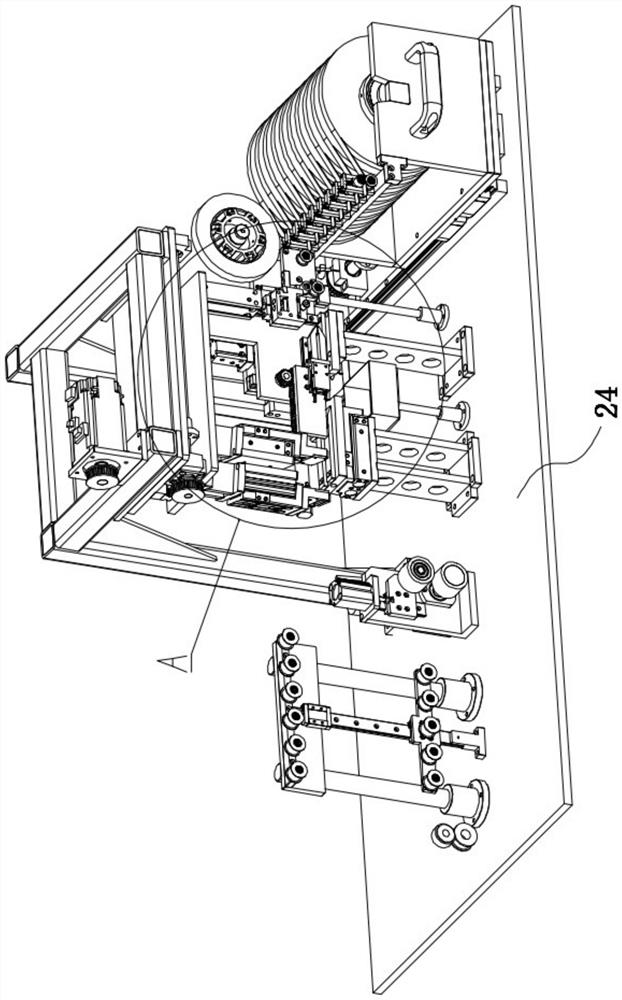

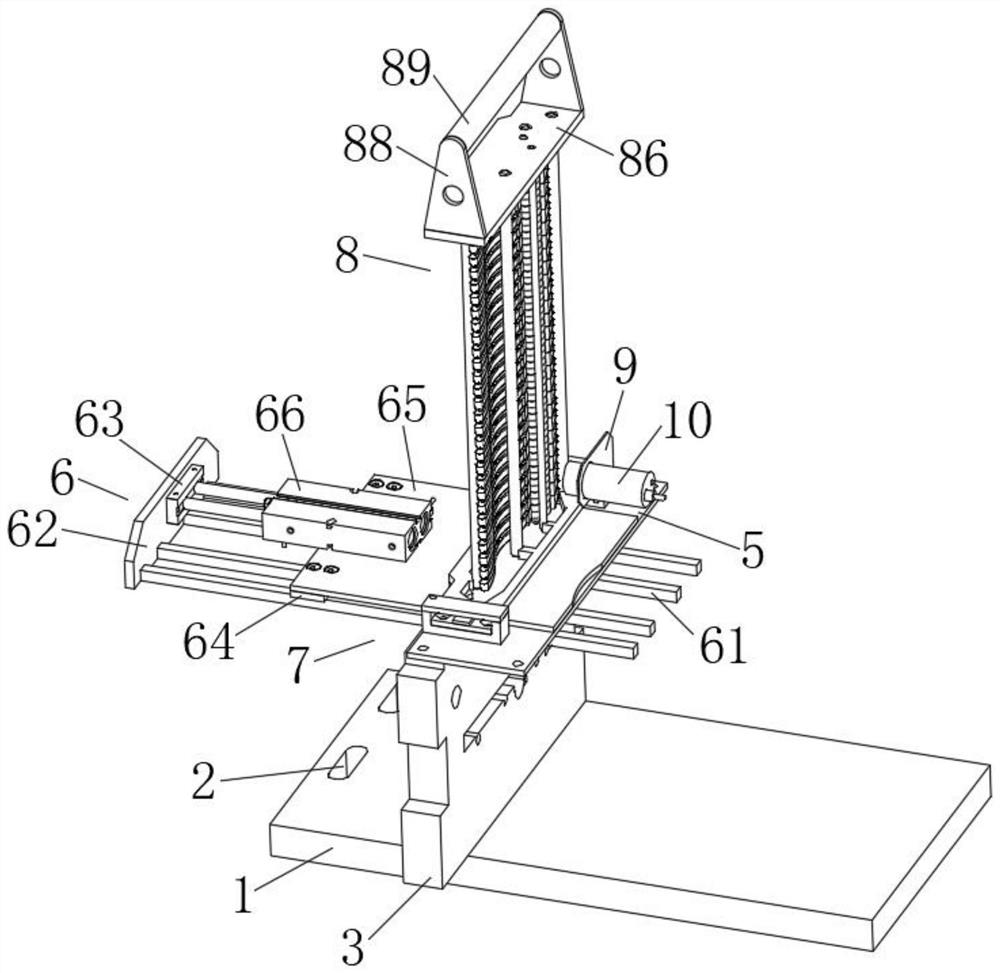

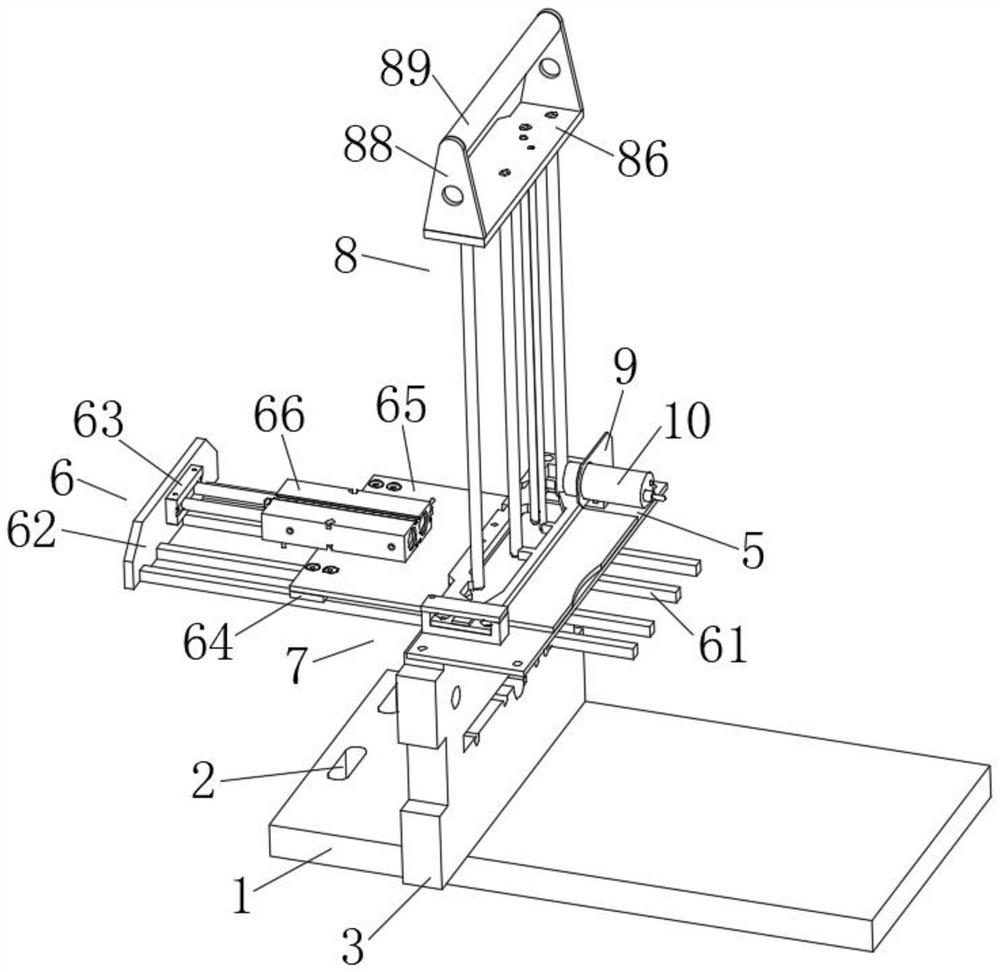

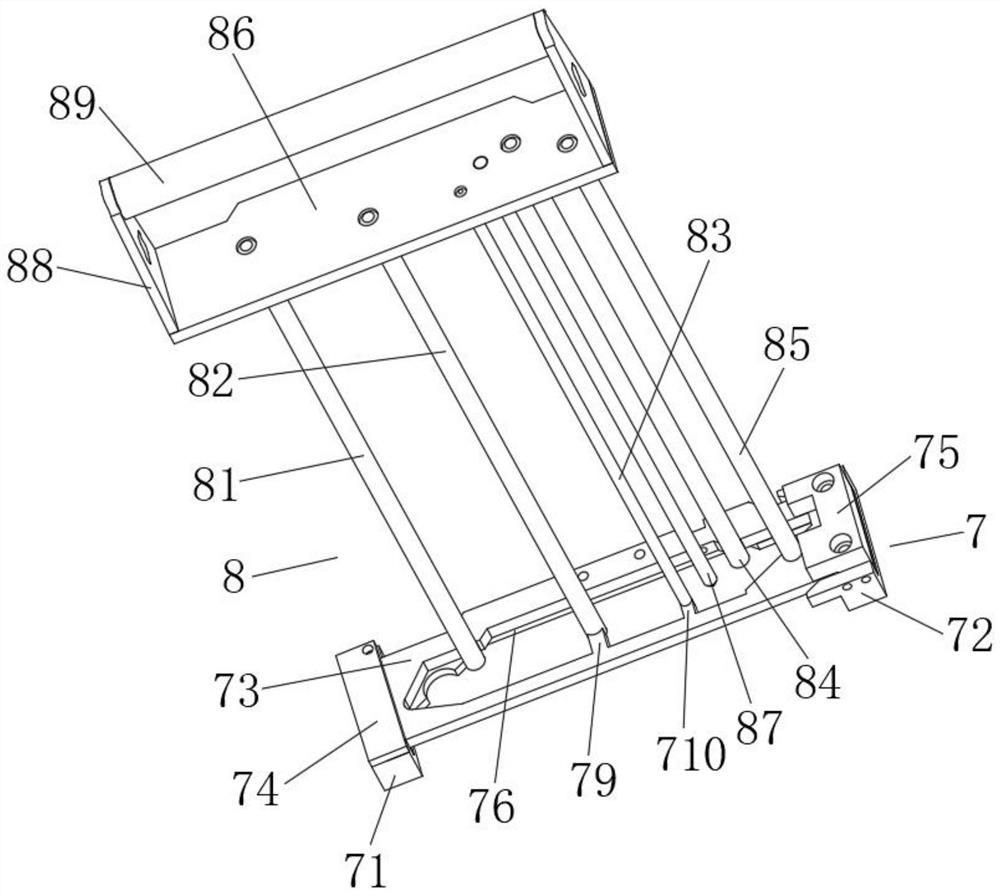

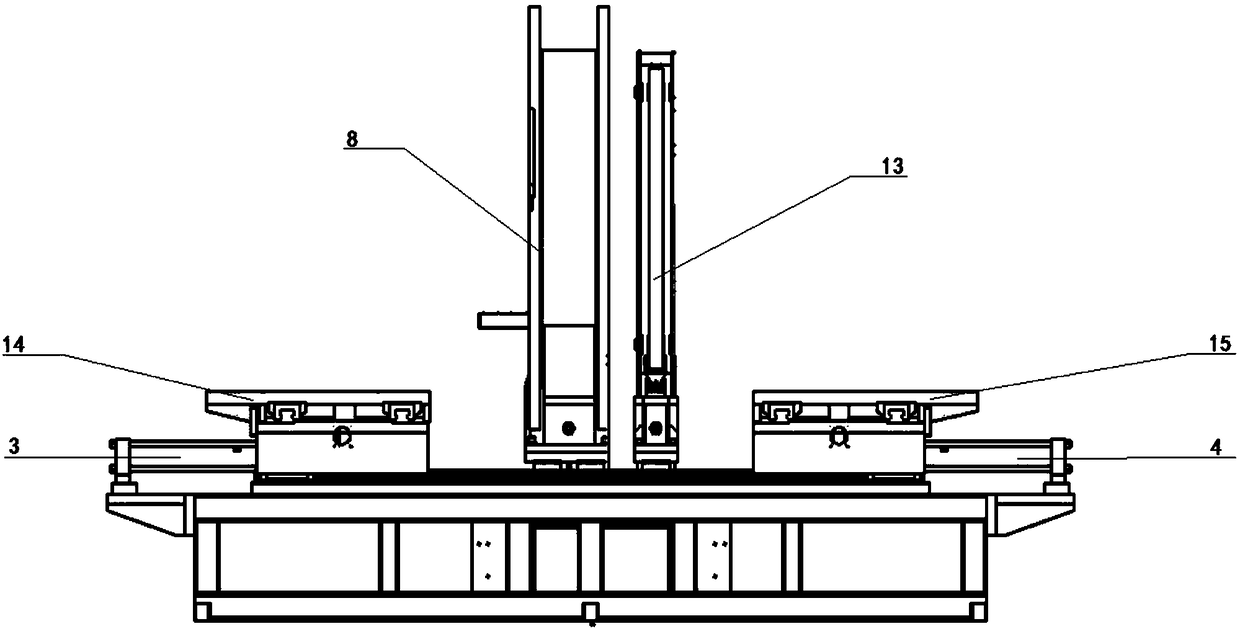

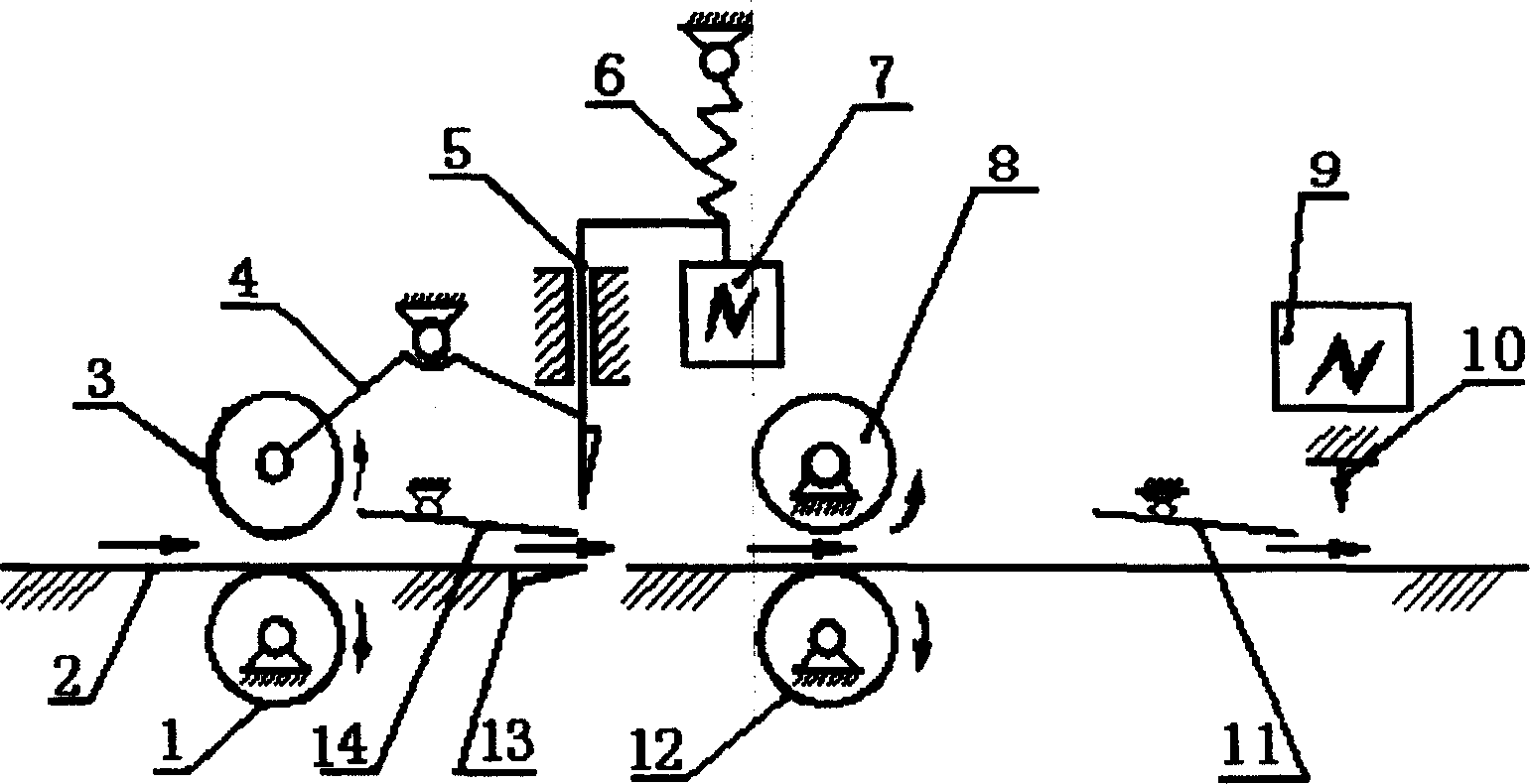

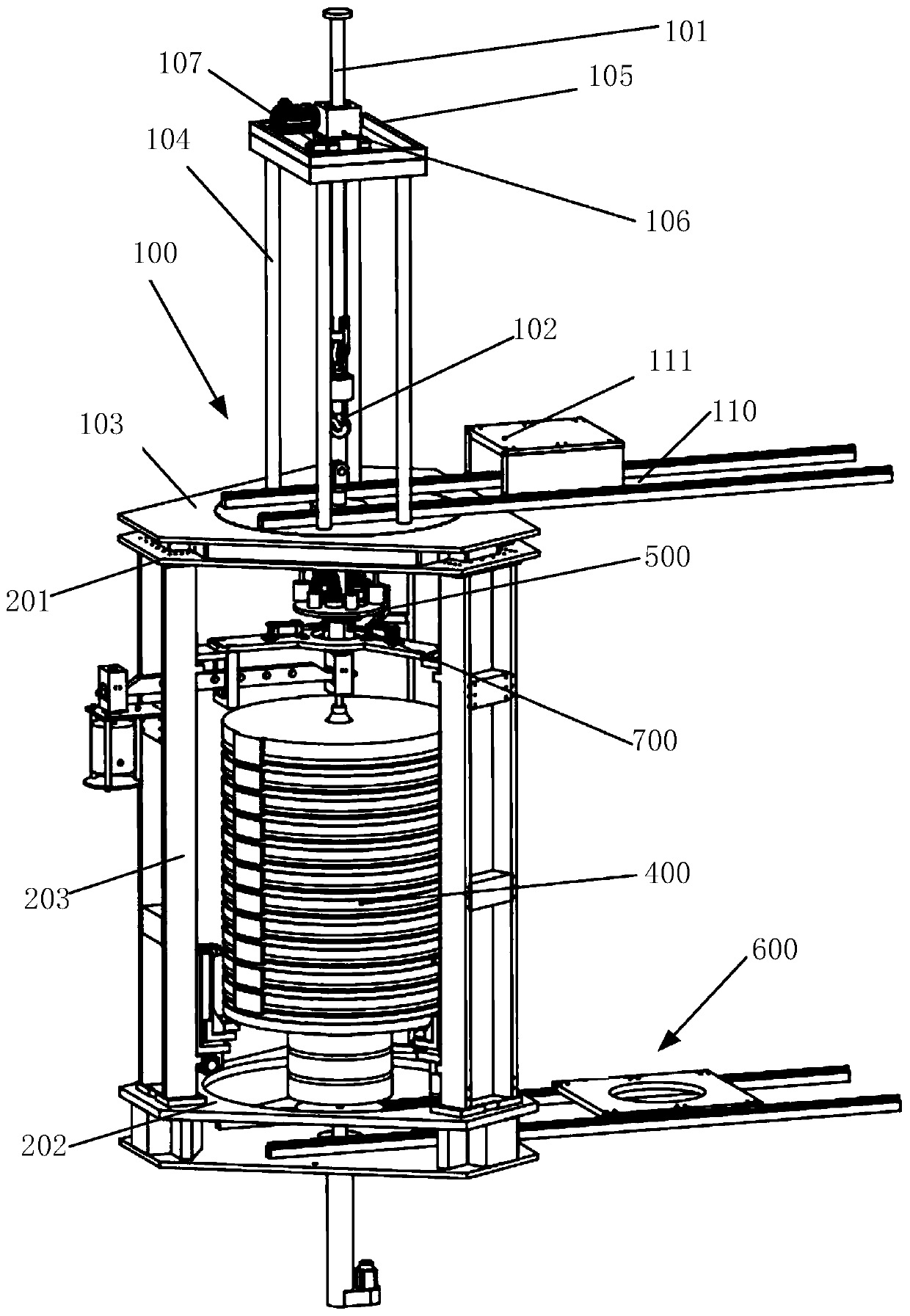

Movable growth disk installation device for aerosol stereo planting production

InactiveCN101336607ASimple structureEasy to operateLifting framesAgriculture gas emission reductionEngineeringHigh intensity

The present invention discloses a movable type top carriage device for a growth disk applied to cubic aeroponics production. The movable type top carriage device for the growth disk is composed of a frame, a lifting platform mechanism, a growth disk delivering mechanism, a growth disk feeding mechanism and a movable mechanism; the lifting platform is led to lift along four screw rods by means of power transmission; the growth pot delivering mechanism delivers the growth pot to the lifting platform via a big conveyor belt, and to the feeding platform via a small conveyor belt; the feeder of the growth disk delivering mechanism feeds the growth disk on the feeding platform into a top carriage slide rail; the movable mechanism comprises two parallel rails and four casters mounted at the bottom of the frame. The present invention has the advantages of simple structure, easy operation, low manufacturing cost; as the growth disk adopts automatic top carriage, manual operation with high intensity can be shaken off, which is convenient for the standardized management, and greatly improves the production efficiency; the device combined with the aeroponics industrial production device provided with the automatic delivering mechanism of the growth disk, is utilized, thereby realizing the automation of under carriage and top carriage of growth disk in the cubic aeroponics production.

