Abdominal belt type dust collection robot used in plate cutting machining process

A technology of cutting processing and robotics, which is applied in metal processing equipment, manufacturing tools, grinding racks, etc., can solve problems such as harm and affecting the quality of plate surface grinding and polishing, and achieve the effect of getting rid of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

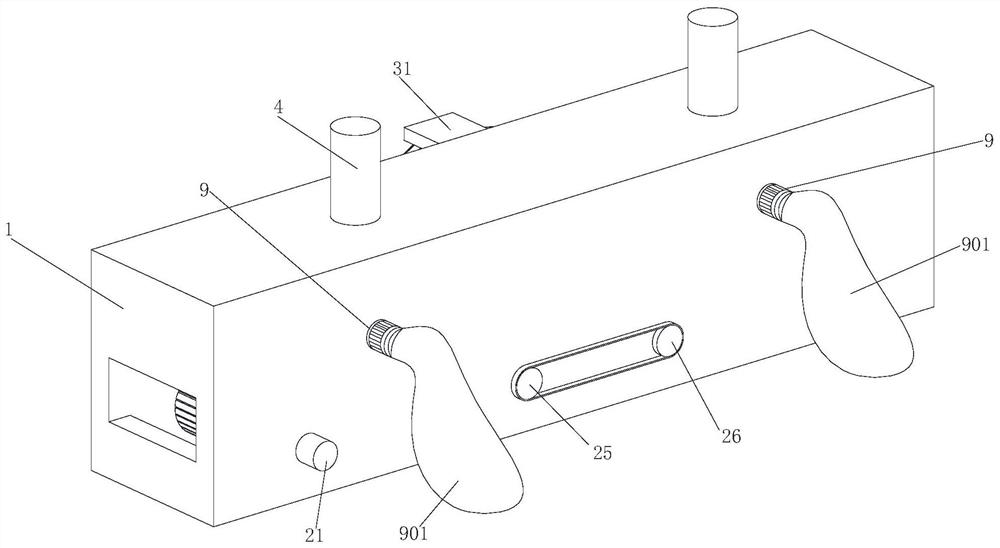

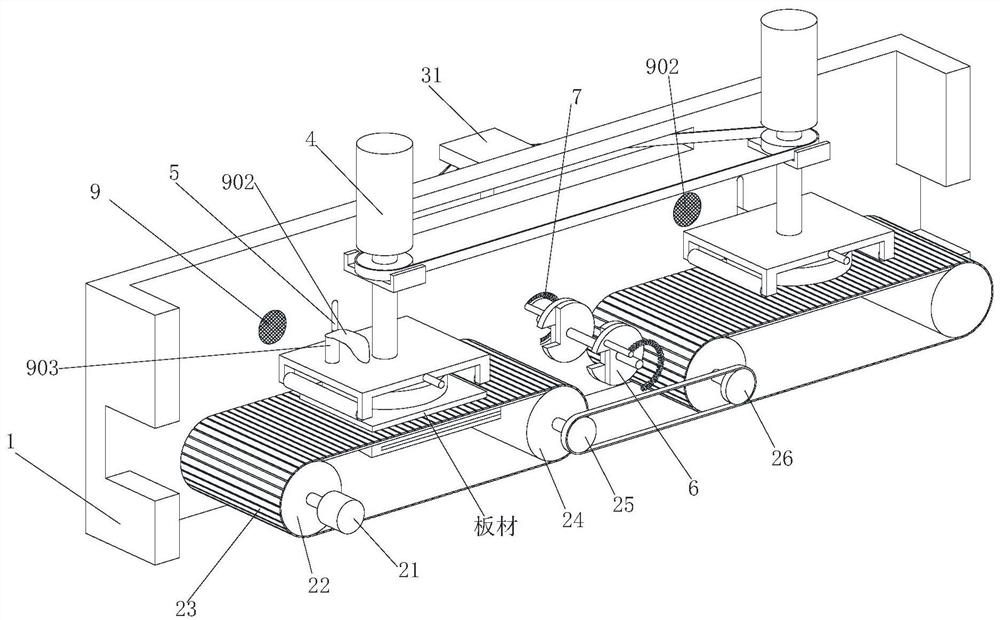

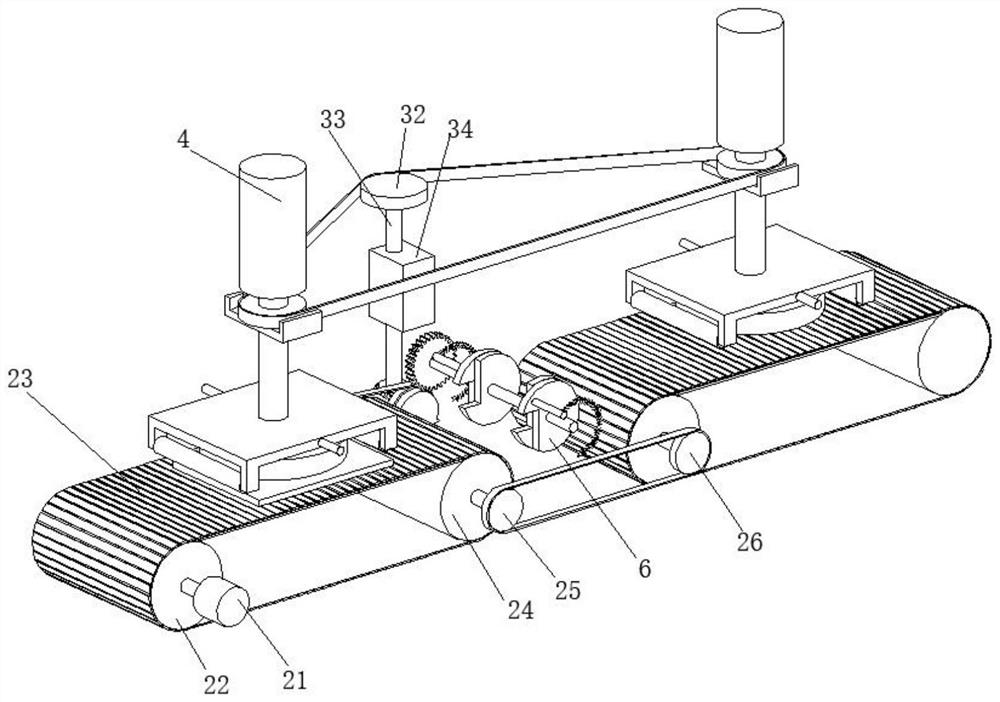

[0043] A belt-type vacuuming robot in the process of plate cutting, such as Figure 1-Figure 7 As shown, it includes a box body 1, a motor 21 and a fixed plate 31. The top of the box body 1 is provided with a grinding mechanism 4. The inner wall of the box body 1 is respectively provided with a slot 5 and a chute 7, and the chute 7 is located in the slot 5. The rear portion of the box body 1 is provided with a turning mechanism 6, and the shape of the chute 7 is C-shaped.

[0044] The output end of the motor 21 is welded with a No. 1 drum 22, and the surface of the No. 1 drum 22 is connected with the surface transmission of the No. 2 drum 24 through a conveyor belt 23. The right end of the No. 2 drum 24 is welded with a No. 1 pulley 25 through a connecting rod, and the No. 1 pulley 25 The surface is connected with the surface drive of the second pulley 26 by a belt.

[0045] The bottom of fixed plate 31 is rotatably connected with transmission rod 33, and the surface of trans...

Embodiment 2

[0052] This embodiment is another embodiment of a belly-belt-type vacuuming robot in the process of plate cutting. This example has similarities with the content of Embodiment 1, and the similarities will not be repeated in this embodiment. The specific differences are:

