Side leaking photon crystal optical fiber and producing method thereof

A technology of photonic crystal fiber and leaky type, which is applied in the direction of cladding fiber, optical waveguide light guide, glass manufacturing equipment, etc., can solve the problems of long scrambled mode length of single-polarization single-mode photonic crystal fiber, strict process requirements, and difficult production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

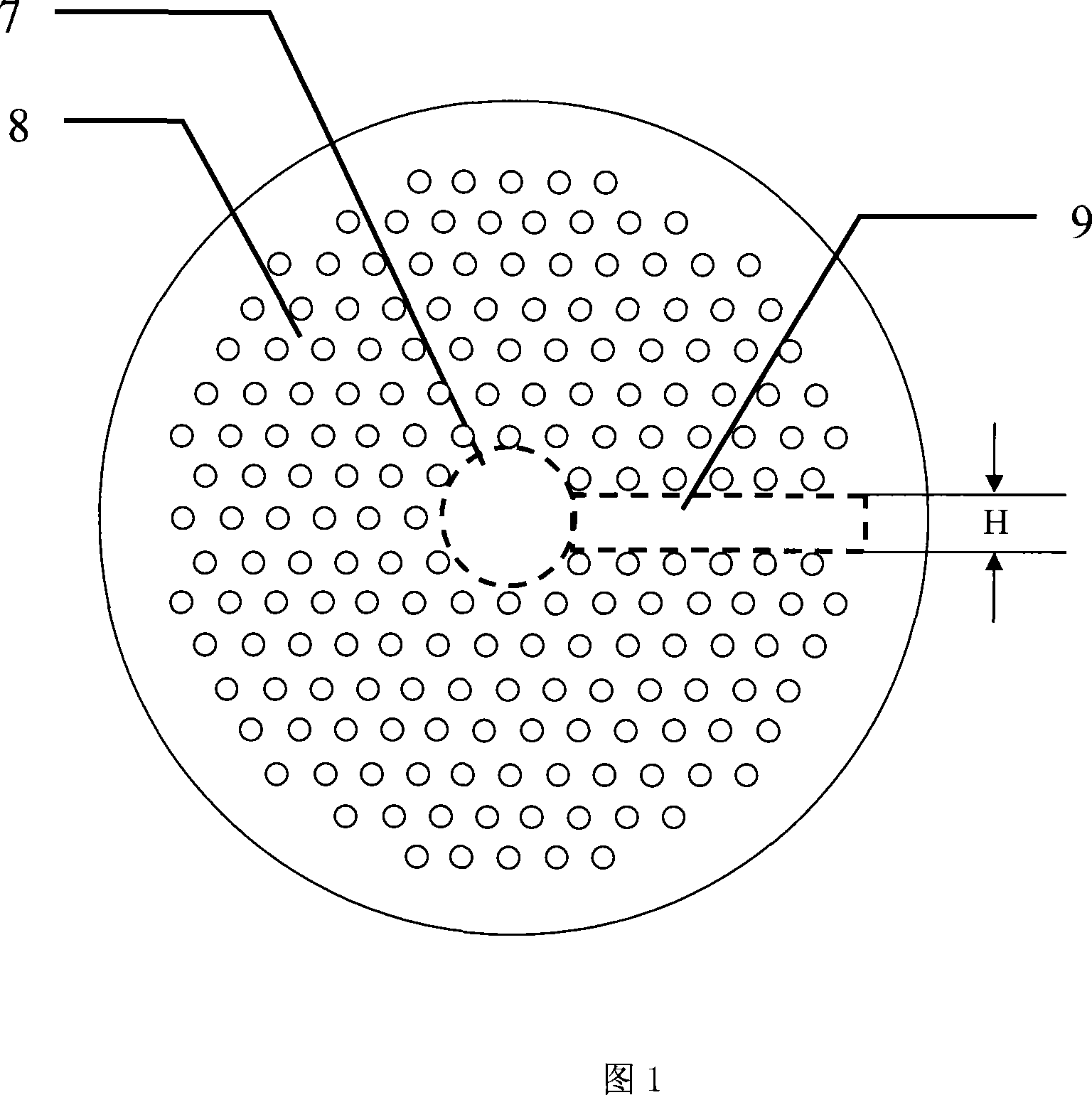

[0021] Embodiment 1: a high equivalent refractive index linear area side leakage type triangular lattice quartz photonic crystal fiber, the cross-sectional structure is shown in Figure 1, it includes a pure silica high refractive index core region 7 that transmits light waves and surrounds the core region 7 and The cladding region 8 that constrains the transmission of light waves, the cladding region 8 is a low equivalent refractive index region formed by capillary pores parallel to the axial direction and arranged in a triangular lattice. The structural feature of the present invention is: there is a The region 7 is parallel to the pure quartz high equivalent refractive index linear region 9 extending outward from the core region 7 through the cladding region 8, and the cross-sectional height H of the pure quartz high equivalent refractive index linear region 9 is half the wavelength of the transmitted light value.