Owner:慕山君

Method for setting mobile communication concession section

InactiveCN101404795AFlexible adjustment of discount rangeGet rid of manual operationAccounting/billing servicesTelephonic communicationData informationWireless network

The invention discloses a method for setting a mobile communication favorable area, which comprises three parts: determining a favorable area initial point of a user, setting a favorable subdistrict list of the user by automatically calculating, self-correcting the favorable subdistrict list of the user after a wireless network is adjusted. The method counts data based on data information of a planning subdistrict and switching relationship of the existing network subdistrict and realizes automatically calculation of the favorable subdistrict list of the user. Compared with a zone charging way realized by corresponding relation between the subdistrict and the charging set by manpower, the method fully breaks away from manual operation, and is fully finished by automatically calculating of a server; therefore, zone favorable service individually customized by a user; can be realized and an operator can flexibly adjust favorable range by adjusting the size of the favorable subdistrict list.

Owner:CHINA MOBILE GROUP JIANGSU

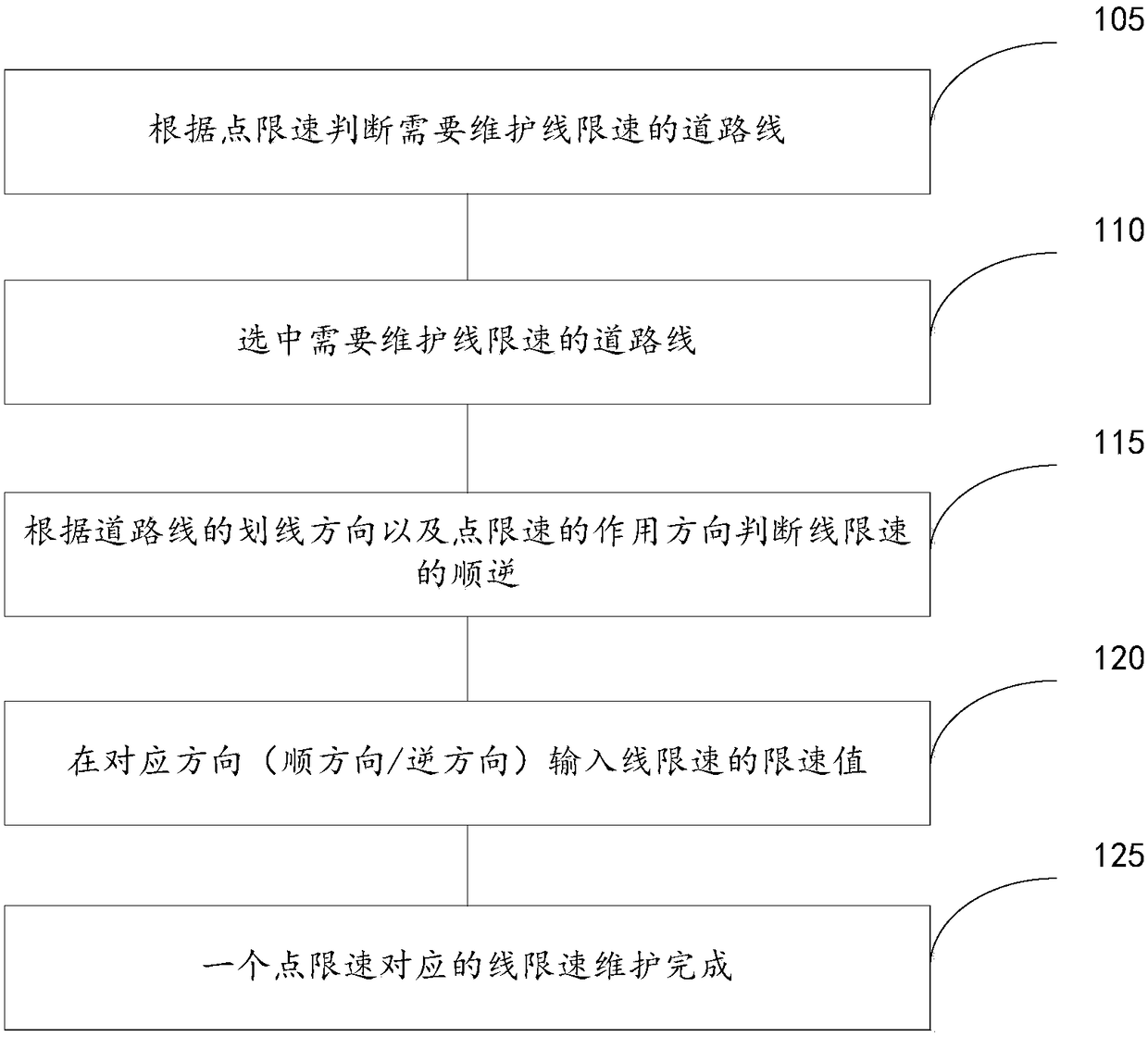

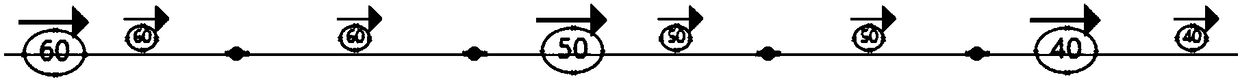

Automatic assignment method and device, intelligent electronic map production system and navigation equipment

ActiveCN108241623AAvoid the pitfalls of line speed limit maintenanceAvoiding pitfalls of rate-limited maintenanceInstruments for road network navigationRoad vehicles traffic controlBatch processingComputer science

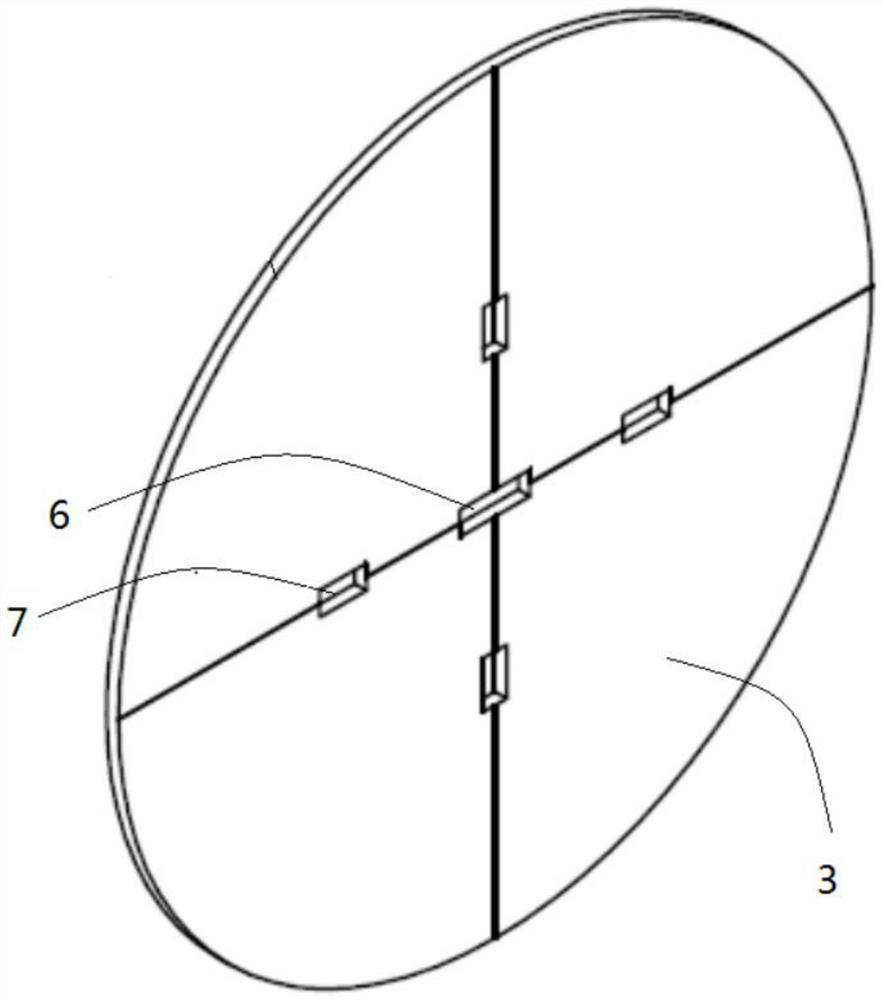

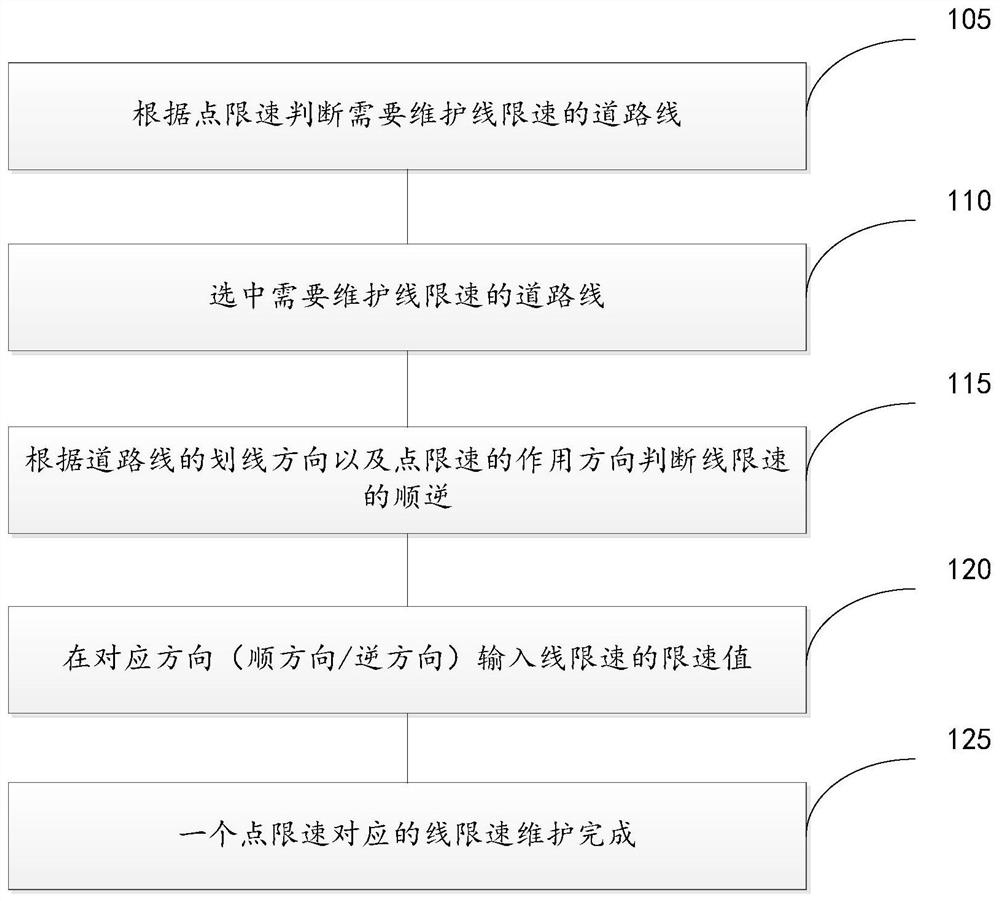

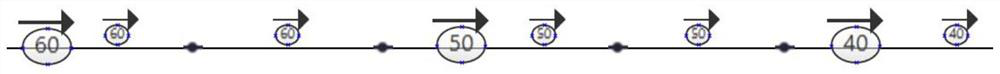

The invention discloses an automatic assignment method and device for line speed limit, an intelligent electronic map production system and navigation equipment. The method comprises the following steps of: obtaining a point speed limit value in a road and a point speed limit direction corresponding to the point speed limit value; determining a to-be-assigned start road line and a tracking direction on the basis of a preset automatic tracking principle, planning a tracking path and determining a to-be-assigned termination road line; and determining a direction of a line speed limit value of the tracked road line according to a lineation direction of the tracked road line and the point speed limit direction corresponding to the point speed limit value, and automatically carrying out line speed limit assignment on the tracked road line according to the point speed limit value and the direction of the line speed limit value of the tracked road line. According to the automatic assignment method, maintenance of line speed limit can get rid of heavy manual operation, line speed limit assignment can be completed through automatically tracking each road line, and batch processing can be carried out on one section of road, so that the defect of carrying out line speed limit maintenance on road lines one by one is avoided.

Owner:NAVINFO

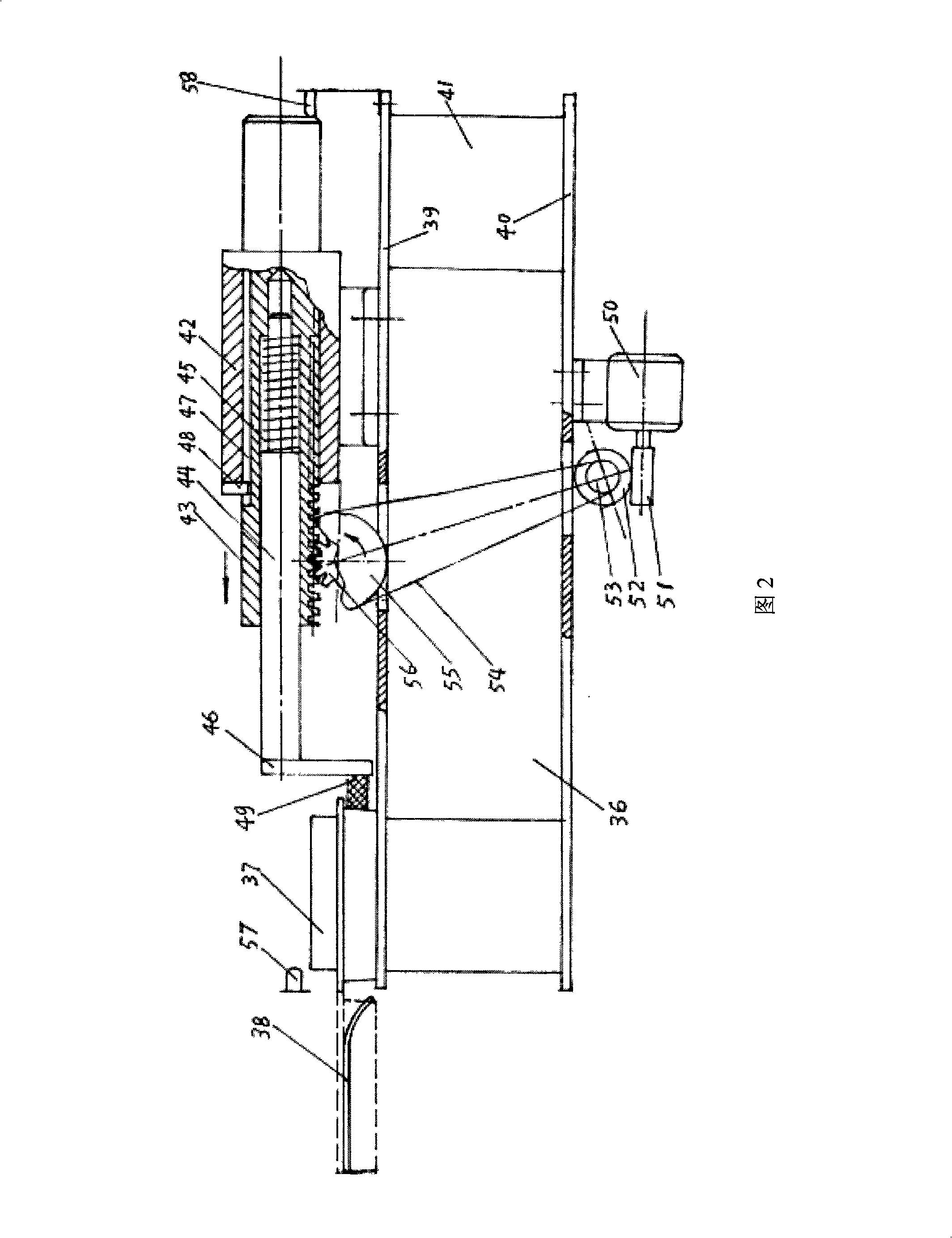

Stator stack thickness detector

InactiveCN101191717AGet rid of manual operationThe test result is accurateMechanical thickness measurementsMachiningPiston rod

The invention belongs to electrician machining equipment, particularly relating to a stator thickness detection device which is used to measure the thickness of the stator iron core for the stator detection mintmark slot combined machine. The invention is characterized in that a faceplate is provided with a base of which one side is provided with a support base, a detection press plate which is arranged below the support base is fixedly connected with a piston rod of a cylinder with readable range which is arranged on the upper end face of the support base; the detection press plate is provided with a guide rod arranged in a guide sleeve on the upper end face of the support base. The invention has the advantages of accurate detection result and high efficiency.

Owner:王伟修

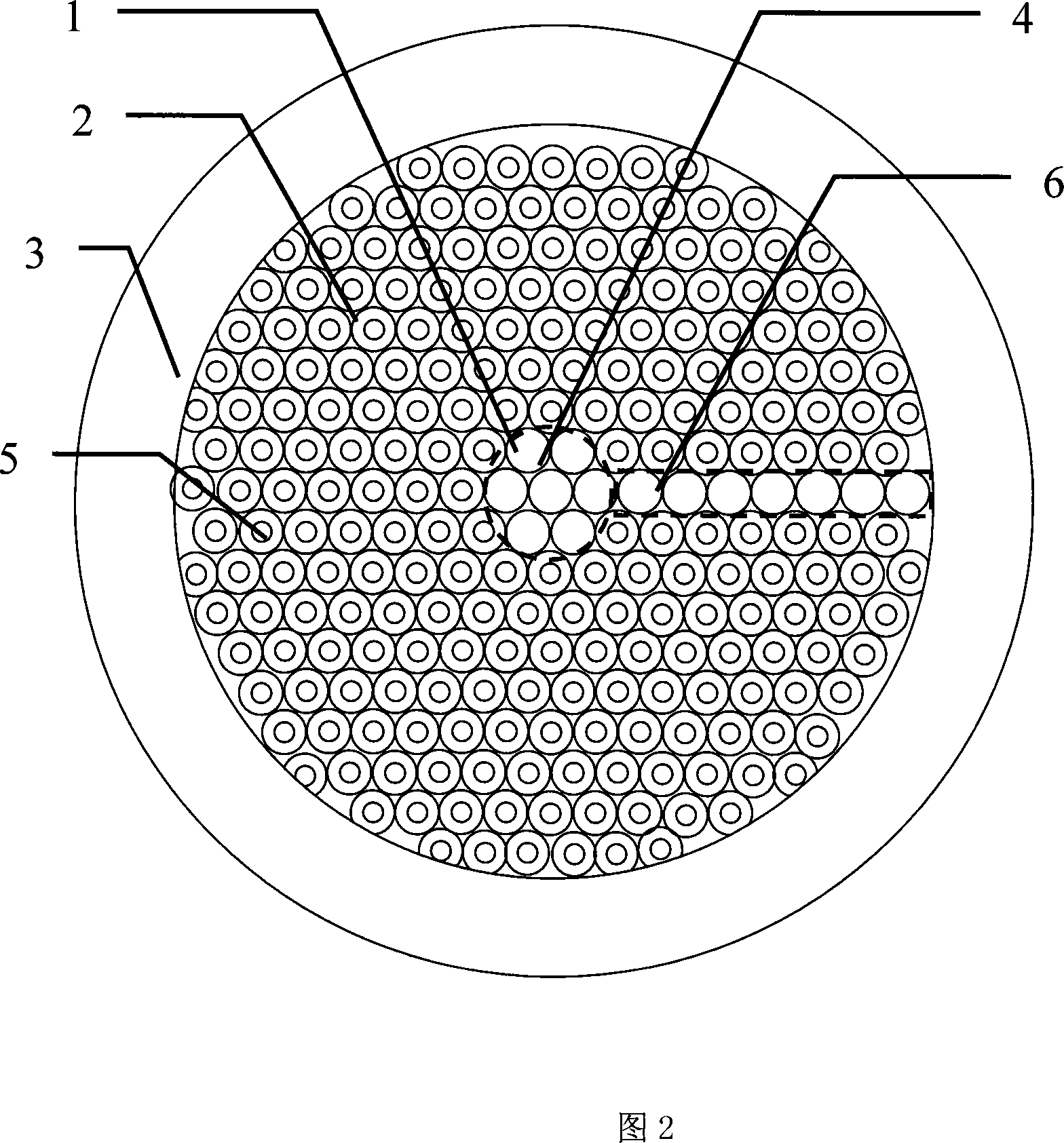

Side leaking photon crystal optical fiber and producing method thereof

InactiveCN101021591AStrong spatial rotation sensitivitySensitive detection of rotationGlass making apparatusCladded optical fibreRefractive indexEngineering

The invention is a side leakage photon crystal optical fiber, and its structure has one or two light wave high-equivalent refractivity linear regions extending outward from core region to pass through coating region and being parallel with the fiber core and having cross section height between half wavelength and wavelength of transmitted light, and its preparing method comprises the three steps of material selecting and processing, precast bar making, charging and wire drawing on wire drawing tower; the transmission losses of two vertical polarizing state of its guide mode have obviously difference, and it can use as single polarizing optical fiber itself and because of having stronger rotation sensitivity, it is suitable to small-rotating angle optical fiber sensing, and can be used for making standardized and automated production of high quality optical fiber couplers.

