Nested type electronic hoist scale weight loading system

An electronic crane scale and loading system technology, which is applied in the field of weight loading system, can solve the problems of low detection accuracy, affecting measurement accuracy, and many weight loading points, so as to get rid of manual operation, high loading work efficiency, and ensure safety Effects on Sexuality and Productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

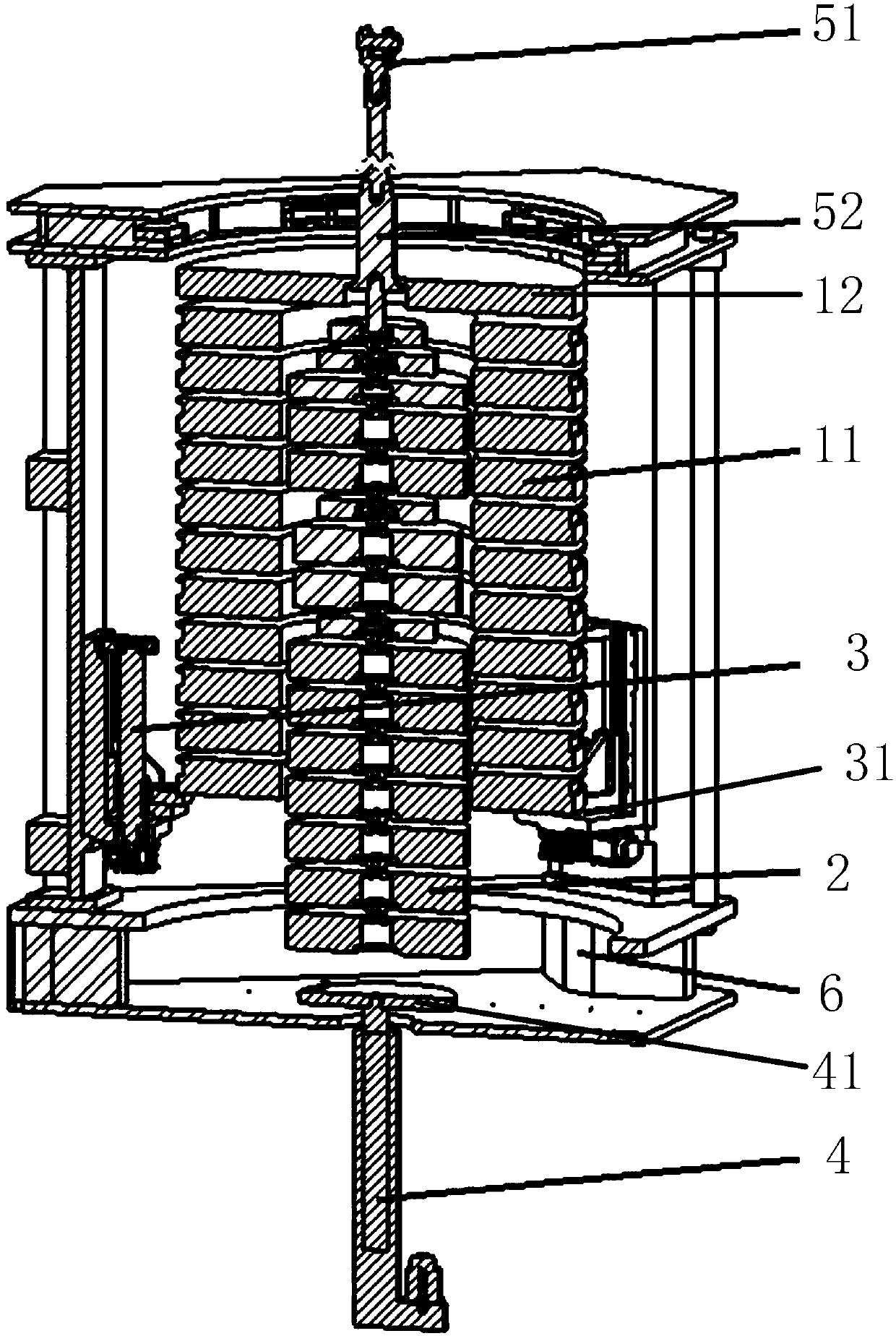

[0026] See figure 1 , the present invention provides a nested electronic crane scale weight loading system, comprising: an outer ring weight group, an inner ring weight group, an outer ring weight driving mechanism 3, an inner ring weight driving mechanism 4 and a hanging connecting mechanism;

[0027] The outer ring weight group includes a plurality of stacked outer ring weights, and the adjacent outer ring weights are suspended and connected;

[0028] The inner ring weight group includes a plurality of stacked inner ring weights 2, and two adjacent inner ring weights are connected by hanging;

[0029] The inner ring weight group is nested in the outer ring weight group, and the uppermost inner ring weight 2 is connected to the hanging connection mechanism; the outer ring weight group is connected to the hanging connection mechanism through the inner ring weight group;

[0030] The inner ring weight driving mechanism 4 is used to support the inner ring weight group, and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com