[0022] A side-leakage triangular lattice quartz photonic cr...

Embodiment 2

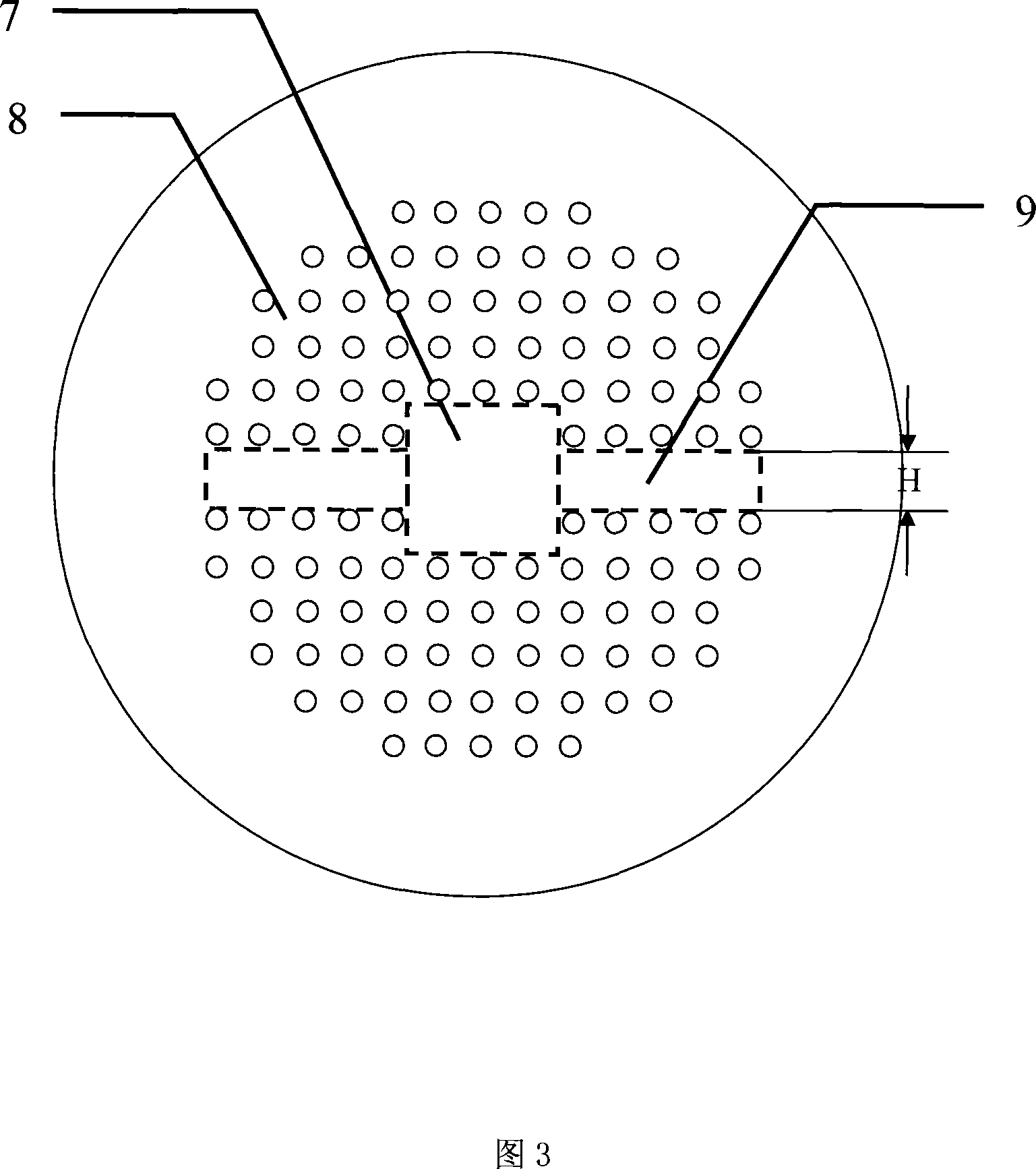

[0026]Embodiment 2: Symmetrical high equivalent refractive index linear region side leakage type square lattice polymer photonic crystal fiber, the cross-sectional structure is shown in Figure 3, it includes a perfluorinated polyethylene vinyl ether high refractive index core region 7 that transmits light waves And the cladding region 8 that surrounds the core region 7 and acts as a constraint on the transmitted light wave. The cladding region 8 is a low equivalent refractive index region formed by capillary pores parallel to the axial direction and arranged in a square lattice manner. The structural characteristics of the present invention are : There are two perfluorinated polyethylene vinyl ether high equivalent refractive index linear regions 9 parallel to the optical fiber core region 7 and extending outward from the core region 7 through the cladding region 8, and the perfluorinated polyethylene vinyl ether high equivalent The cross-sectional height H of the linear region...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com