Owner:BEIJING JIAOTONG UNIV

Mycobacterium tuberculosis sputum specimen liquefier kit and application thereof

InactiveCN103555809AReduce dosageEliminate the centrifugation stepMicrobiological testing/measurementPreparing sample for investigationAcid-fastMedicine

The invention belongs to the technical field of detection of medical samples, and in particular relates to a mycobacterium tuberculosis sputum specimen liquefier kit and application thereof. The mycobacterium tuberculosis sputum specimen liquefier kit includes a liquefier R1 and a liquefier R2; and the liquefier R1 is ammonia, and the liquefier R2 is a water solution of a sulfydryl reducing agent. The invention also provides application of the above mycobacterium tuberculosis sputum specimen liquefier kit, and the kit can be applied to acid-fast staining microscopic examination of mycobacterium tuberculosis and liquefaction of sputum specimen before isolated culture. Compared with the prior art, the technical scheme provided by the invention has the following advantages: the kit helps to improve smear quality, increases positive detection rate and reading efficiency, optimizes the existing pretreatment technology for sputum specimens, satisfies requirements of multiple detection samples, and is in favor of staining microscopic examination of the sputum specimen smear and automation operation of isolated culture and inoculation.

Owner:SHANGHAI WEIYIN BIOTECH CO LTD

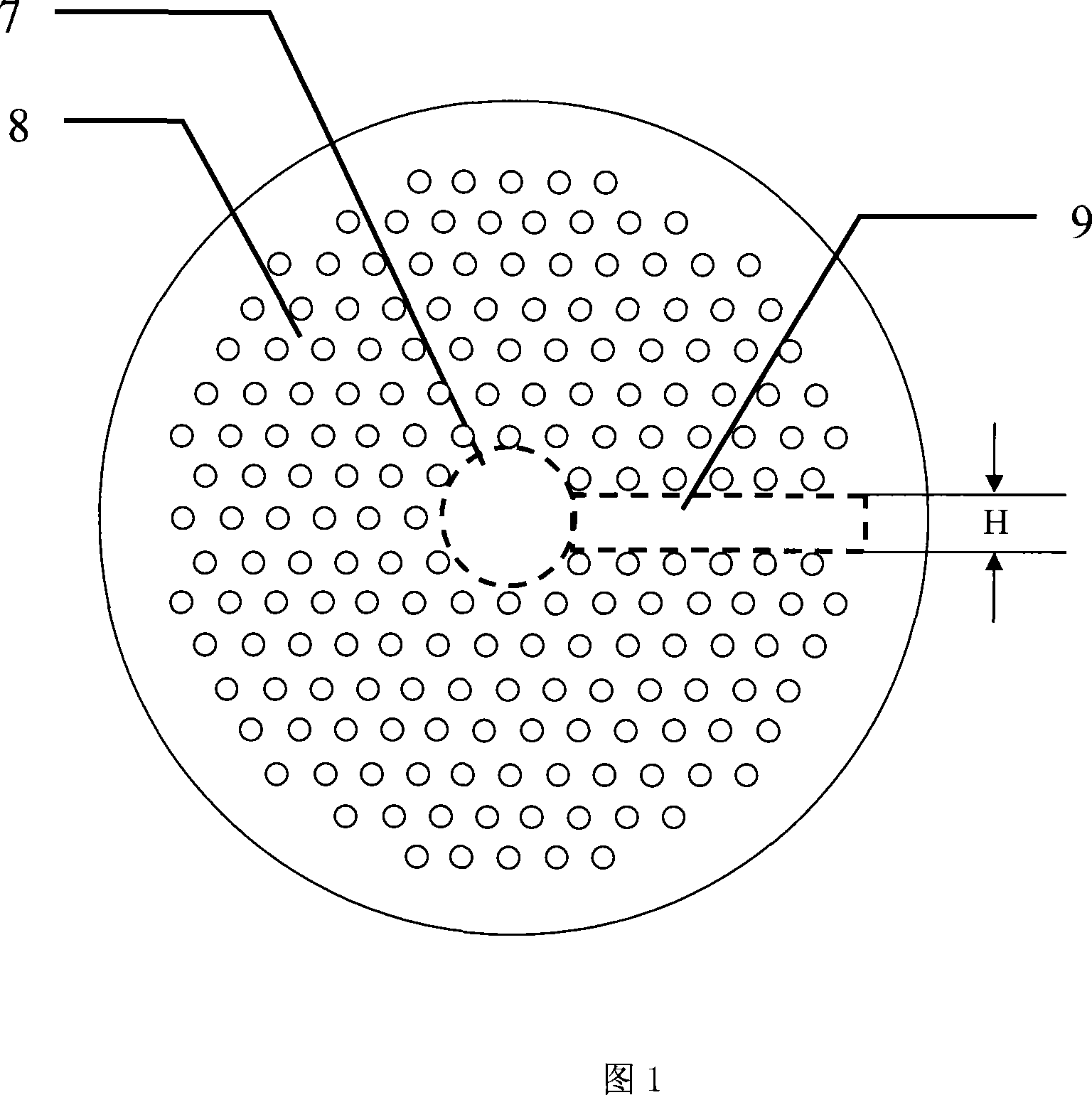

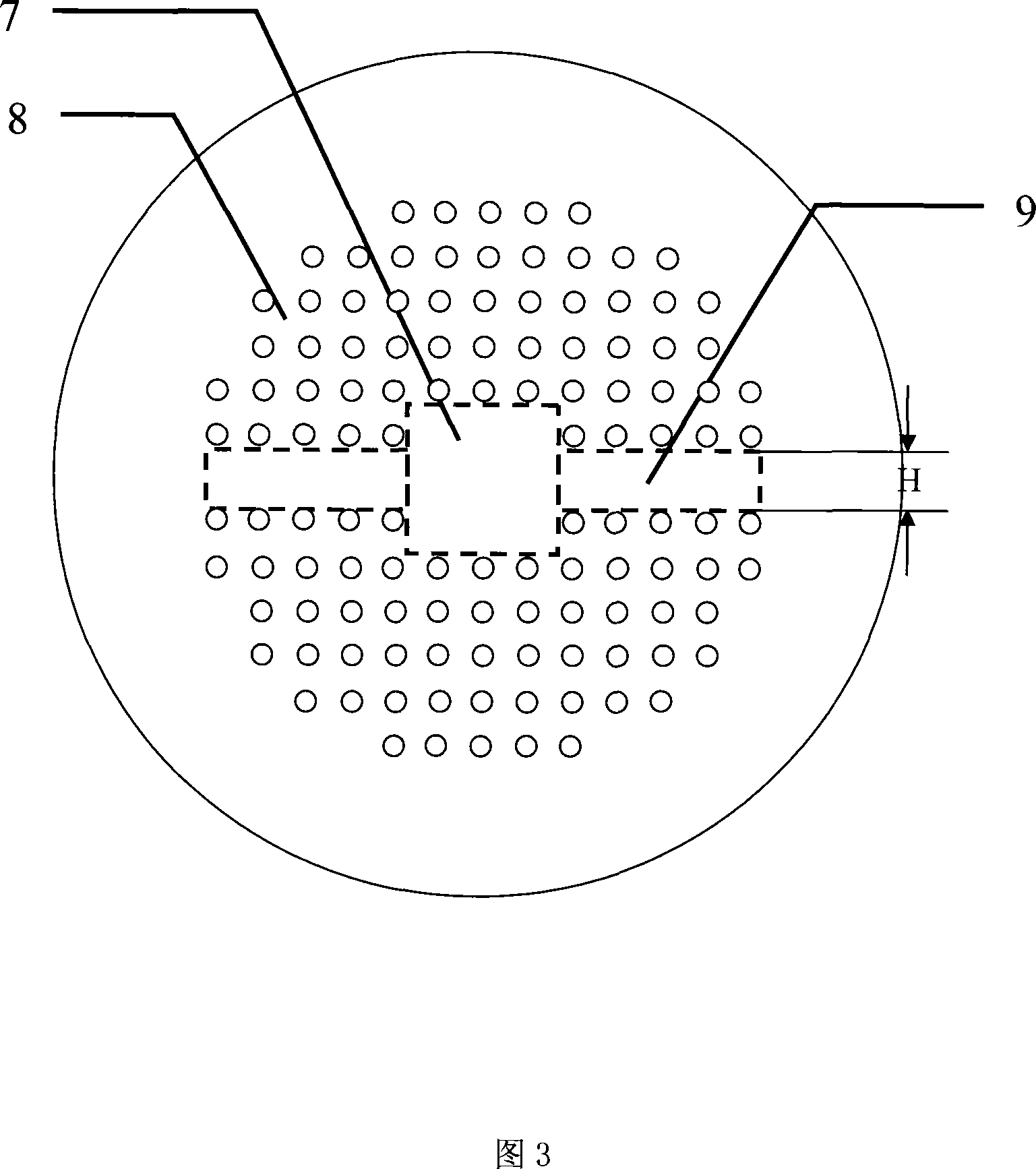

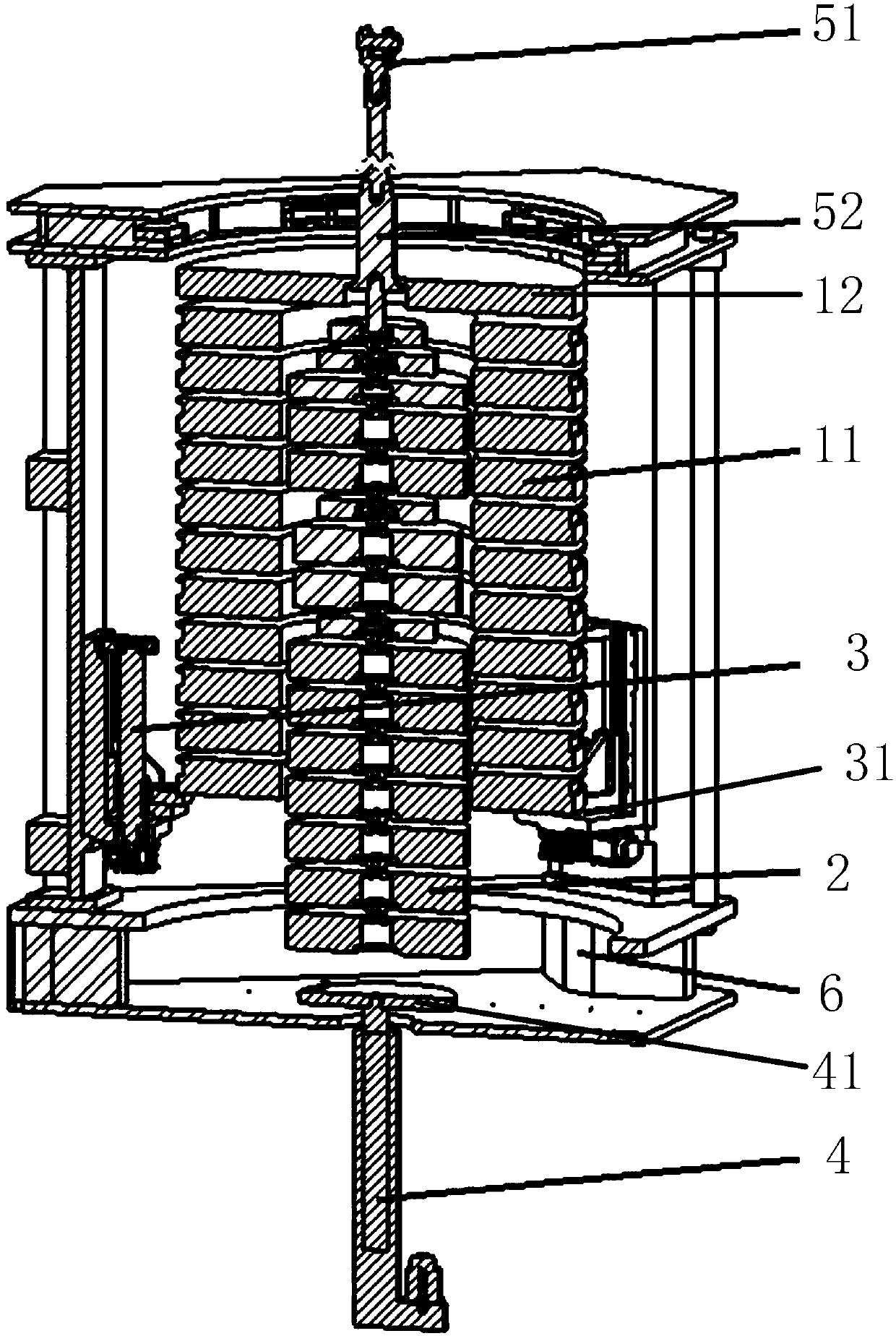

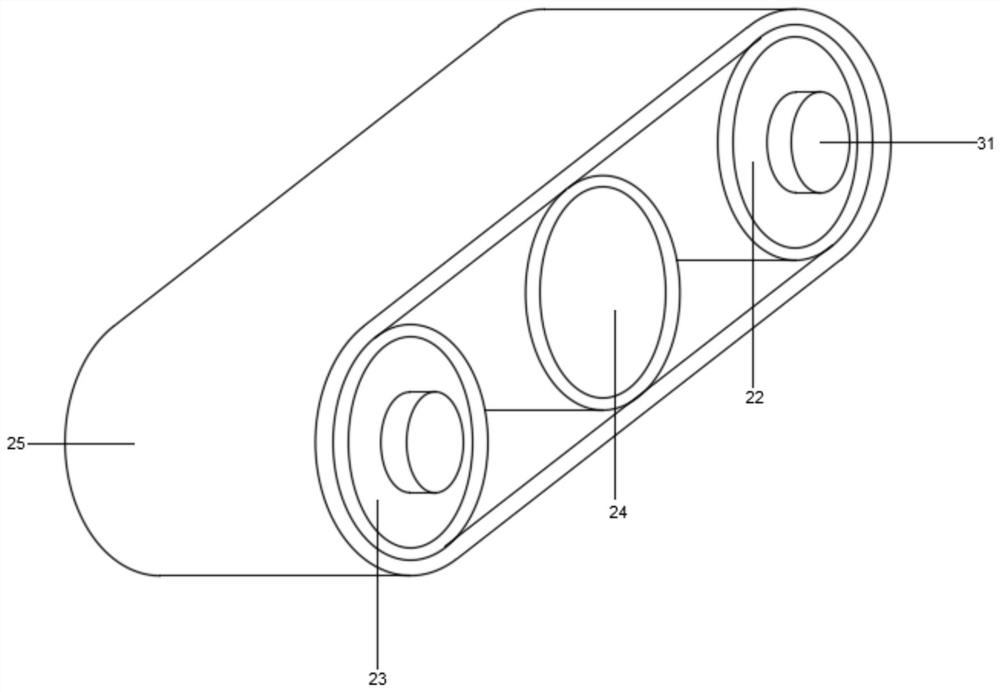

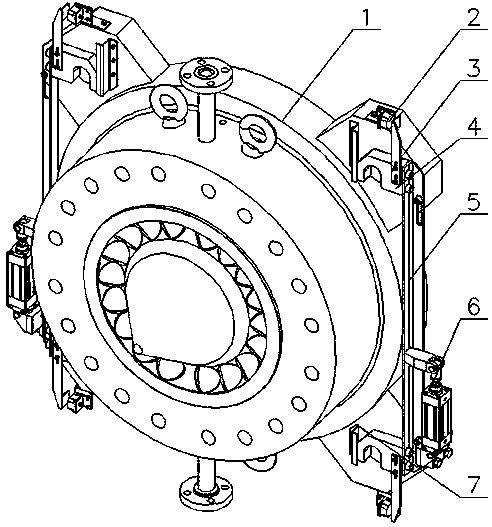

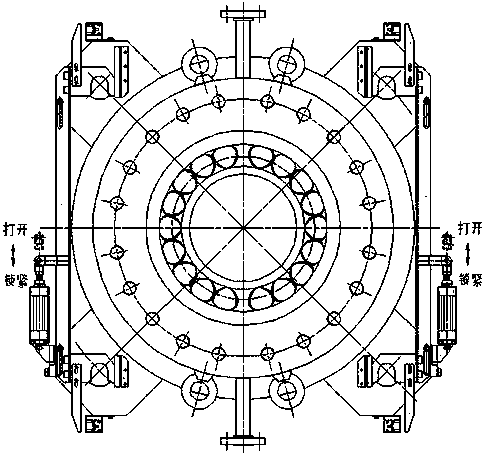

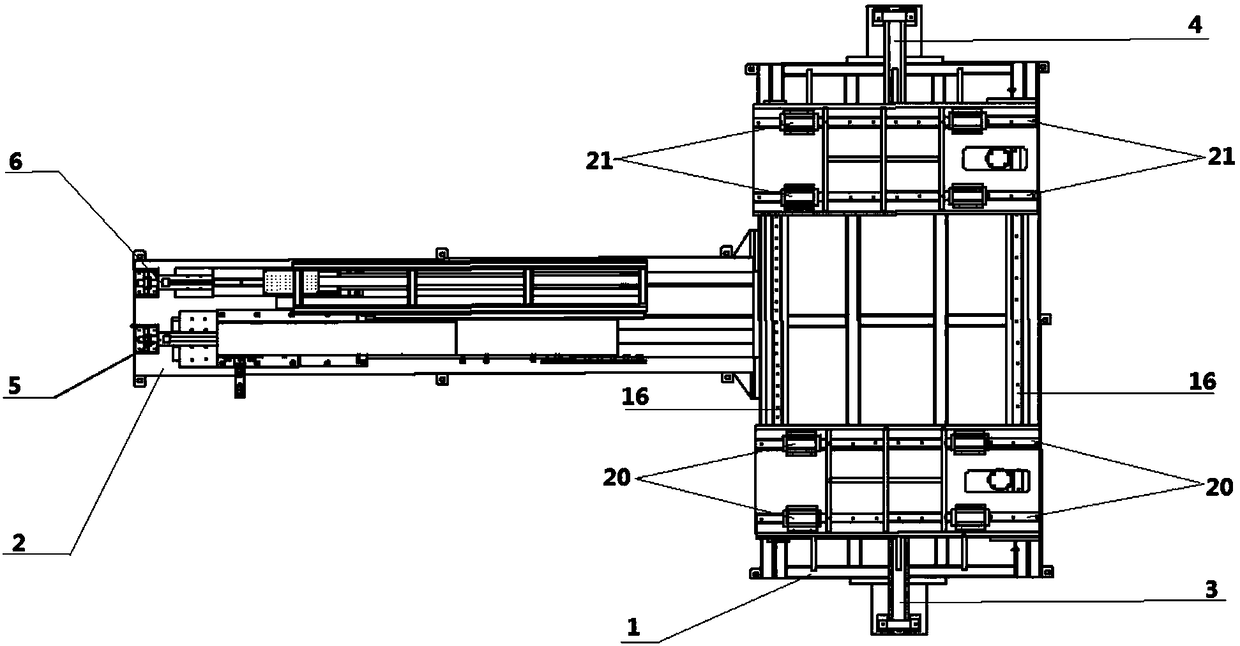

Nested type electronic hoist scale weight loading system

ActiveCN108020312AGet rid of tedious manual operationGet rid of manual operationWeighing apparatus testing/calibrationEngineeringScale weight

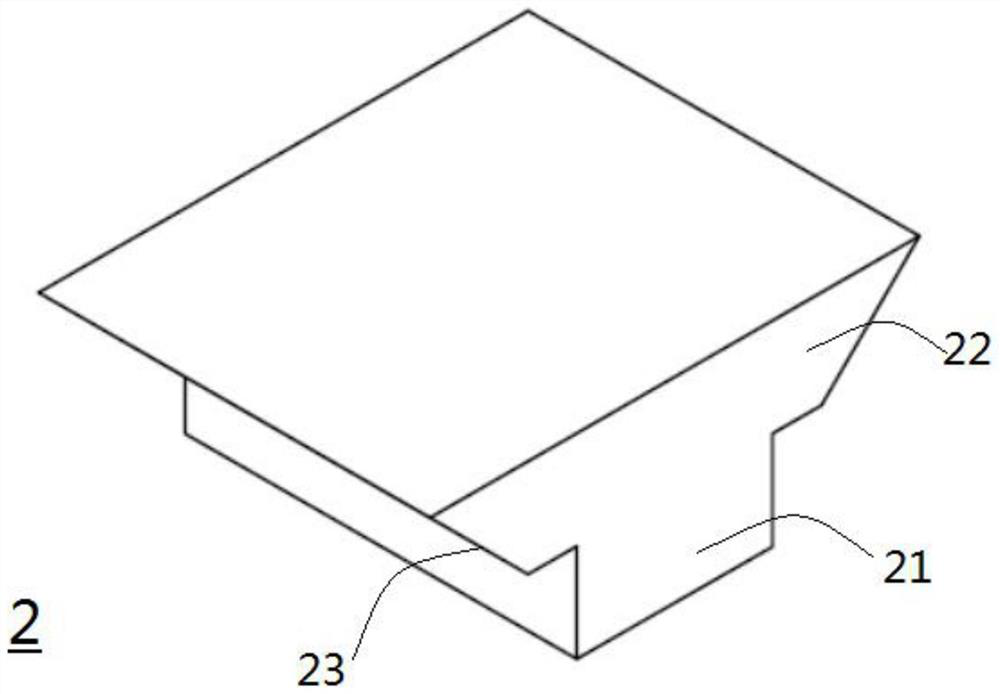

The invention discloses a nested type electronic hoist scale counterweight loading system comprising an outer ring weight group, an inner ring weight group, an outer ring weight driving mechanism andan inner ring weight driving mechanism; the inner and outer ring weight groups are made to order according to electronic scale detection requirements, up and down displacement of the weight groups iscontrolled via an electric motor so as to realize electronic hoist scale weight loading effects, complex manual operation of a traditional loading mode is not needed, and security and work efficiencycan be ensured. The inner and outer ring weight groups are adopted at the same time; compared with a traditional single weight group mode, the mode of the inner and outer ring weight groups is advantageous in that a large number of weight points are available to choose from, safety can be improved while height of a weight mechanism is reduced properly, and loading work efficiency is improved via synchronous inner and outer ring loading.

