Hot melting angle welding machine and control method thereof

A welding machine and angle technology, applied in the field of hot-melt angle welding machine and control, can solve the problems of low work efficiency, high labor intensity, large randomness of pipeline welding quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The purpose of the present invention is to provide a hot-melt angle welding machine, which can automatically complete the milling of pipes and welding through system control, get rid of manual operation, and improve the quality and efficiency of welding.

[0033] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the Example shown below does not limit the content of the invention described in a claim. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solutions of the invention described in the claims.

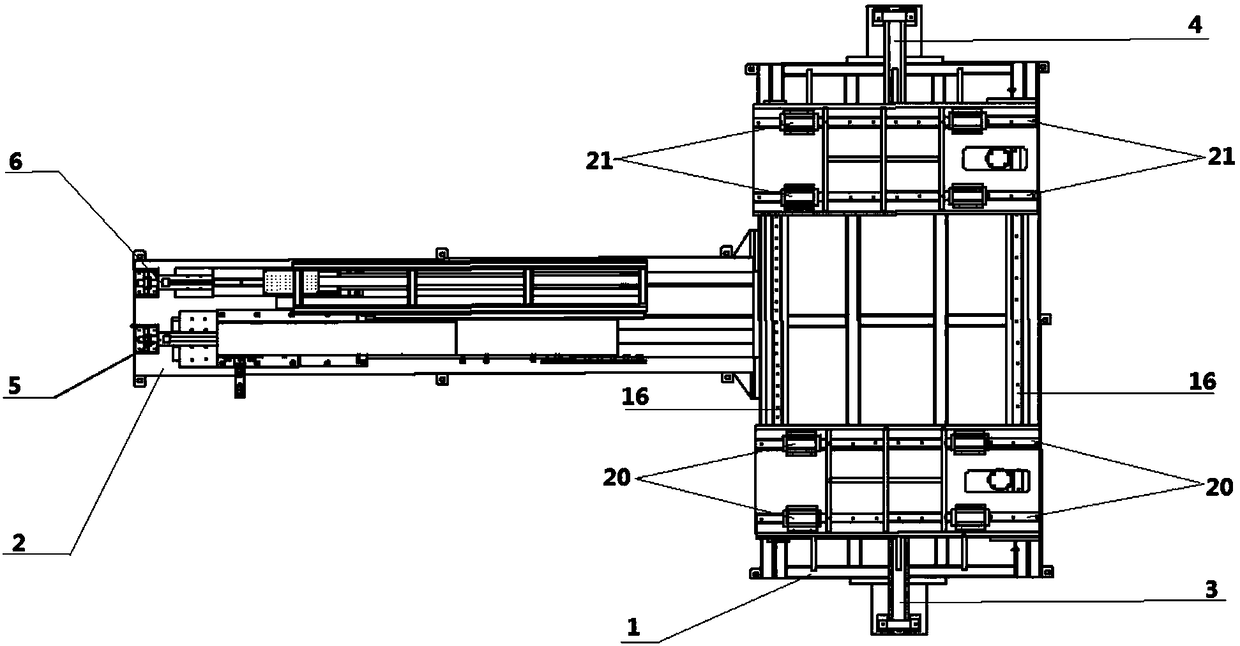

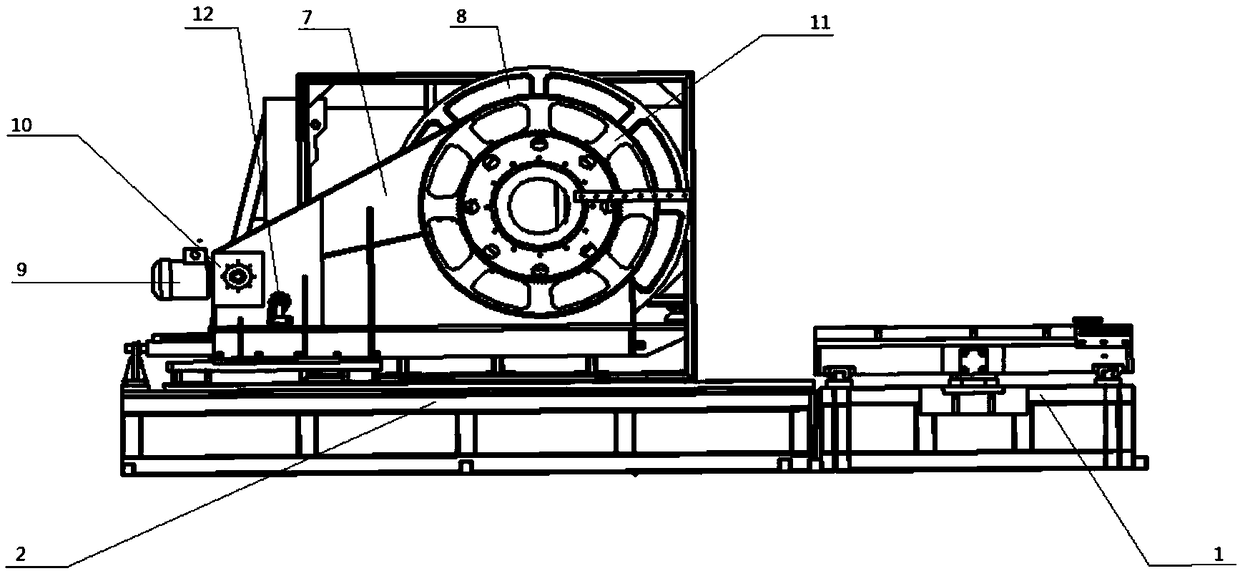

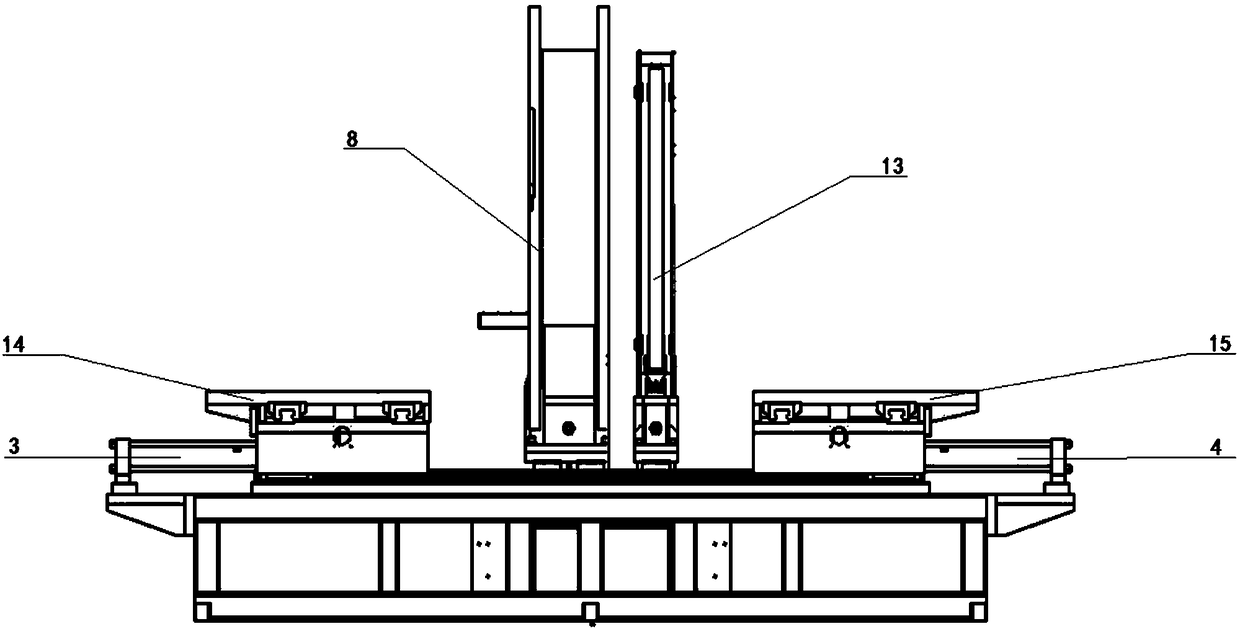

[0034] refer to Figure 1-Figure 3 Among them, a hot-melt angle welding machine, including: a first frame 1, a second frame 2 and a control system;

[0035] The first frame 1 is provided with a first clamp for clamping the first pipe and a second clamp for clamping the second pipe, the first clamp and the second clamp are detachably connected to the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com