[0053] Such as Figure 8 As shown, the turning mechanism 6 includes a transmission shaft 61, two No. 1 chucks 62 are welded on the surface of the transmission shaft 61, and two No. 2 chucks 63 are rotatably connected to the surface of the transmission shaft 61.

[0054] The left side of No. two chuck 63 is welded limit bar 64, and the inwall of casing 1 is fixedly installed with back-moving spring 65, and the shape of back-moving spring 65 is C character shape, and No. two chuck 63 can be exerted force by back-moving spring 65, makes It and the rotating No. 1 chuck 62 clamp the sheet metal to prevent the sheet material from falling when it drives the sheet metal to rotate, and then smash the machine, increas...

Embodiment 3

[0058] This embodiment is another embodiment of a belly-belt-type vacuuming robot in the process of plate cutting. This example has similarities with the content of Embodiment 1, and the similarities will not be repeated in this embodiment. The specific differences are:

[0059] Such as Figure 9-12 As shown, the grinding disc 49 includes a third chute 4901 equally spaced on the bottom surface of the grinding disc 49, and several grinding blocks 4903 arranged on the bottom surface of the grinding disc 49, and a polishing block is also arranged between two adjacent grinding blocks 4903. 4907, the polishing blocks 4907 and the polishing blocks 4903 are alternately arranged on the bottom surface of the grinding disc 49 along the circumference, and the polishing blocks 4903 and the polishing blocks 4907 are alternately arranged to realize the function that the bottom surface of the grinding disc 49 can also be polished in the process of grinding the top surface of the material , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com