Owner:苏州市计量测试研究所

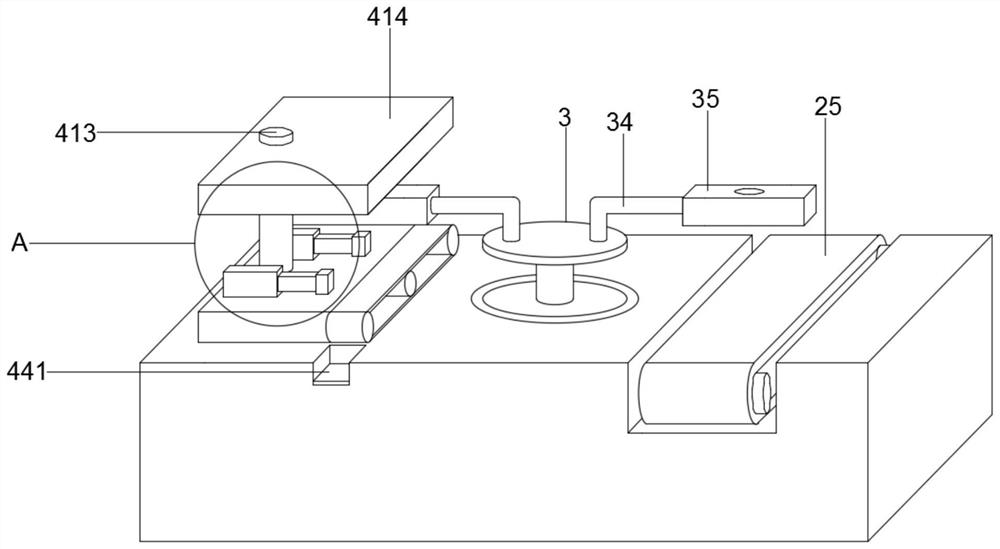

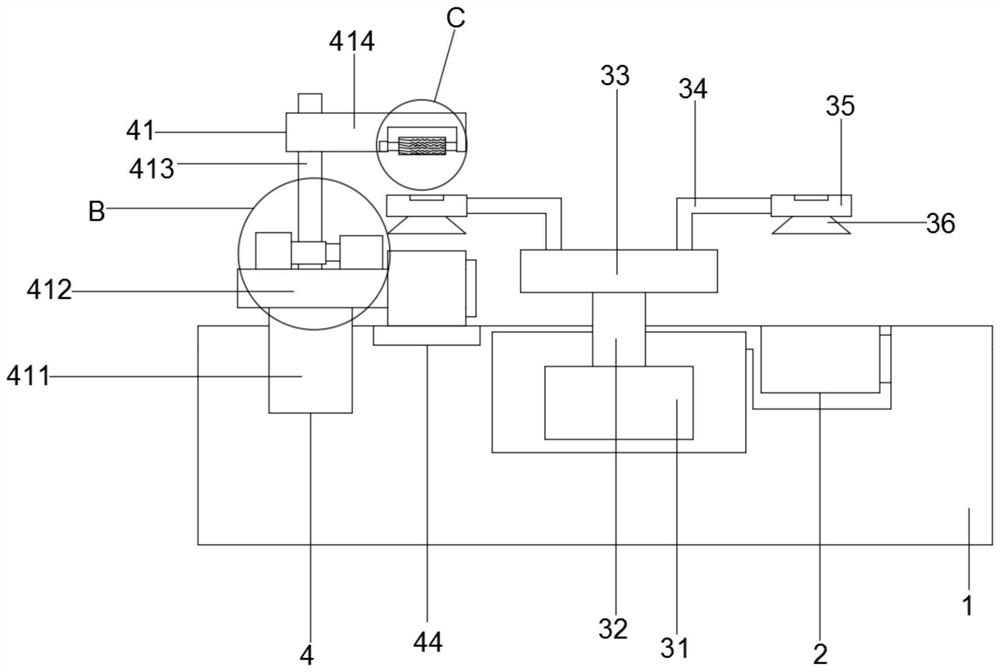

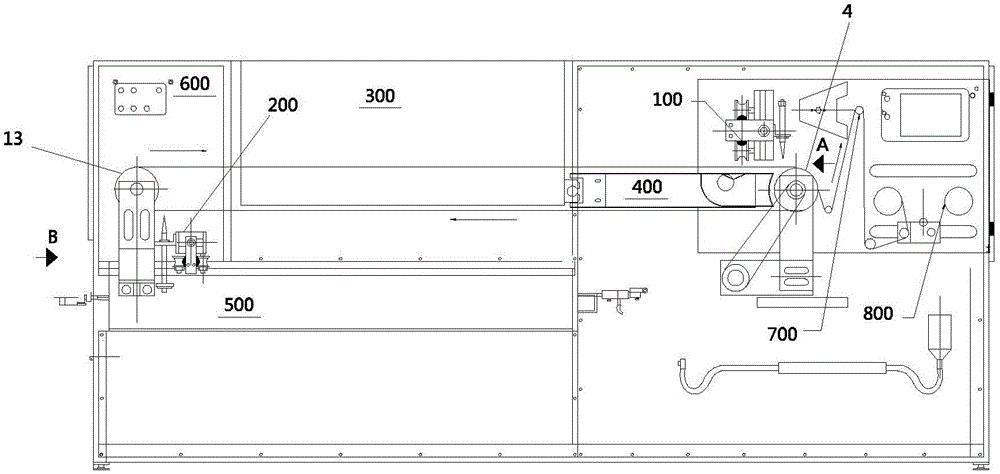

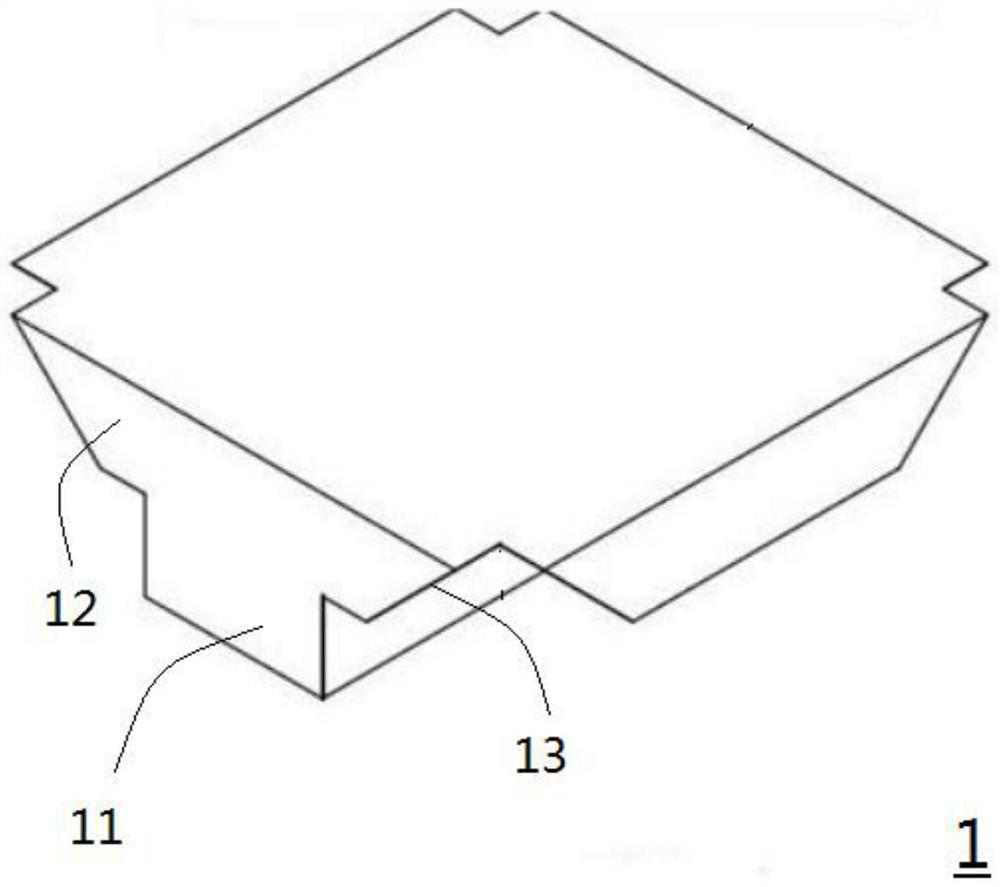

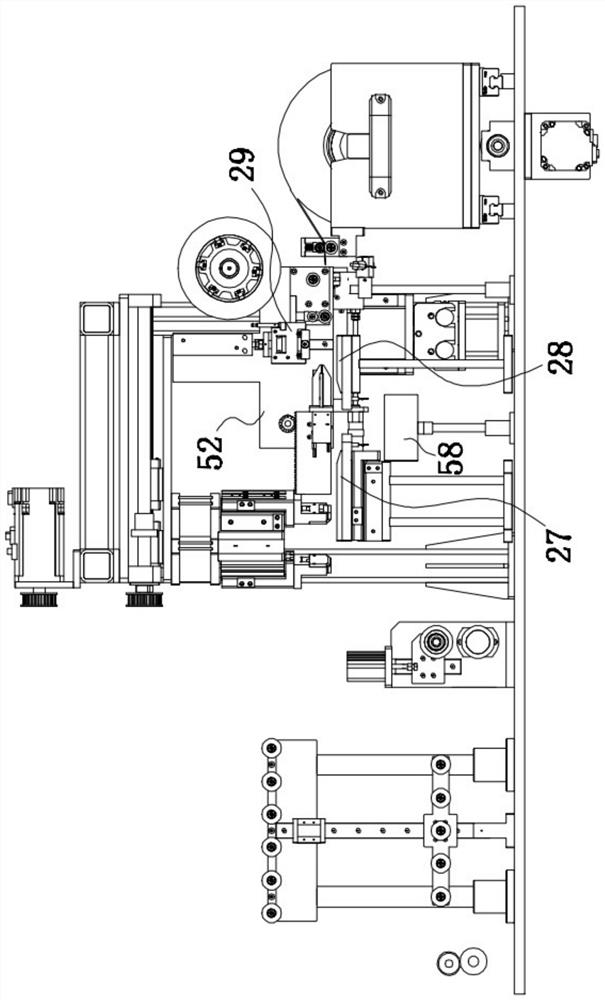

Automatic laminating machine for lithium battery production

PendingCN112670594AExcellent qualityIncrease production speedFinal product manufactureSecondary cellsAutomatic processingProcess engineering

The invention relates to the field of battery production equipment, in particular to an automatic laminating machine for lithium battery production. The laminating machine comprises an equipment base; a conveying mechanism for feeding is arranged at one end of the top of the equipment base, and a raw material carrying mechanism for moving raw materials is arranged in the middle of the top of the equipment base; and the other end of the top of the equipment base is provided with a raw material processing mechanism for processing a pole piece. According to the invention, full-automatic processing of lithium battery laminations is realized through the conveying mechanism, the raw material carrying mechanism and the raw material processing mechanism, and manual operation is completely avoided, so the lithium battery laminations are more efficient and accurate; the correction mechanism is used for correcting and correcting the laminated pieces of the lithium battery after the laminated pieces are laminated, so the difference between a manufacturing method and an individual is smaller when the laminated pieces of the lithium battery are laminated, and the product quality is more excellent.

Owner:湖南久森新能源有限公司

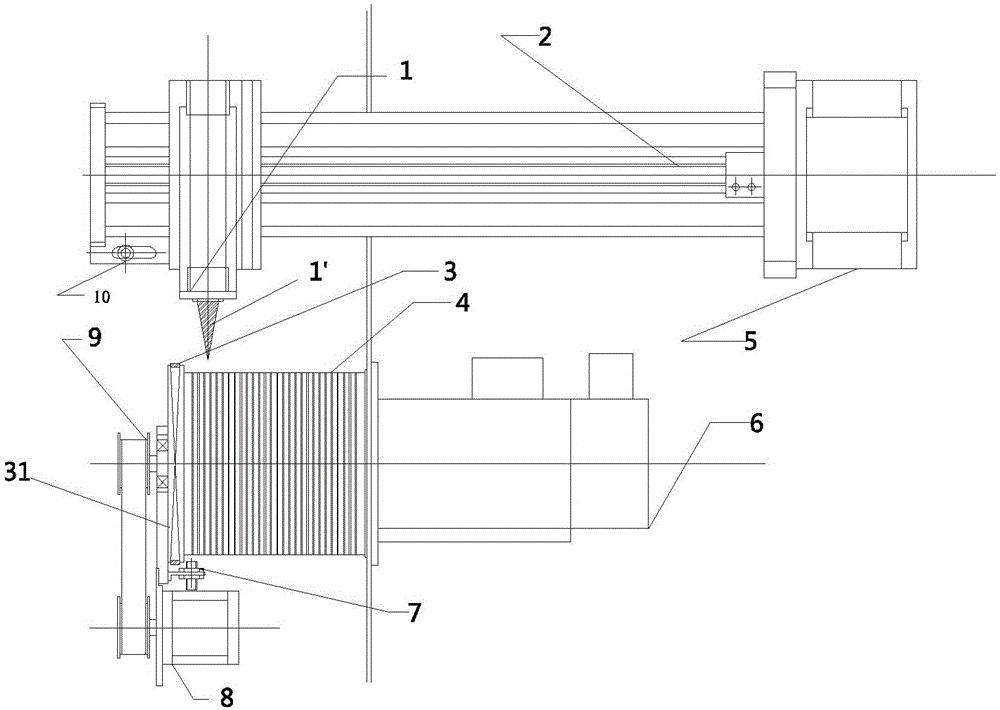

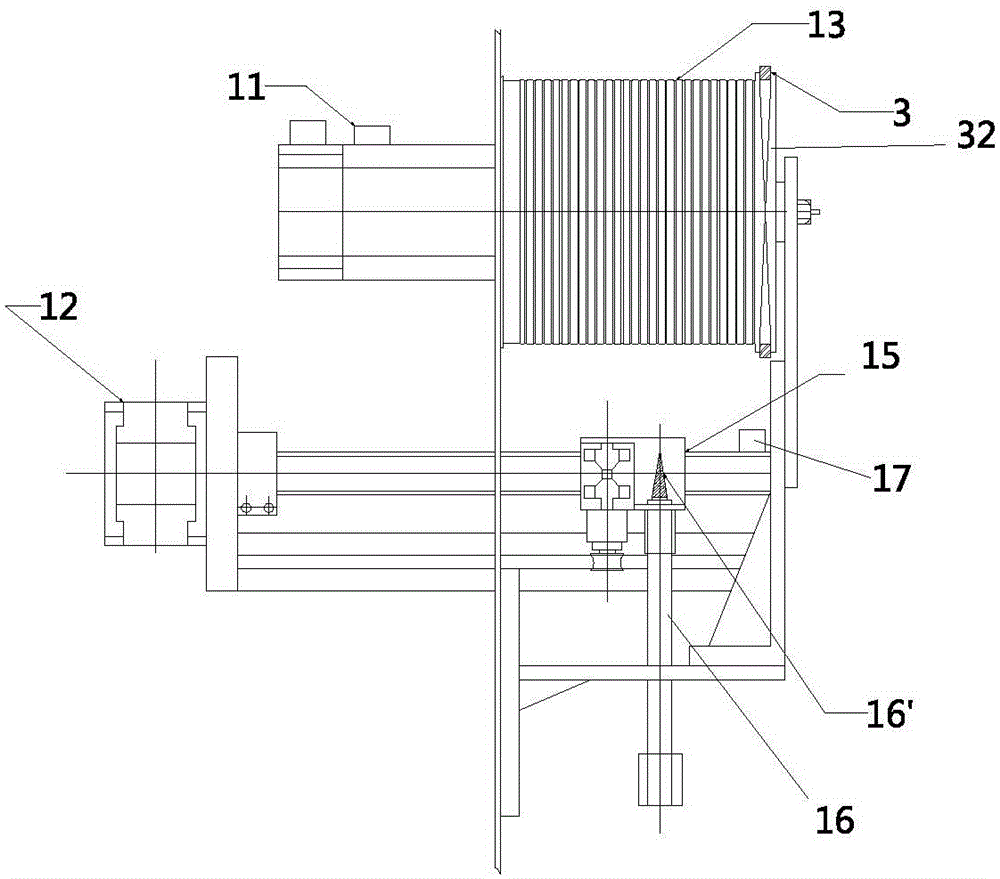

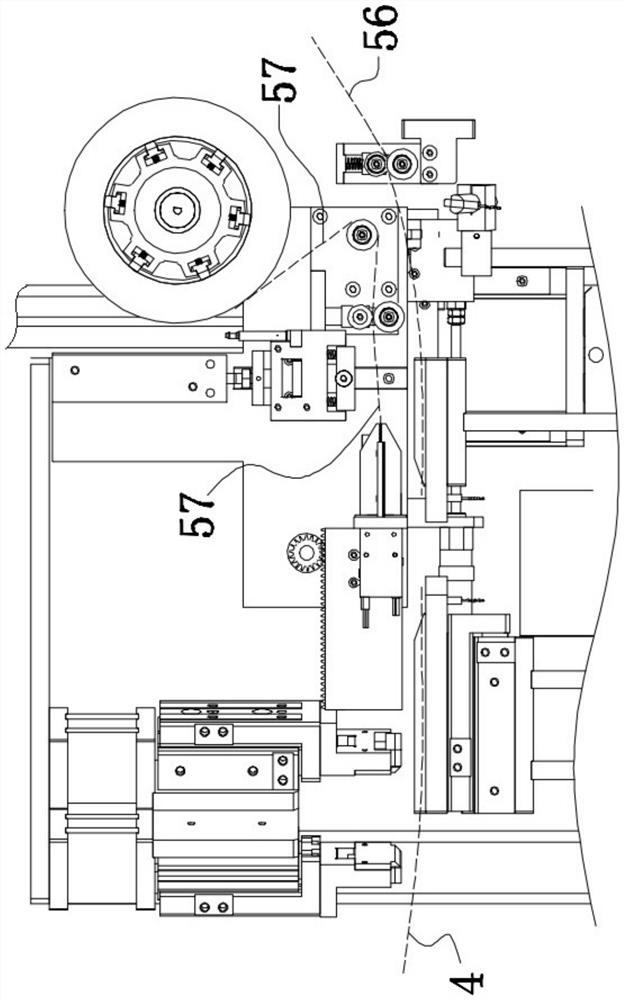

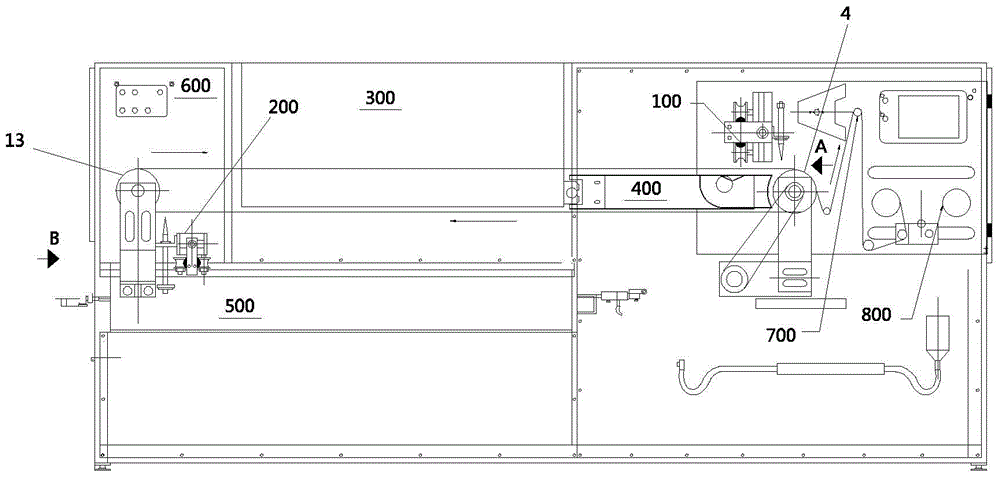

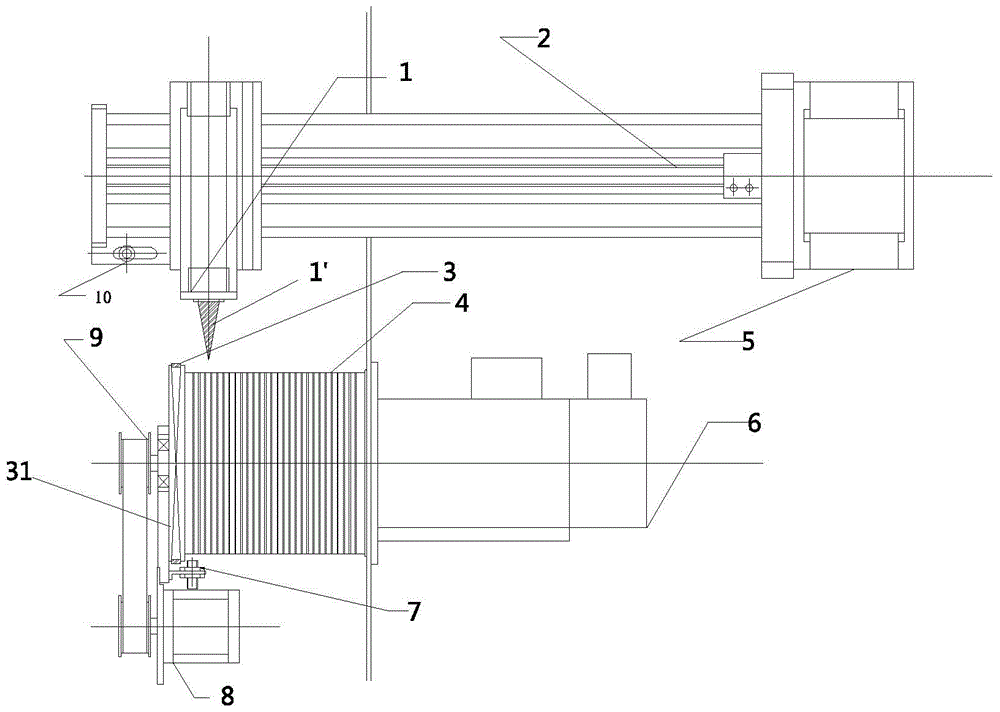

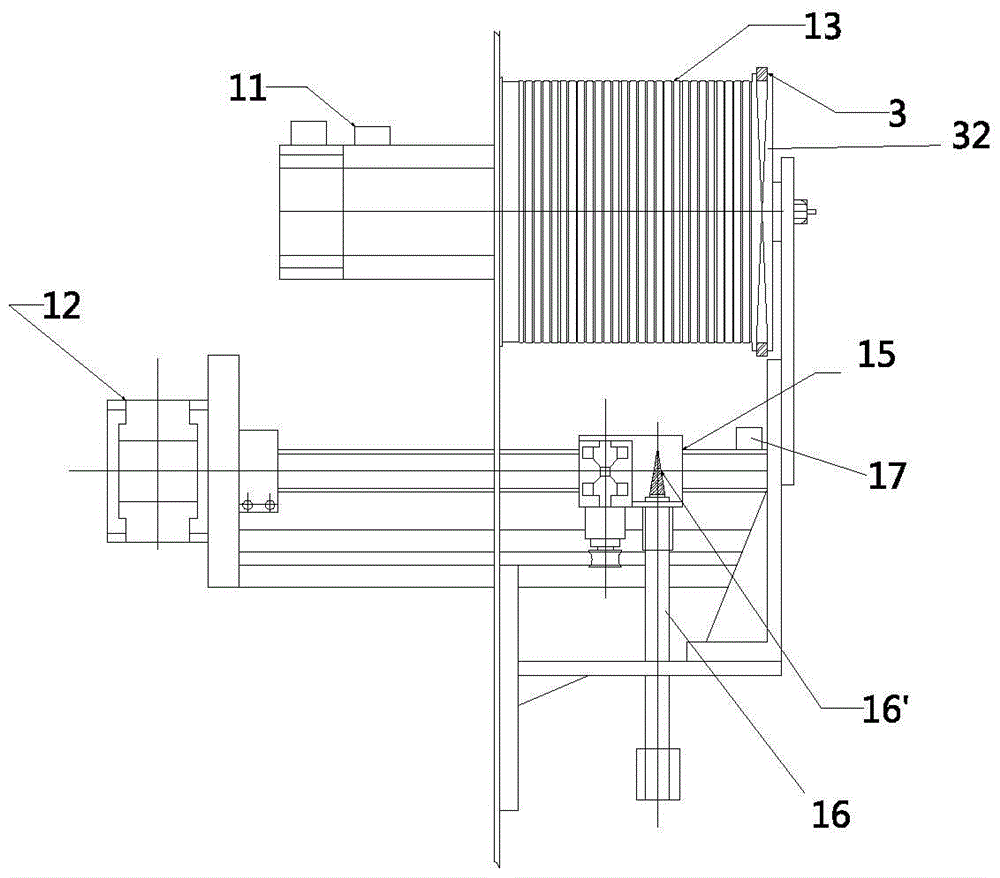

Full-automatic branching system for enamelled wire equipment

ActiveCN105097129ARealize automatic branchingGet rid of manual operationInsulating conductors/cablesEngineeringWire drawing

The invention provides a full-automatic branching system for enamelled wire equipment. The full-automatic branching system comprises an outlet wire feeding roller and a painted part wire feeding roller, wherein a front servo motor is connected with the outlet wire feeding roller and drives the outlet wire feeding roller; a rear servo motor is connected with the painted part wire feeding roller and drives the paint part wire feeding roller; a lead steel strip is wound on a drum which is coaxial with the outlet wire feeding roller and a drum which is coaxial with the painted part wire feeding roller; a steel strip running motor is connected with the lead steel strip and drives the lead steel strip; the full-automatic branching system is characterized in that a front wire drawing head is arranged correspondingly to the outlet wire feeding roller, and is fixedly arranged at the tail end of a cylinder rod of a front wire drawing cylinder; the front wire drawing cylinder is matched with a screw nut to be connected on a left-and-right wire drawing front screw rod; and a front left-and-right operation motor is connected with the left-and-right wire drawing front screw rod and drives the left-and-right wire drawing front screw rod. The full-automatic branching system is provided with a front wire drawing system and a rear wire drawing system; branching actions of the wire drawing heads are reached through coordination of the cylinder and the nut screw, so that automatic branching is realized; the manual branching operation is casted off; and the work efficiency is improved.

Owner:常州市清和机械设备有限公司

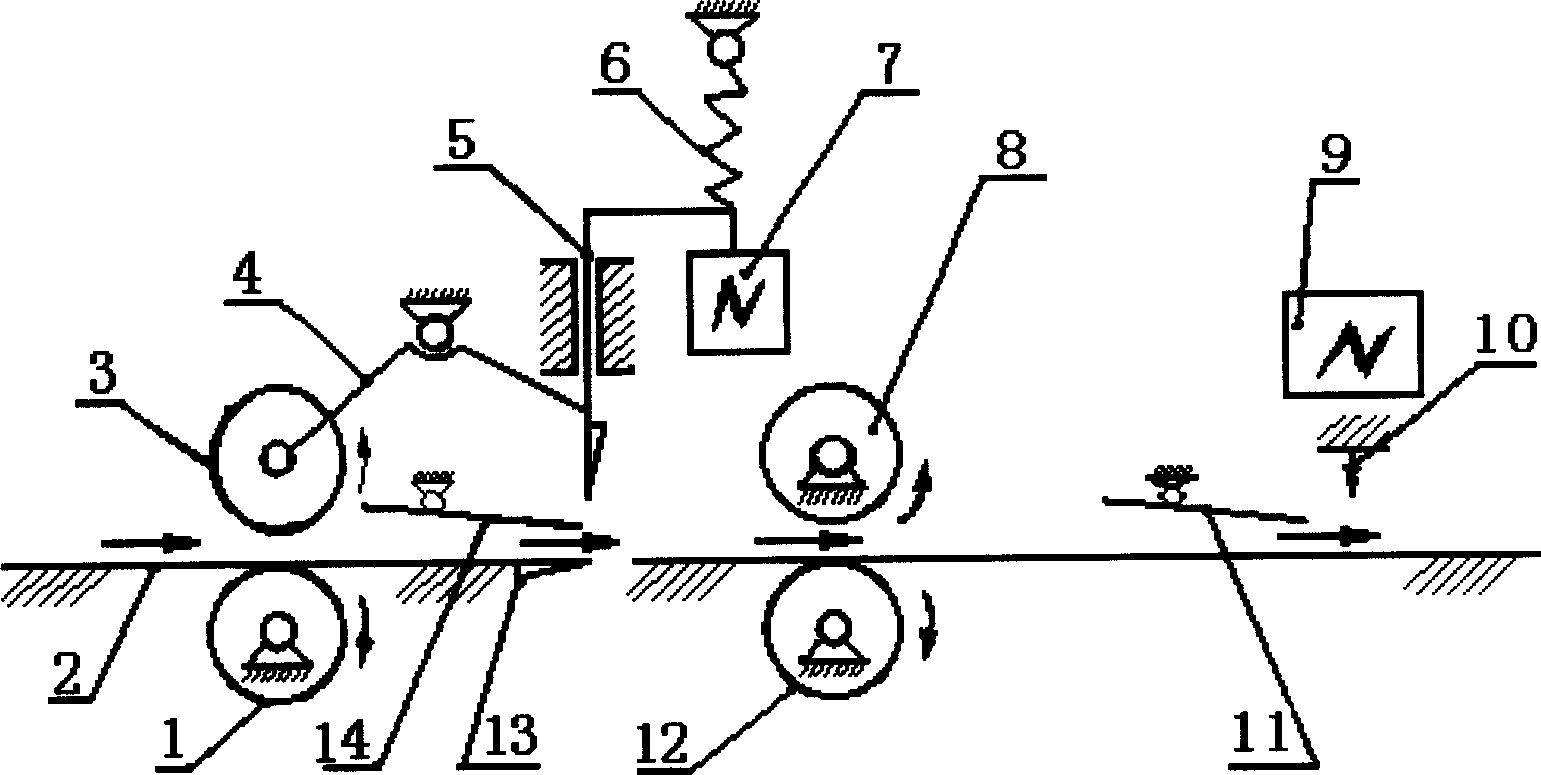

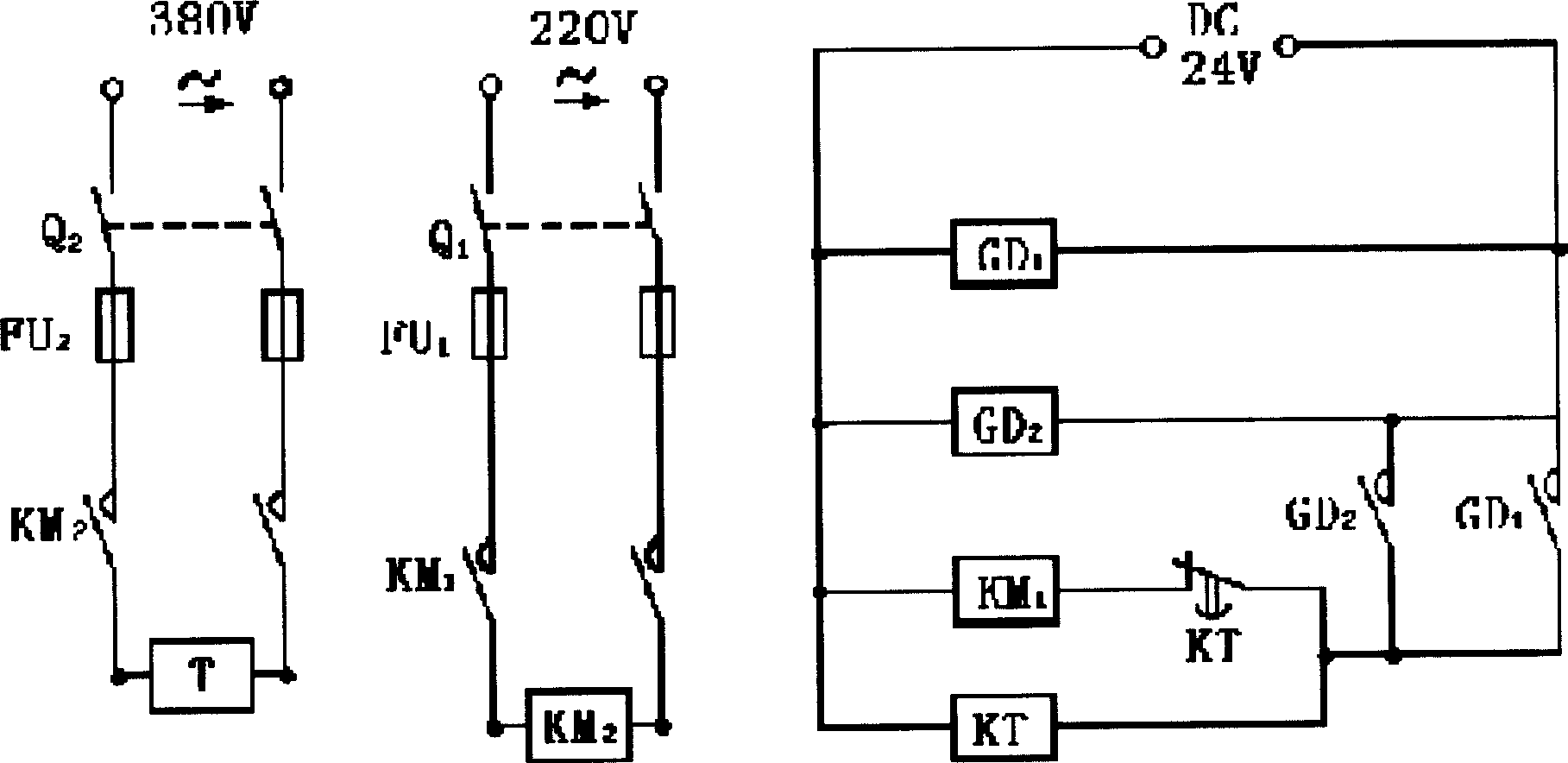

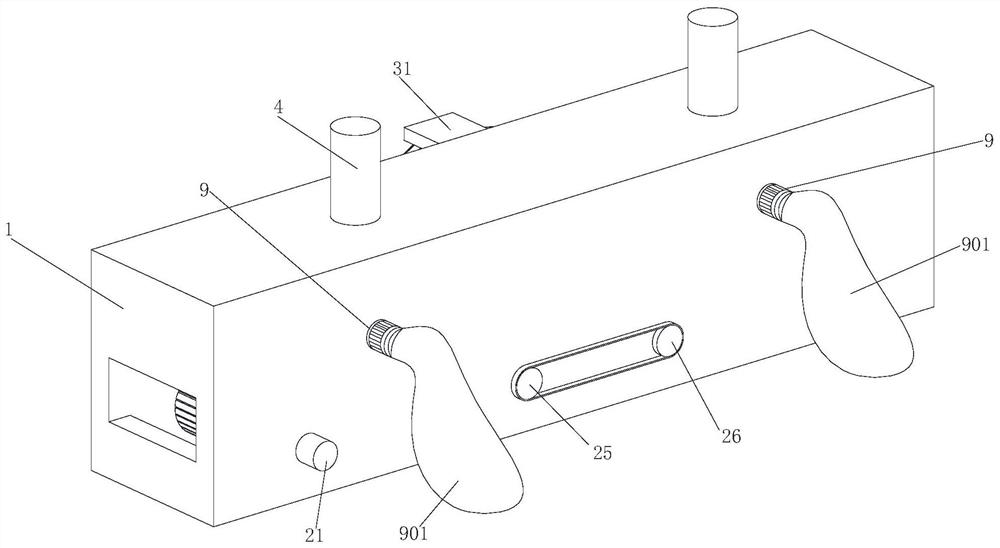

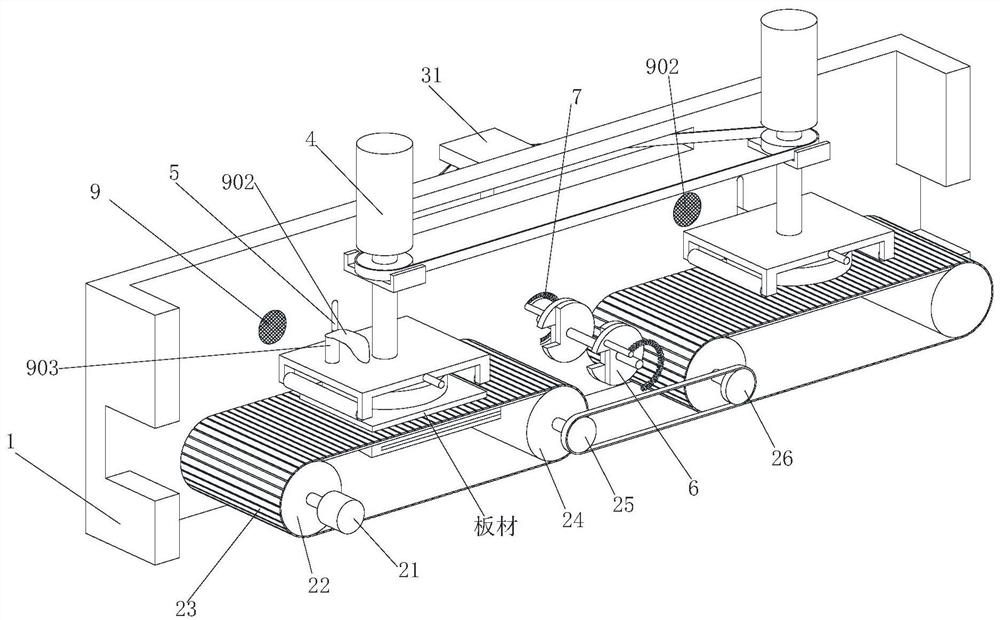

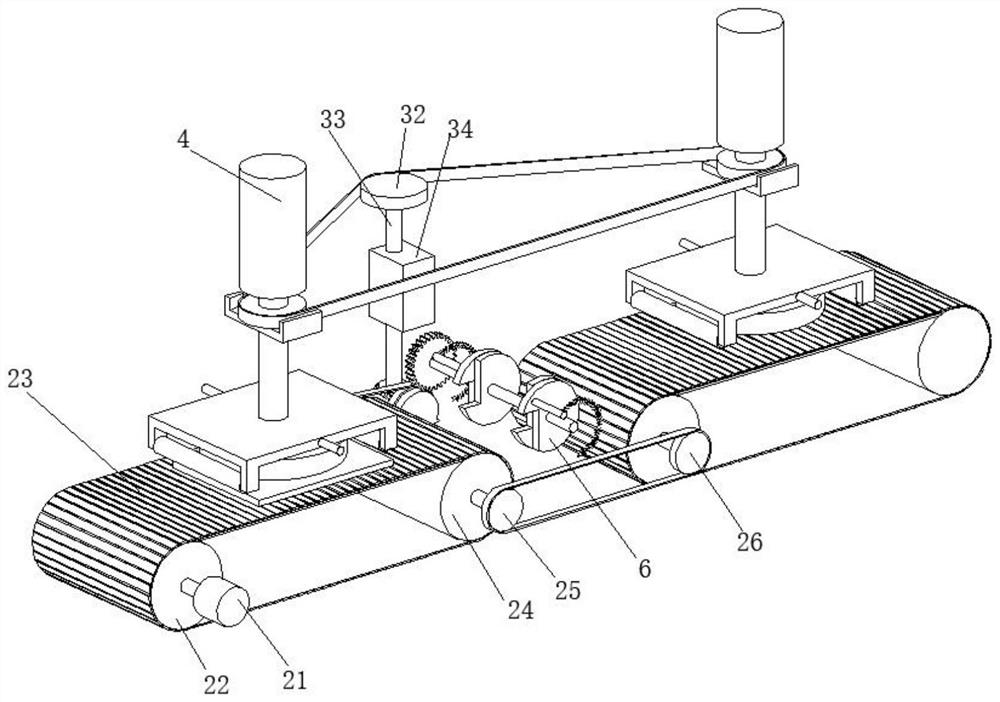

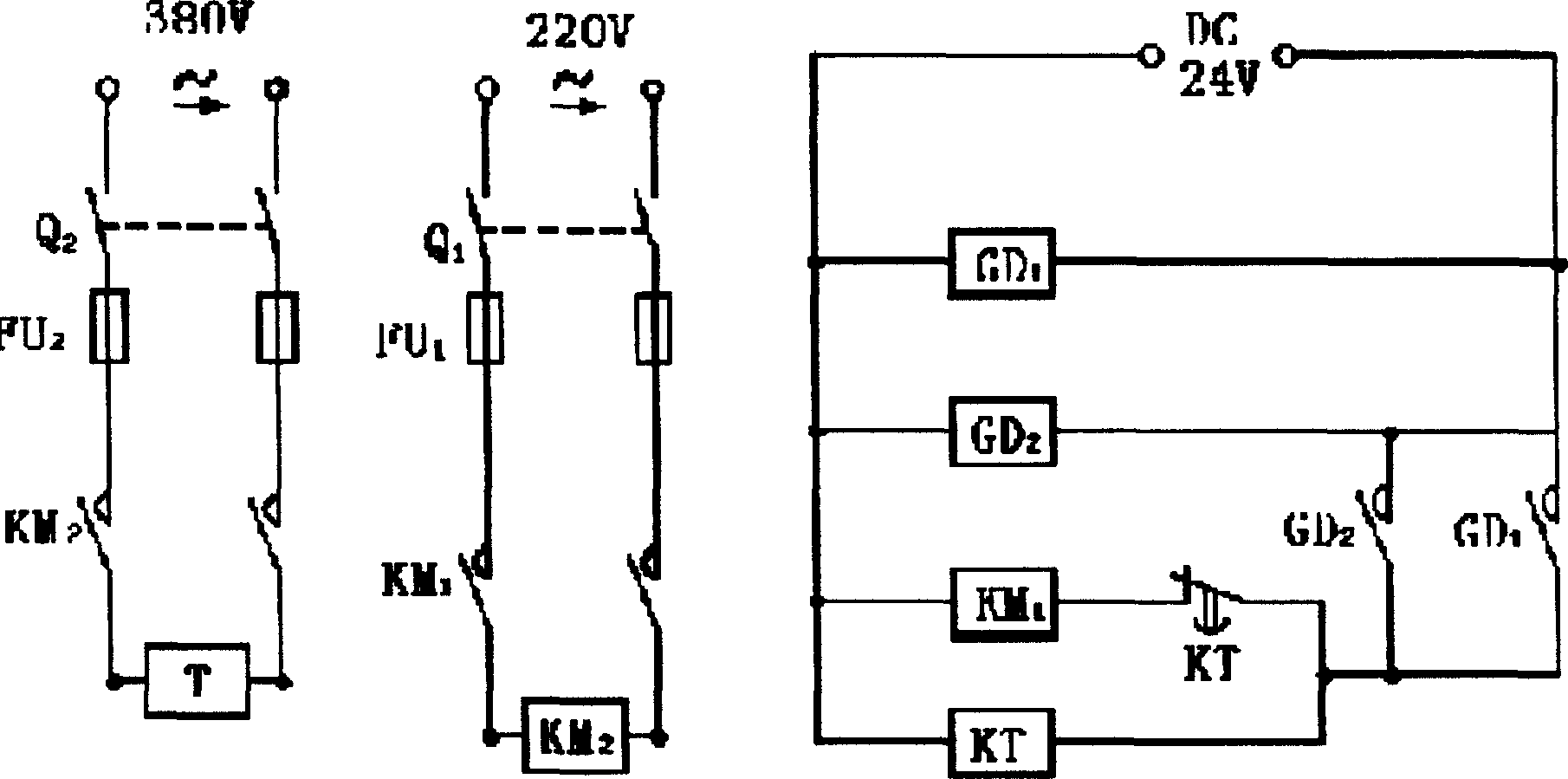

Flexible fixed length automatic disconnecting device for sheet material

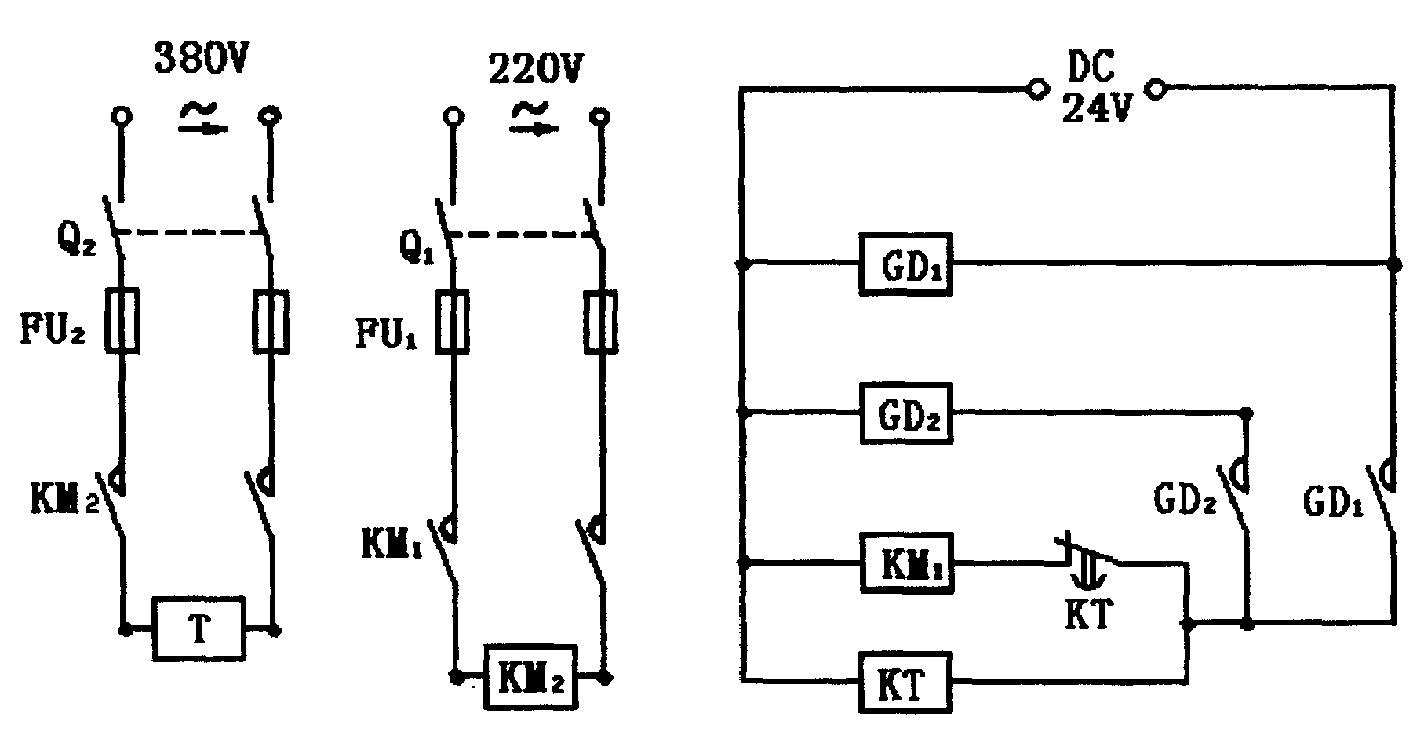

InactiveCN1565816AEasy to adjustEasy to cut to lengthVeneer manufactureElectrical controlElectric control

A sheet flexible length control and automatic cutting device for log rotary cutting production characterized in that it comprises a front guiding mechanism, a pre-pressing mechanism, a cutting mechanism and a rear feeding mechanism and electric control mechanism, wherein the front guiding mechanism, the pre-pressing mechanism, the cutting mechanism and the rear feeding mechanism sequently connect to the sheet moving guide rail on the frame, and the electromagnet movable armature of the electric control mechanism connects to the cutting knife movable blade of the cutting mechanism, photoelectric switch is fixed on the discharge part of the cutting mechanism, the power mechanism connects to the front guiding mechanism and rear feeding mechanism by transmission unit. The invented device can precisely control the sheet length and quickly cut.

Owner:姚运仕 +1

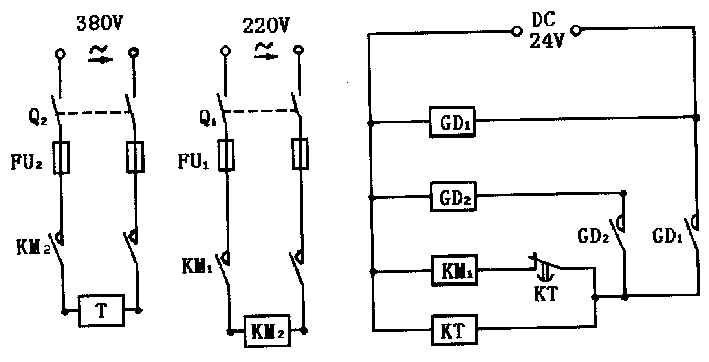

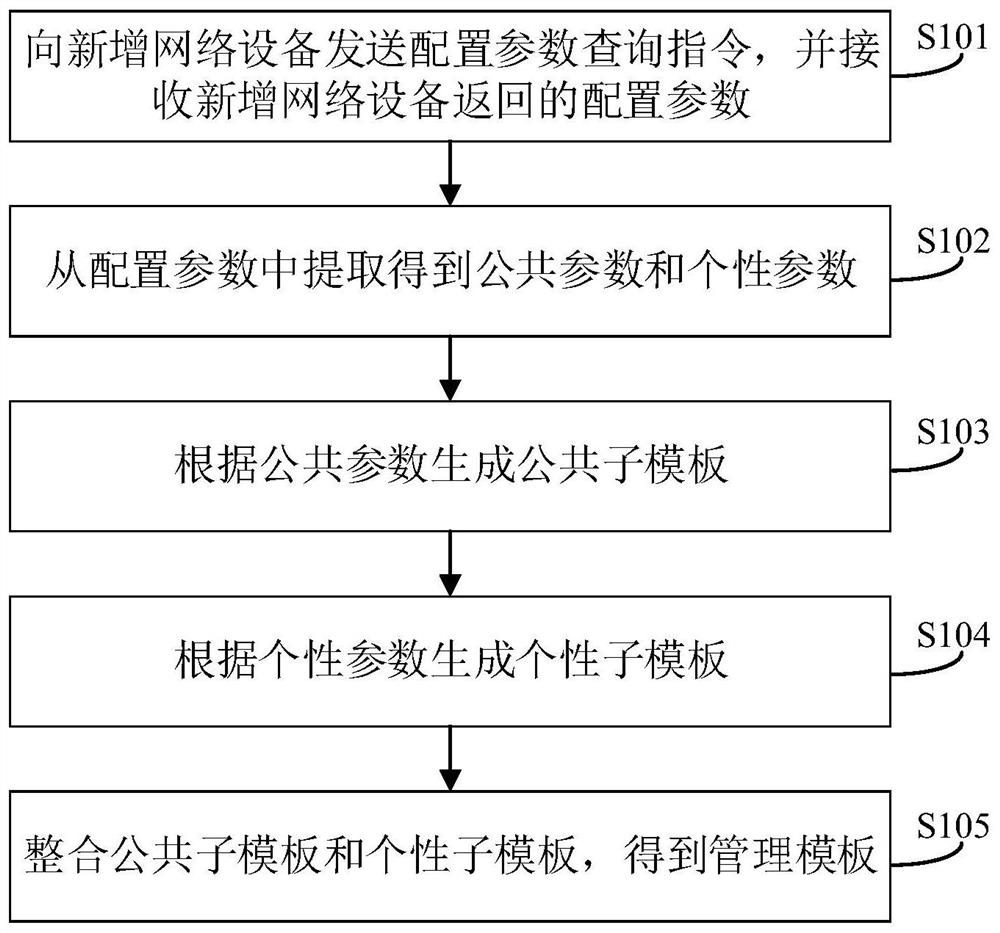

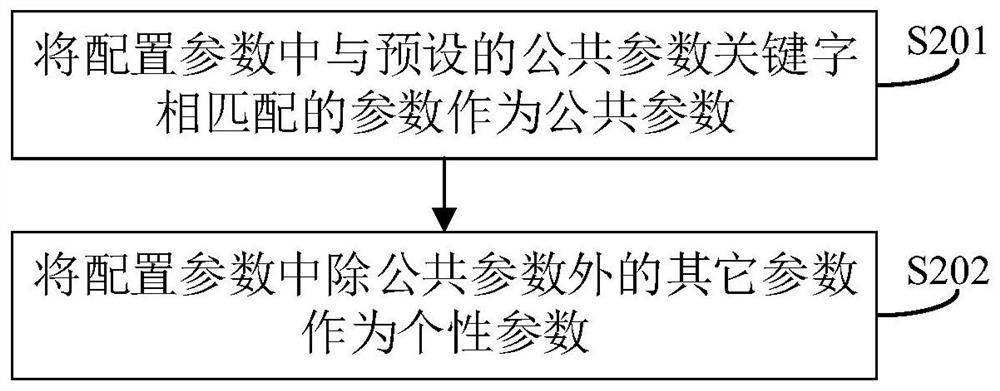

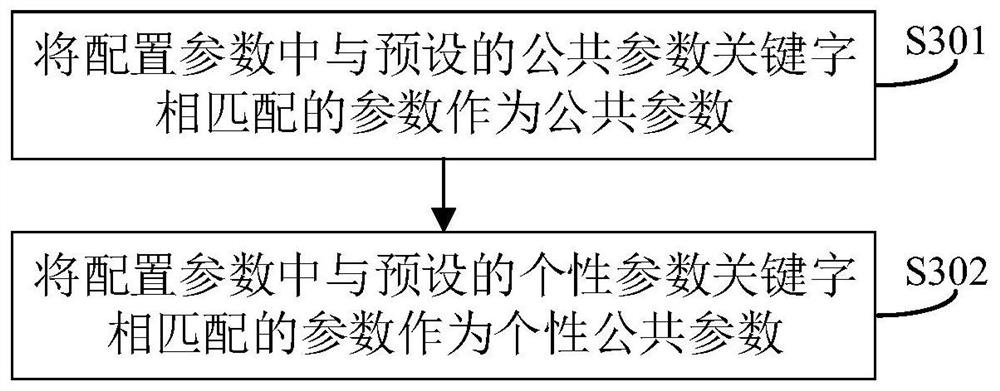

Management template generation method and device, electronic equipment and storage medium

ActiveCN112242909AGet rid of manual operationImprove efficiencyData switching networksComputer programmingDatabase

The invention discloses a management template generation method which comprises the steps: dividing configuration parameters of newly-added network equipment into two parts: public parameters and personalized parameters (the public parameters are part of parameters, used for achieving the same basic function, in different network equipment); finally, based on the public sub-templates and the personalized sub-templates respectively corresponding to the public parameters and the personalized parameters, integrating to obtain a management template of the current network equipment. Although different network devices are produced and provided by different manufacturers according to different standards, the parts, used for achieving the same basic function, in the parameters of the network devices provided by the different manufacturers are still consistent. Therefore, the scheme provided on the basis of the implementation principle can be automatically executed by means of computer programming, manual operation is avoided to a large extent, the efficiency is higher, and the error rate and the cost are lower. The invention furthermore discloses a management template generation device, electronic equipment and a computer readable storage medium, which have the above beneficial effects.

Owner:SANGFOR TECH INC

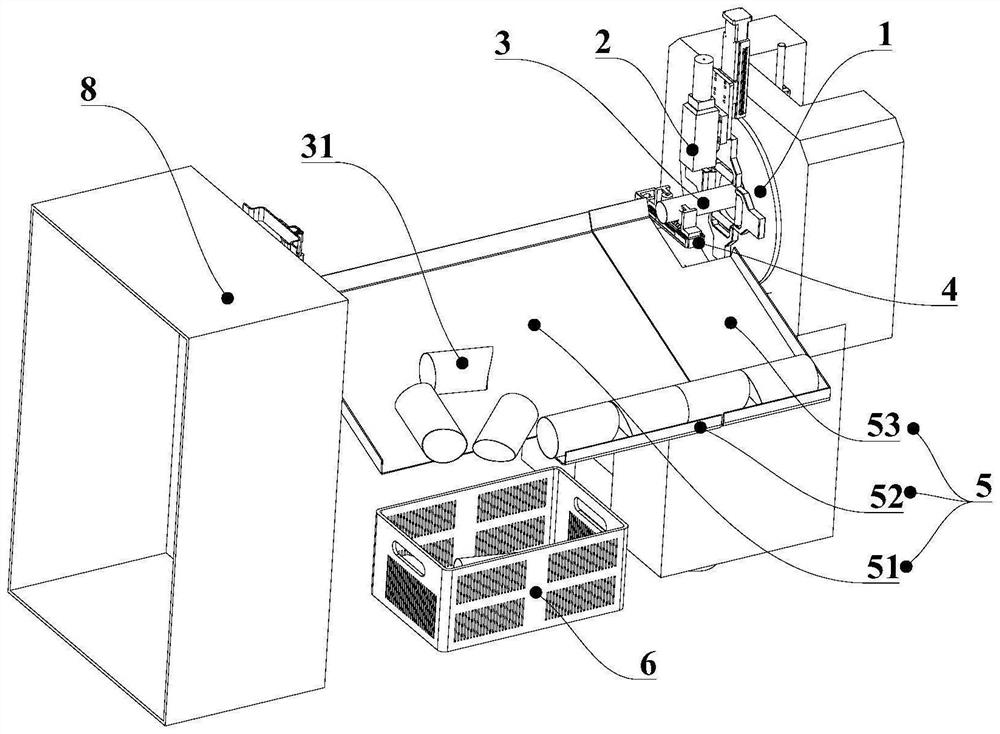

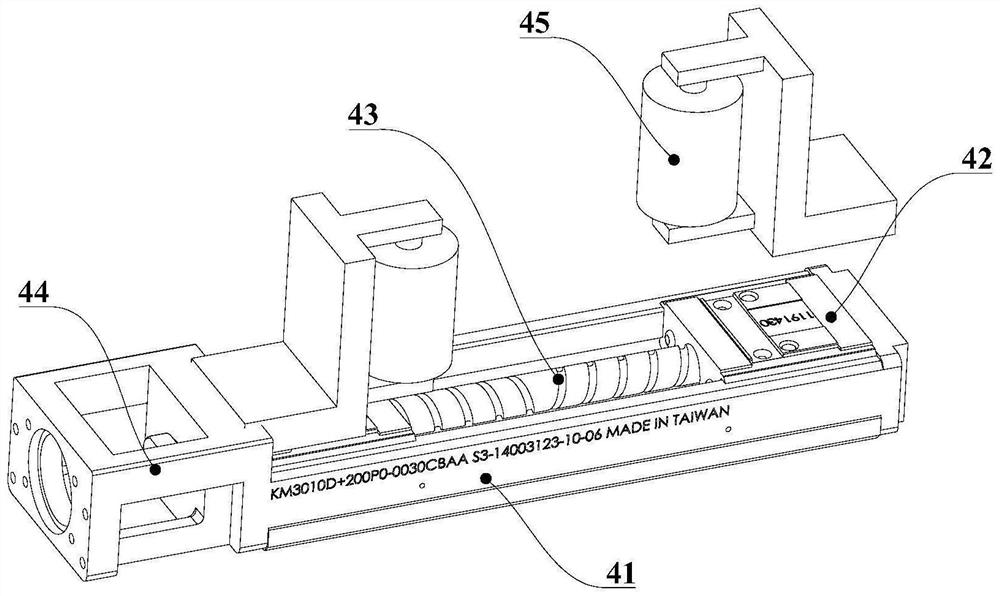

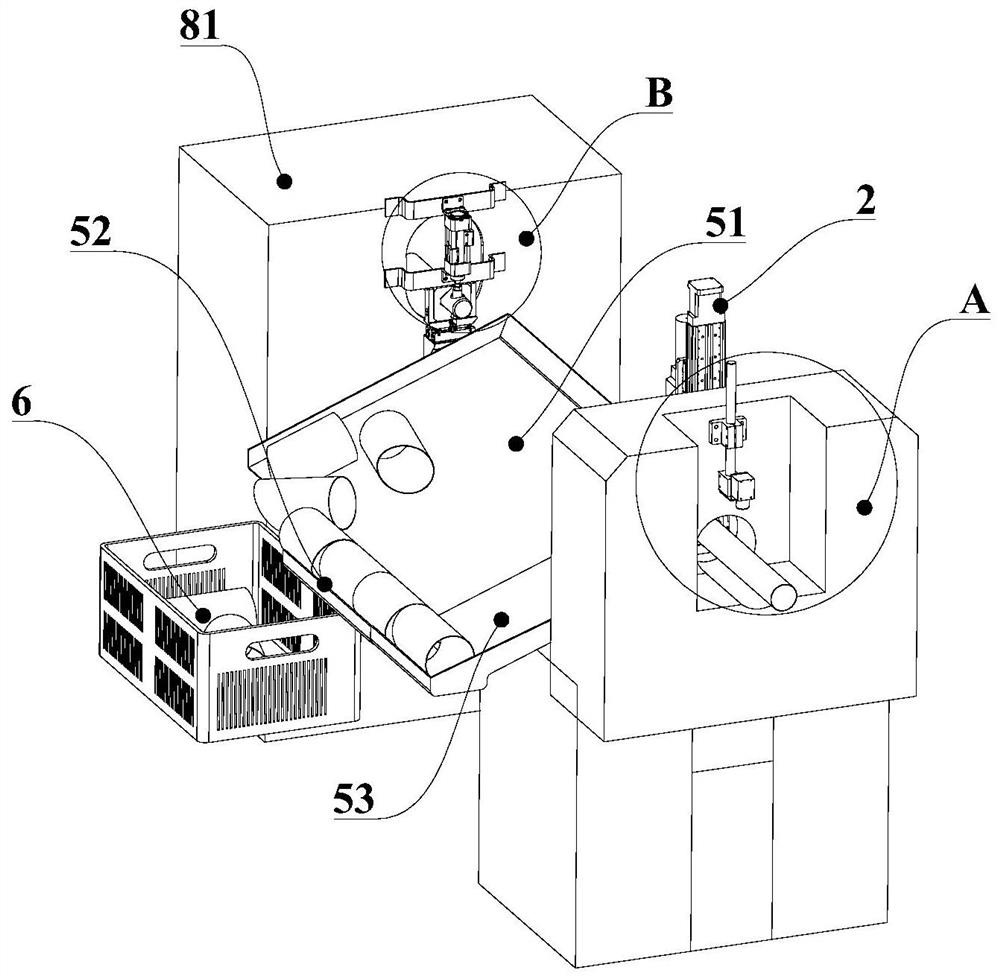

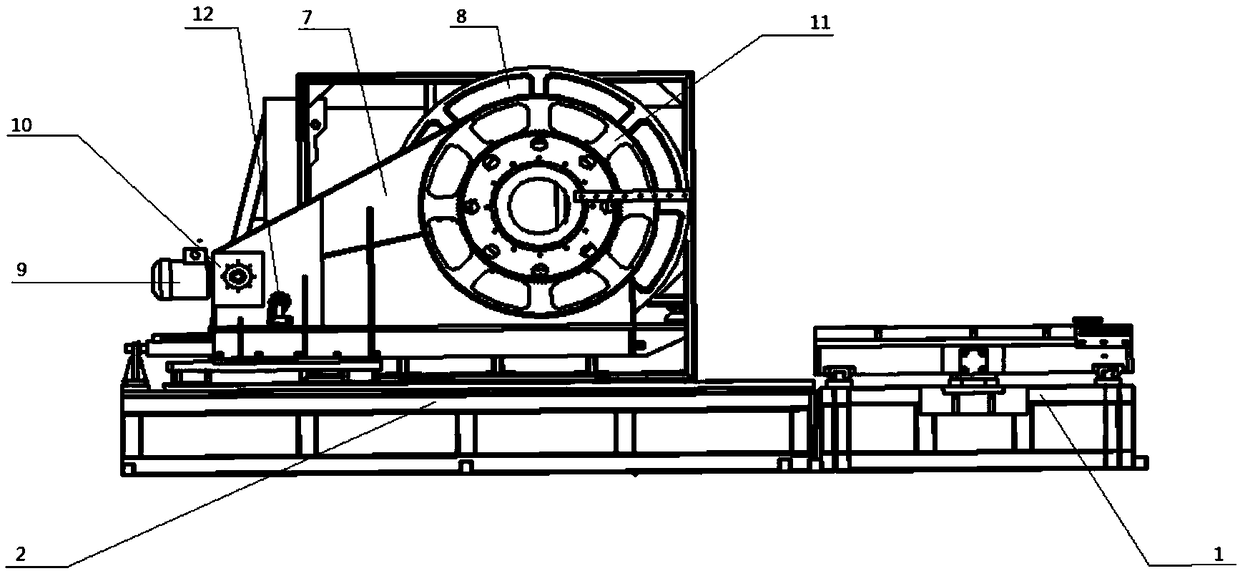

Laser pipe cutting and discharging all-in-one machine

PendingCN113953655AGet rid of dependenceReduce labor costsLaser beam welding apparatusEngineeringMachine

The invention provides a laser pipe cutting and discharging all-in-one machine. The laser pipe cutting and discharging all-in-one machine comprises a feeding chuck and a laser head perpendicular to the feeding direction of the feeding chuck, wherein a pulling-off unit capable of clamping and fixing a cut pipe section is arranged below the laser head, a material collecting unit is arranged below the pulling-off unit, and the pipe section can move on the material collecting unit to enter a material collecting frame. The laser pipe cutting and discharging all-in-one machine has the advantages that the cut pipe section is pulled off and taken down from a pipe through the pulling-off unit, then the cut pipe section is automatically released to the material collecting unit and can automatically enter the material collecting frame, and therefore manual operation is not needed, dependence on the manual operation is avoided, the labor cost is reduced, and the automation level and the production efficiency are improved.

Owner:BAOLONG ANHUI AUTO PARTS

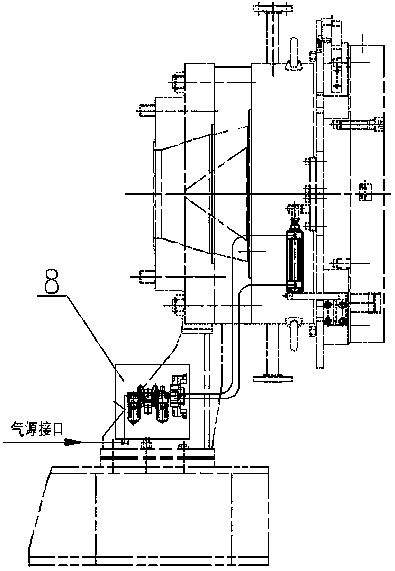

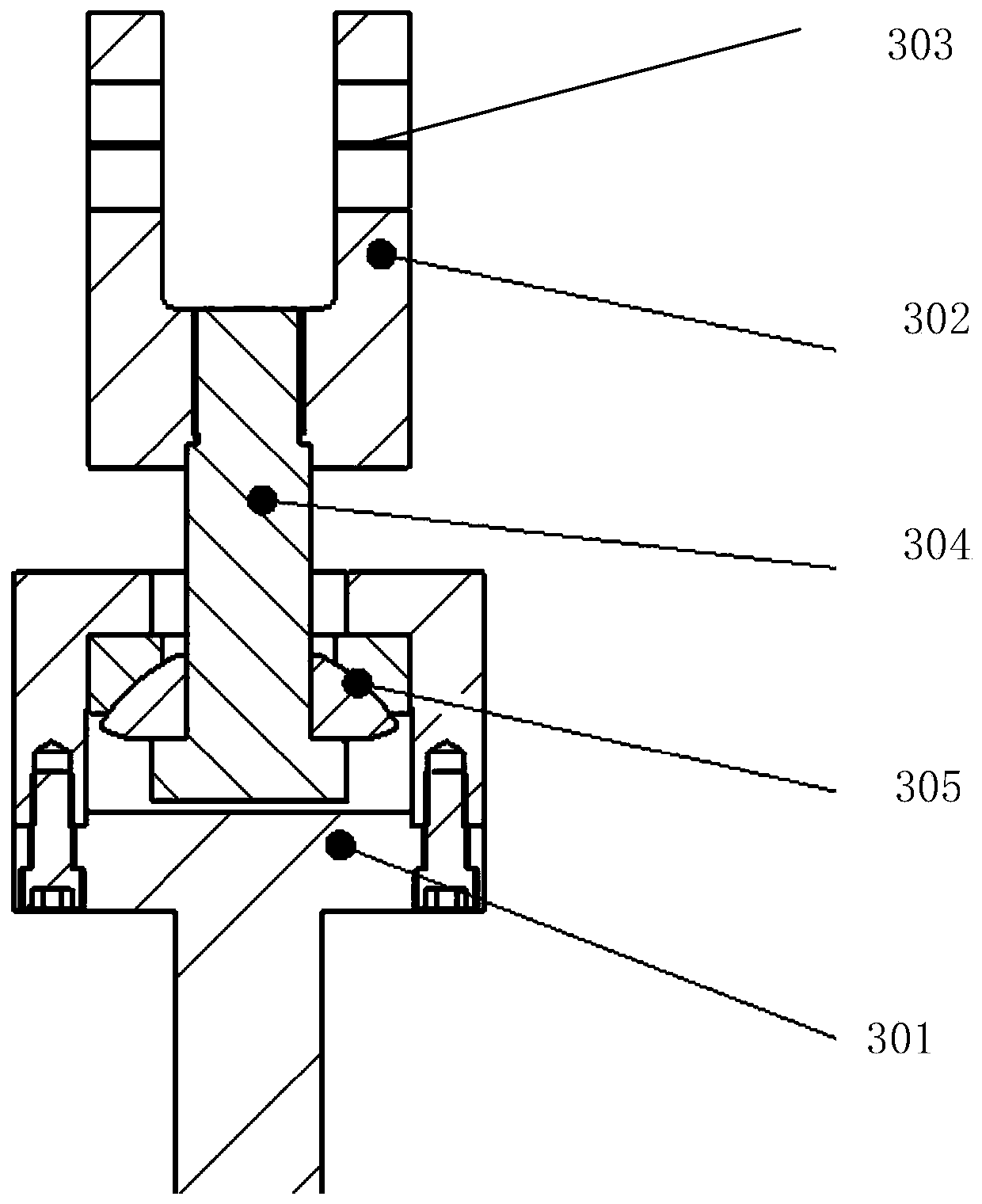

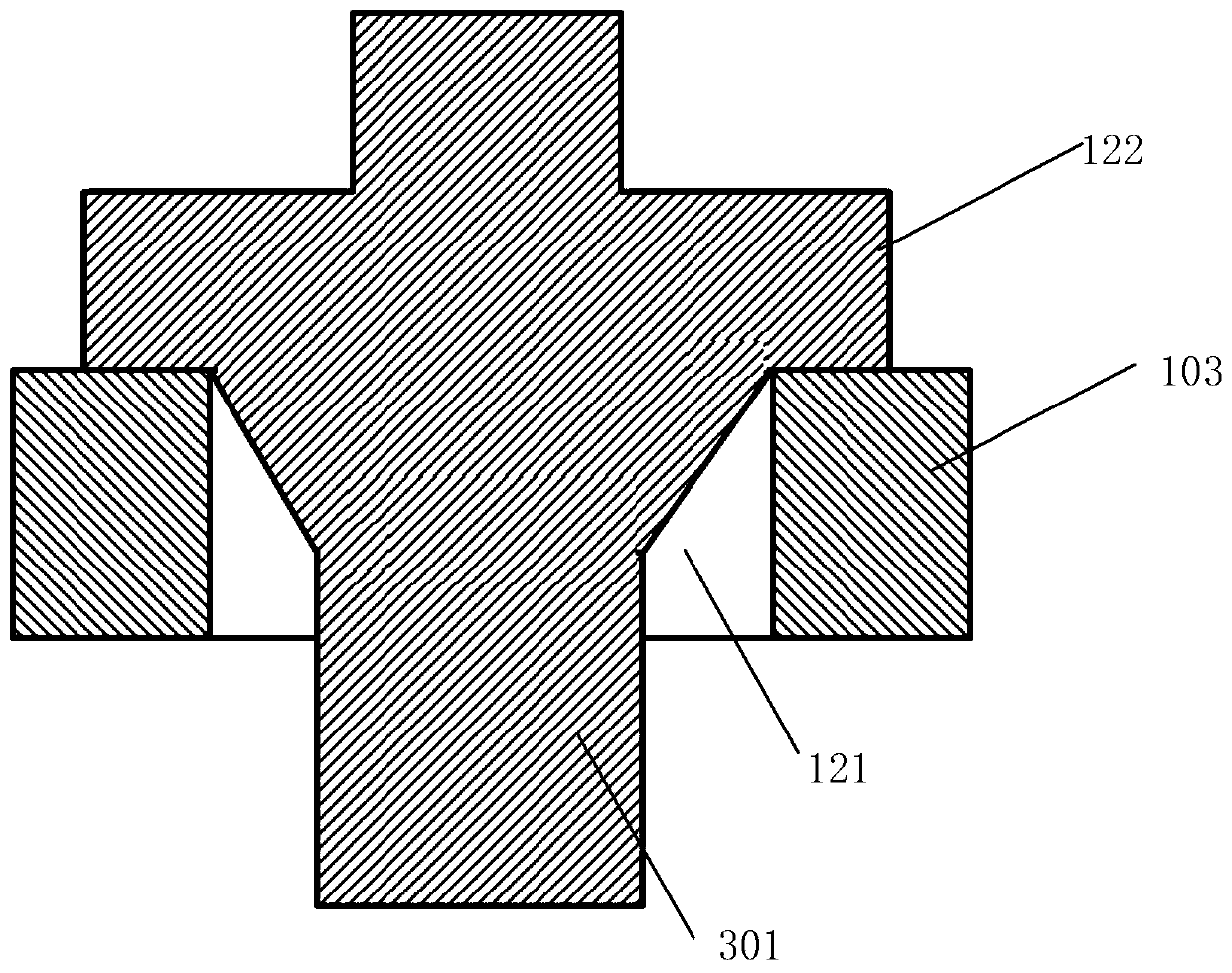

Large granulating unit machine head locking device

The invention discloses a large granulating unit machine head locking device which comprises a machine head body, a position sensor, a sensor sensing frame, locking blocks, a moving frame, movement air cylinders, a guide frame and a pneumatic control system. The position sensor, the moving frame and the guide frame are arranged on the machine head body. The sensor sensing frame and the locking blocks are arranged on the moving frame. The piston rod ends of the movement air cylinders are connected with the moving frame, and the fixed ends of the movement air cylinders are connected with the machine head body. According to the large granulating unit machine head locking device, the locking blocks are pushed through the air cylinders on the two sides of the machine head body to move up and down in the vertical direction, the locking blocks are rapidly moved, manual operation is thoroughly avoided, the acting direction of the air cylinders is automatically controlled by the pneumatic control system, manual misoperation is eliminated, the locking blocks are controlled to be in locked and opened positions through signal feedback of the sensor sensing frame and the sensor, the locking blocks are in place accurately, and the movement track of the locking blocks is limited in the vertical direction always through the guide frame.

Owner:大连橡胶塑料机械有限公司

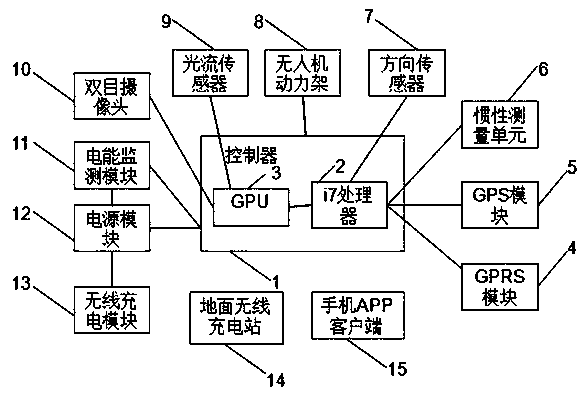

An automatic wireless rechargeable artificial intelligence drone

ActiveCN105959627BReduce manual operationsReduce labor costsBatteries circuit arrangementsRemote controlled aircraftUncrewed vehicleOptical flow

An automatic wireless rechargeable artificial intelligence unmanned aerial vehicle is characterized in that: it includes a controller; the controller includes: a GPU, an i7 processor; a GPRS module, a GPS module, an inertial measurement unit, and a direction sensor, respectively coupled On the i7 processor; optical flow sensor, installed on the bottom of the drone, coupled to the GPU; binocular camera, installed in front of the drone, coupled to the GPU; power monitoring module , coupled to the power module; the wireless charging module, coupled to the power module. The wireless charging module charges the power module through a ground wireless charging station. With the deep learning ability of artificial intelligence, it can modify the flight plan according to the changes when performing the flight mission, and can complete the charging task by itself.

Owner:上海佰恩智电子科技有限公司

Half-peak width automatic test tool

PendingCN113945591AImprove test efficiencyAchieve precise positioningMaterial analysis using radiation diffractionMechanical engineeringSignal processing

The invention discloses a half-peak width automatic test tool, and the half-peak width automatic test tool comprises an optical signal processing system which is used for generating a test signal based on a sample, wherein a sample stage in the optical signal processing system comprises a positioning structure which is used for positioning the sample; and a computer processing system which is in communication connection with the optical signal processing system and is used for receiving the test signal and realizing the automatic half-peak width test based on the test signal. The positioning structure is arranged on the sample table, the sample can be fixed on the sample table through the positioning structure, accurate positioning of a sample testing point is achieved, automatic testing can be achieved in cooperation with the computer processing system, manual operation in the prior art is avoided, and the testing efficiency is greatly improved.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Automatic assignment method, device, electronic map intelligent production system and navigation equipment

ActiveCN108241623BAvoid the pitfalls of line speed limit maintenanceAvoiding pitfalls of rate-limited maintenanceInstruments for road network navigationRoad vehicles traffic controlControl engineeringManual handling

The invention discloses an automatic value assignment method and device for line speed limit, an electronic map intelligent production system and navigation equipment. The method includes acquiring the point speed limit value in the road and the point speed limit direction corresponding to the point speed limit value; based on the preset automatic tracking principle, determining the initial road line and tracking direction to be assigned, planning the tracking path and determining The end road line to be assigned; determine the direction of the line speed limit assignment of the tracked road line according to the dashed direction of the tracked road line and the point speed limit direction corresponding to the point speed limit value, and according to the point limit The speed value and the direction of the line speed limit assignment of the tracked road line automatically perform line speed limit assignment processing on the tracked road line. The invention can make the maintenance of line speed limit free from heavy manual operation, complete the assignment of line speed limit by automatically tracking each road line, and can batch process a section of road, avoiding the defect of line speed limit maintenance one by one.

Owner:NAVINFO

Adhesive tape end-to-end connection equipment

The invention discloses adhesive tape end-to-end connection equipment which comprises an adhesive tape adsorption mechanism. According to the adhesive tape adsorption mechanism, the lower surfaces ofa first adhesive tape and a second adhesive tape are absorbed by utilizing negative pressure suction, the adhesive tape adsorption mechanism comprises a first adsorption area for adsorbing a tail partof the first adhesive tape and further comprises a second adsorption area for adsorbing a head part of the second adhesive tape, and the first adsorption area has a translational freedom degree capable of getting close to or being far away from the second adsorption area; a cutting mechanism is also included, has the vertical lifting freedom degree and comprises a first cutter and a second cutterwhich are used for cutting the first adhesive tape and the second adhesive tape correspondingly, the extending directions of cutting edges of the first cutter and the second cutter are parallel to each other, an acute included angle is formed between the extending directions of the cutting edges of the first cutter and the second cutter and the center line of the first adhesive tape, and the first cutter and the second cutter are both provided with single-sided edges; the respective edging surfaces of the first cutter and the second cutter are opposite or back to back; and a reinforcing adhesive tape is used for attaching and connecting the tail part of the first adhesive tape and the head part of the second adhesive tape, and a pressing block for pressing the reinforcing adhesive tape downwards is arranged above the reinforcing adhesive tape. By means of the adhesive tape end-to-end connection equipment, connection of different adhesive tapes is achieved, the efficiency is high, andthe strength is high.

Owner:FARO AUTOMATION (SUZHOU) CO LTD

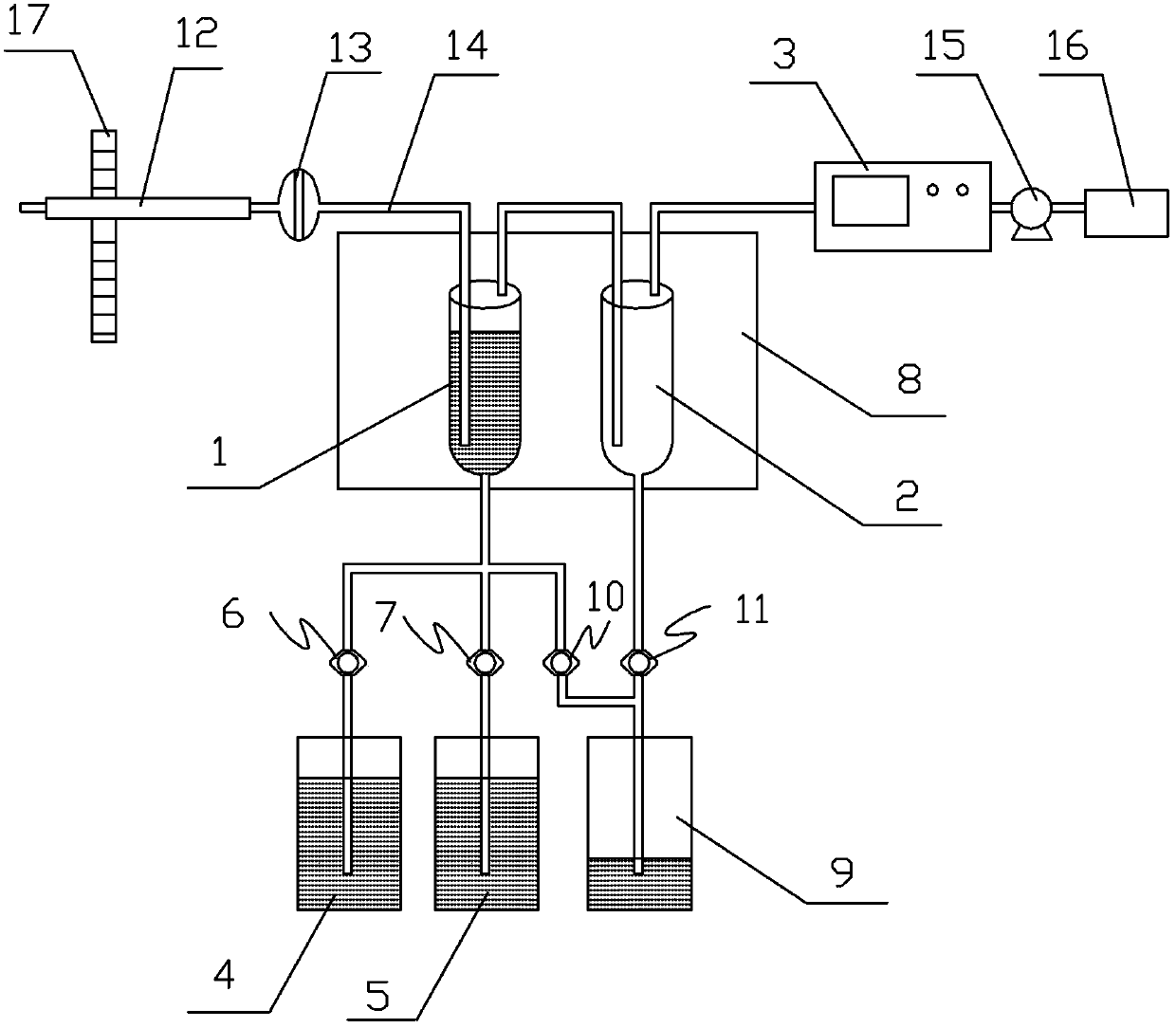

Mercury-containing fumes emission continuous monitoring system and monitoring method thereof

InactiveCN103293326BSimple structureReduce the possibility of leaksMaterial analysisElectricityPeristaltic pump

Owner:HANGZHOU AADTECH

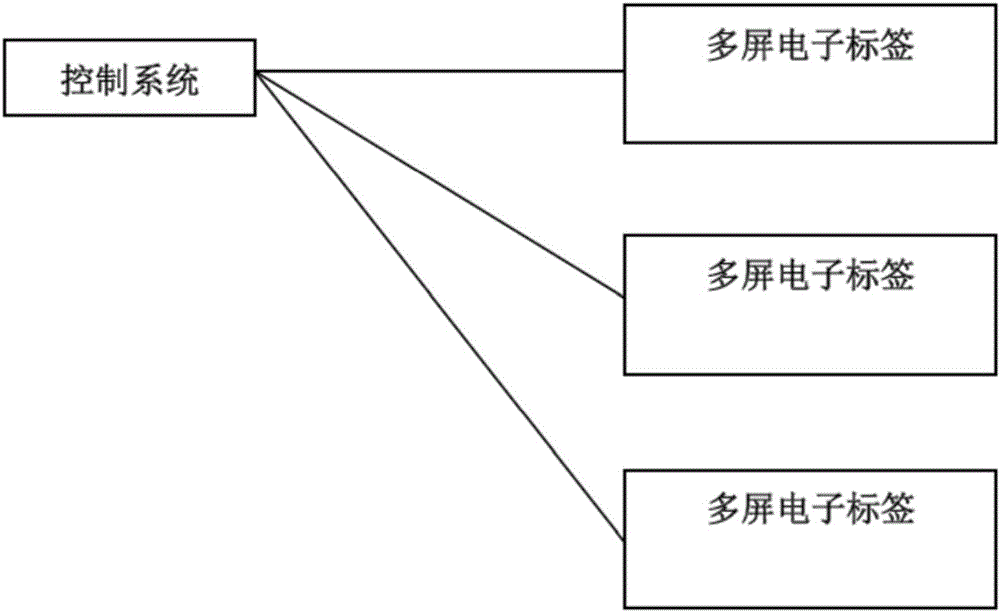

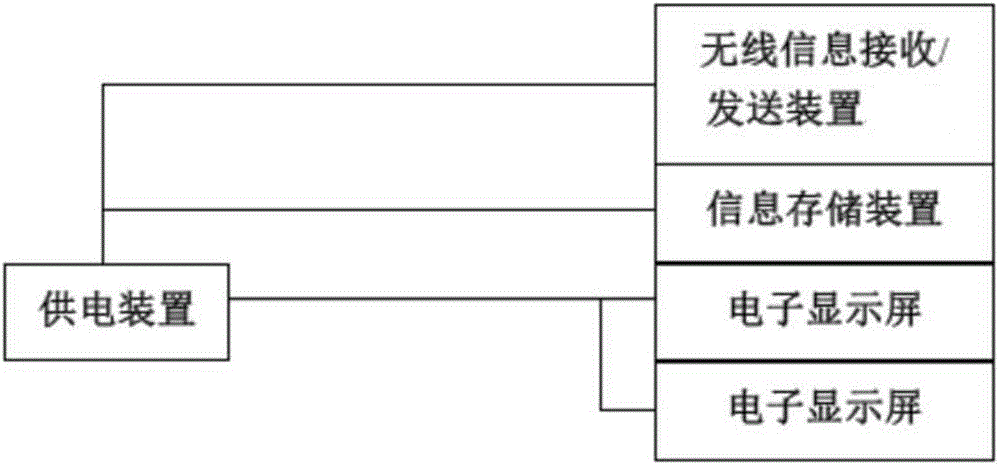

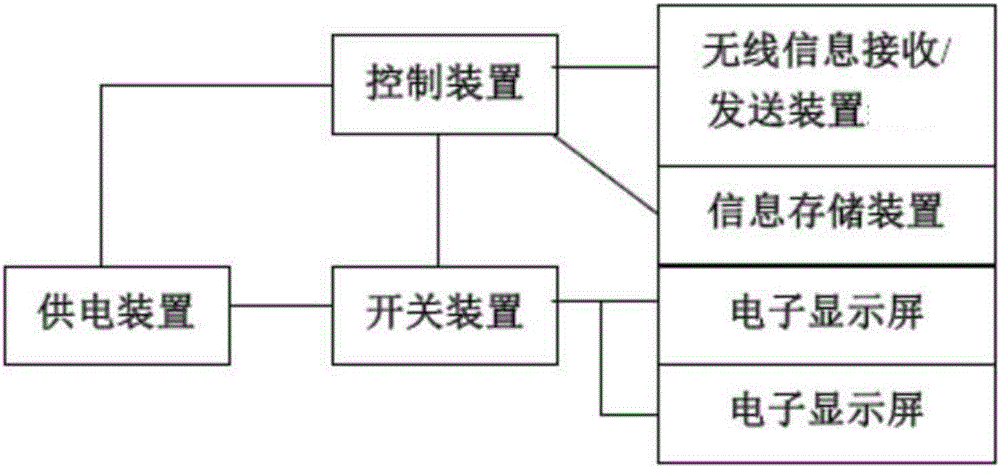

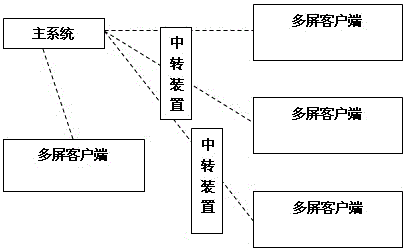

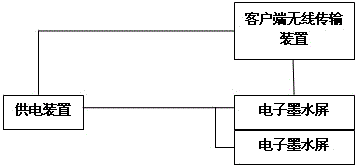

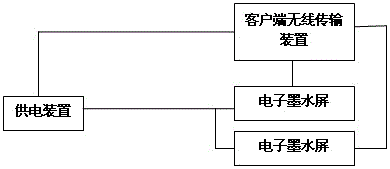

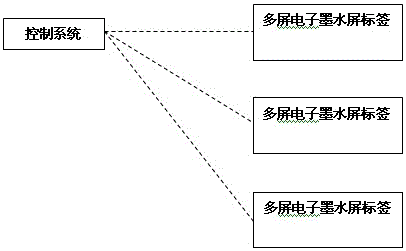

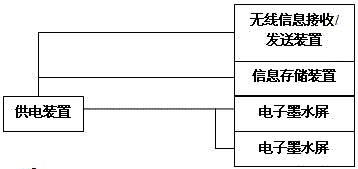

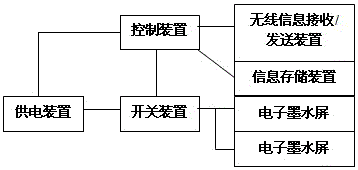

Storage type multi-screen electronic label display system and usage method

ActiveCN103594028BFull accessGet rid of manual operationStatic indicating devicesRecord carriers used with machinesInformation typeControl system

The invention discloses a storage type multi-screen electronic tag display system which comprises at least one multi-screen electronic tag and a control system. The multi-screen electronic tags comprise at least two display devices used for receiving information and displaying the information. The control system comprises a hardware system and a software managing system, wherein the hardware system can execute functions including information type-in, sending, receiving and processing under the software managing system. The control system is directly or indirectly connected with the multi-screen electronic tags in a wireless mode. The storage type multi-screen electronic tag display system has the advantages of avoiding primary and secondary waste of resources, getting rid of manual complex operation, improving efficiency and greatly reducing cost. In addition, the multi-screen combined type electronic tags can transmit more information at the same time, and therefore audiences can obtain more information at the same time.

Owner:TENWAY SHANGHAI INC

Discharging mechanism for vice jaw grinding device and application method thereof

InactiveCN112157490AImprove processing efficiencyCompact structureGrinding carriagesOther manufacturing equipments/toolsStructural engineeringManual handling

The invention discloses a discharging mechanism for a vice jaw grinding device and an application method thereof. The discharging mechanism comprises a mounting plate, a mounting hole, a fixing plate,mounting grooves, a bottom plate, a transmission mechanism, a mounting mechanism, a limiting mechanism, a limiting plate and a counter, wherein the fixing plate is fixedly connected to one end of thetop of the mounting plate; the mounting grooves are formed in the top of the fixing plate at equal intervals; the bottom plate is fixedly connected to the top of the fixing plate; and the transmission mechanism is arranged on one side of the fixing plate. The discharging mechanism for the vice jaw grinding device provided by the invention is compact in structure, easy and convenient to operate and high in practicability; the limiting mechanism and the mounting mechanism are arranged to be matched with each other, so that vices needing to be machined can be placed in order; and meanwhile, thetransmission mechanism is arranged, so that the vices placed in order can be discharged one by one, a vice grinding device can be better matched for use, the vice machining efficiency is improved, traditional manual operation is avoided, and potential safety hazards are greatly reduced.

Owner:湖南精专自动化技术有限公司

Hot melting angle welding machine and control method thereof

The invention discloses a hot melting angle welding machine and a control method thereof. The hot melting angle welding machine includes: a first frame; a first clamp arranged on the first frame and used for clamping a first tubing and a second clamp arranged on the first frame and used for clamping a second tubing, a first driving device used for driving the first clamp to move in a linear direction is arranged between the first clamp and the first frame, a second driving device used for driving the second clamp to move in a linear direction is arranged between the second clamp and the firstframe, and the first clamp and the second clamp are close to or away from each other; a second frame, wherein the second frame is provided with a milling cutter part, a hot plate part, a milling cutter driving device used for driving the milling cutter part to move to a second position from a first position, and a hot plate driving device used for driving the hot plate part to move to the second position from the first position; and a control system used for controlling the first driving device, the second driving device, the milling cutter driving device and the hot plate driving device. Thehot melting angle welding machine adopting the above structure gets rid of manual operation, and improves the welding quality and the welding efficiency.

Owner:罗森博格(无锡)管道技术有限公司

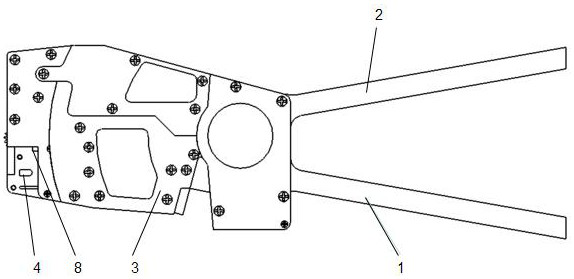

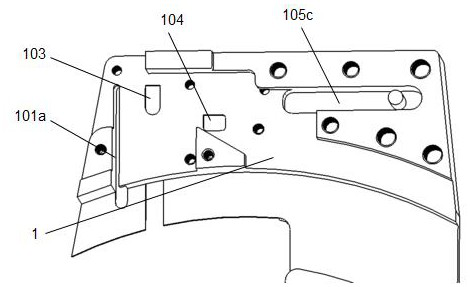

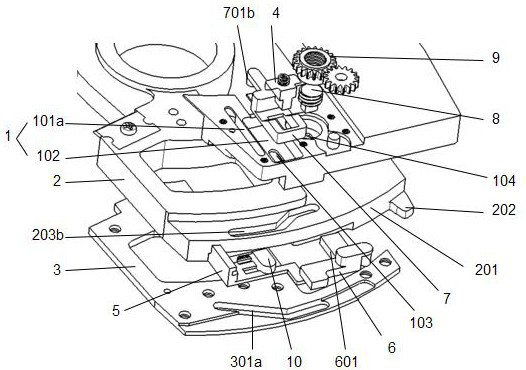

Wire folding pliers

Owner:张炜秋

Abdominal belt type dust collection robot used in plate cutting machining process

ActiveCN112828737AGet rid of manual operationReduce generationGrinding carriagesGrinding drivesElectric machineryEngineering

The invention relates to the technical field of plate machining, in particular to an abdominal belt type dust collection robot used in the plate cutting machining process. The robot comprises a box body, a motor and a fixing plate, wherein a grinding mechanism is arranged at the top of the box body, a through hole is arranged in the position, close to each pressing plate, of the box body, a second dust collector is fixedly arranged in each through hole in the box body, and a second dust storage bag is fixedly arranged at the top end of each second dust collector. Dust generated when a grinding disc works is adsorbed through a first dust collector, the dust amount in the box body is reduced, the dust adsorbed by the first dust collector is contained in a first dust storage bag to be stored, and therefore floating of the dust in the box body is reduced; and the first dust collector is arranged at the top end of the pressing plate, the first dust collector is closest to the grinding disc, and dust generated when the grinding disc works can be adsorbed by the first dust collector at the first time, so that dust generated in the box body is effectively reduced.

Owner:河南恒源鑫电力杆塔有限公司

A method for using multi-screen electronic information transmission in supermarkets and shops

ActiveCN103594038BGet rid of manual operationImprove efficiencyStatic indicating devicesRecord carriers used with machinesActive feedbackClient-side

The invention discloses a supermarket shop multi-screen electronic information transmission application method. The method includes the steps of information generation and transmission, information receiving and information display and information active feedback and display refresh. Multi-screen client sides can refresh display information automatically or periodically or under manual operation and comprise multiple display screens for information display. By the adoption of the supermarket shop multi-screen electronic information transmission application method, resources can be saved, operation is more conveniently and quickly conducted, labor is saved, cost is lowered, efficiency is improved, and more information can be provided.

Owner:TENWAY SHANGHAI INC

Flexible fixed length automatic cutting device for sheet material

InactiveCN1256226CEasy to adjustEasy to cut to lengthVeneer manufactureProduction rateLeveling mechanism

The invention is a flexible and fixed-length automatic cutting device for plates produced by rotary cutting of logs. Mechanism, pre-flattening mechanism, cutting mechanism and rear conveying mechanism are connected on the frame, which is connected with the plate traveling guide rail, the electromagnet movable armature of the electric control mechanism is connected with the movable blade of the cutting knife of the cutting mechanism, and the photoelectric switch is fixed on the In the discharging direction of the cutting mechanism, the power mechanism is connected with the front guide and the rear conveying drive. The front guiding mechanism, the pre-flattening mechanism, the cutting mechanism and the rear conveying mechanism are sequentially connected to the plate traveling guide rail on the frame. This kind of plate flexible fixed-length automatic cutting device not only gets rid of manual operation, but also has accurate fixed-length detection, fast cutting action, safe and economical working process, can conveniently adjust the cutting length according to different requirements, and achieve the purpose of cutting depending on the production speed of the plate. .

Owner:姚运仕 +1

Fully automatic branching system for enameled wire equipment

ActiveCN105097129BRealize automatic branchingGet rid of manual operationInsulating conductors/cablesEngineeringWire drawing

The invention provides a full-automatic branching system for enamelled wire equipment. The full-automatic branching system comprises an outlet wire feeding roller and a painted part wire feeding roller, wherein a front servo motor is connected with the outlet wire feeding roller and drives the outlet wire feeding roller; a rear servo motor is connected with the painted part wire feeding roller and drives the paint part wire feeding roller; a lead steel strip is wound on a drum which is coaxial with the outlet wire feeding roller and a drum which is coaxial with the painted part wire feeding roller; a steel strip running motor is connected with the lead steel strip and drives the lead steel strip; the full-automatic branching system is characterized in that a front wire drawing head is arranged correspondingly to the outlet wire feeding roller, and is fixedly arranged at the tail end of a cylinder rod of a front wire drawing cylinder; the front wire drawing cylinder is matched with a screw nut to be connected on a left-and-right wire drawing front screw rod; and a front left-and-right operation motor is connected with the left-and-right wire drawing front screw rod and drives the left-and-right wire drawing front screw rod. The full-automatic branching system is provided with a front wire drawing system and a rear wire drawing system; branching actions of the wire drawing heads are reached through coordination of the cylinder and the nut screw, so that automatic branching is realized; the manual branching operation is casted off; and the work efficiency is improved.

Owner:常州市清和机械设备有限公司

Storage type multi-screen electronic ink screen label display system and using method

ActiveCN103594035BGuaranteed display effectSave electricityStatic indicating devicesRecord carriers used with machinesIndirect couplingControl system

The invention discloses a storage type multi-screen electronic ink screen label display system, comprising a multi-screen electronic ink screen label with at least two electronic ink screens for receiving and displaying information; a control system, the control system including a hardware system and a software management system, the hardware system performs functions including inputting, sending, receiving, and processing of information under the software management system; the control system and the multi-screen electronic ink screen label conduct direct or Indirect connection, the multi-screen electronic ink screen label is at least one; the present invention can avoid primary and secondary waste of resources, and can get rid of manual cumbersome operations, so that the advantages of efficiency improvement and cost reduction are greatly reduced; at the same time, multi-screen electronic ink Screen tags can convey more information at the same time, so the audience can get more information at the same time.

Owner:TENWAY SHANGHAI INC

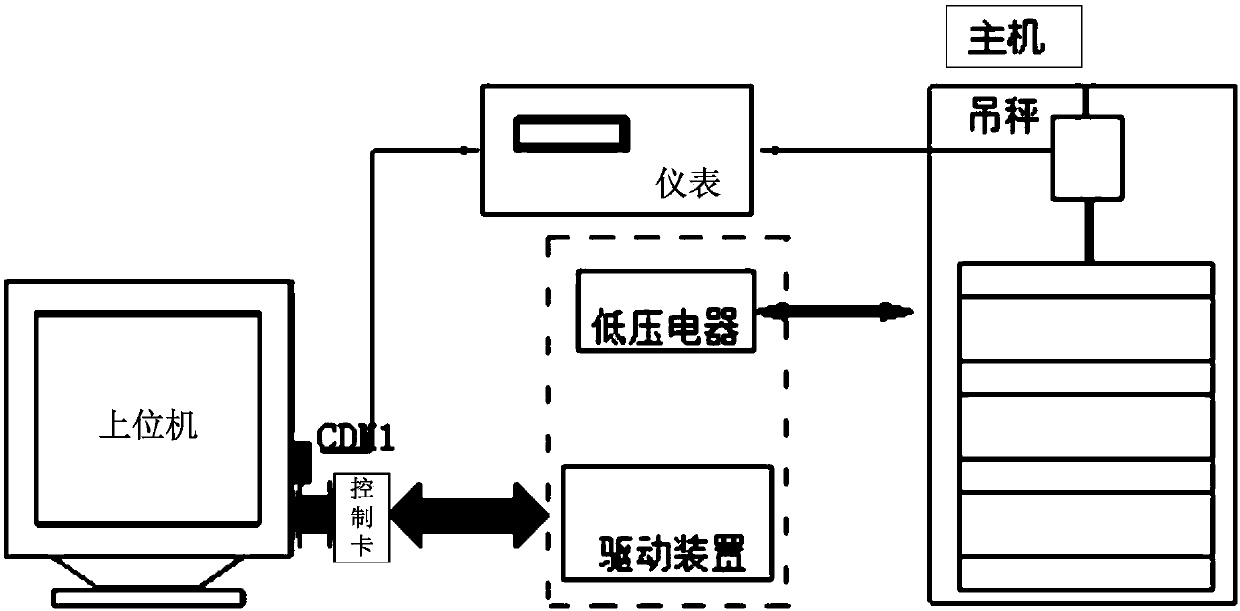

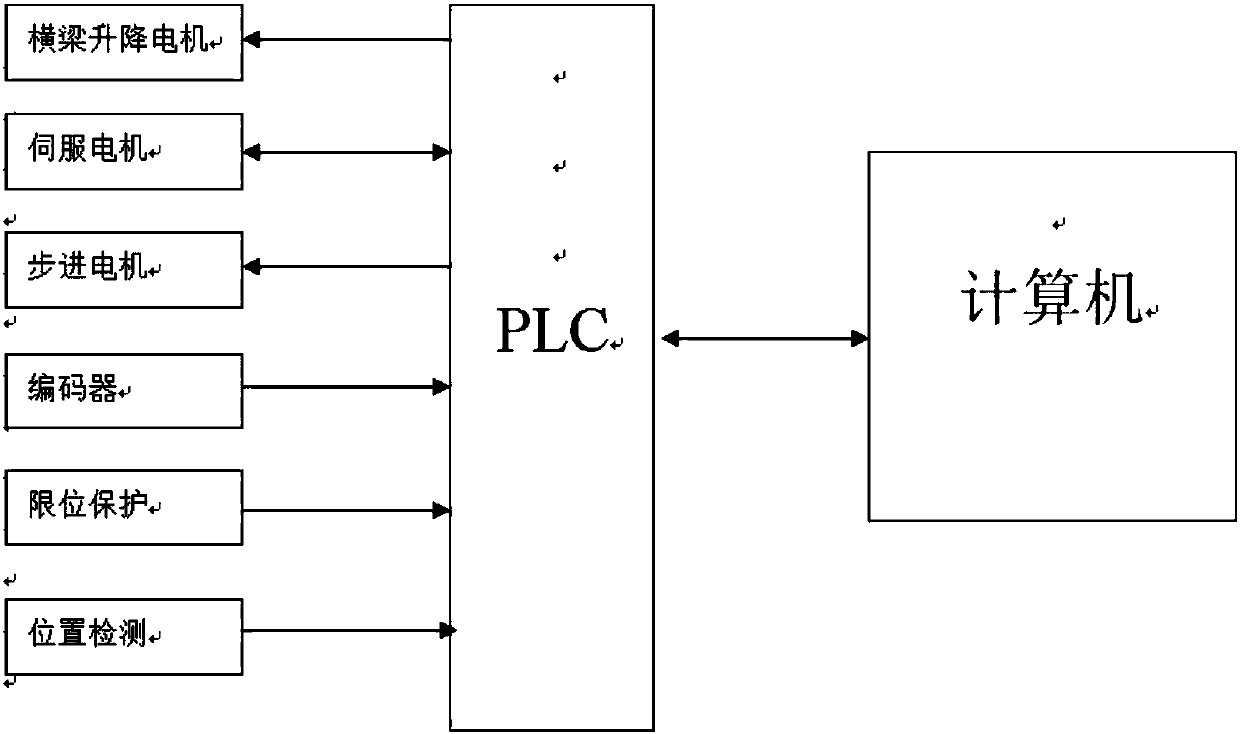

An electronic crane scale automatic detection device

ActiveCN108469296BRealize the loadImprove efficiencyWeighing apparatus testing/calibrationDiscrimination thresholdDrive motor

The invention discloses an automatic detecting device of an electric hanging scale. The device comprises a hanging mechanism, a mainframe framework, a weight connecting device, a weight loading device, a discrimination threshold detecting device and a weight dismantling device; the discrimination threshold detecting device comprises a discrimination threshold platform and multiple detecting weightautomatic loading mechanisms, the up-and-down movement of a lifting rod is controlled by a discrimination threshold driving motor, and therefore a second weight group can be loaded or unloaded relative to the discrimination threshold platform; a manner of inner and outer ring weight group is adopted by the weight loading system, the height of the weight mechanism is reduced properly, the safety performance is higher, and the loading working efficiency is higher due to simultaneous loading of inner and outer rings. The detection of the automated dismantling of a large large-tonnage weight group of the electric hanging scale can be achieved by the weight dismantling device, the dismantling efficiency of weights is improved, and labor cost is saved. By means of the automatic detecting device, fully-automated detection of the electric hanging scale can be achieved by the arrangement of the hanging mechanism, the weight connecting device, the mainframe framework and the weight loading device.

Owner:苏州市计量测试研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com