Stator stack thickness detector

A detection device and stator technology, applied in the direction of mechanical thickness measurement, etc., can solve the problems of inaccuracy, low efficiency, slow speed, etc., and achieve the effect of accurate detection results and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

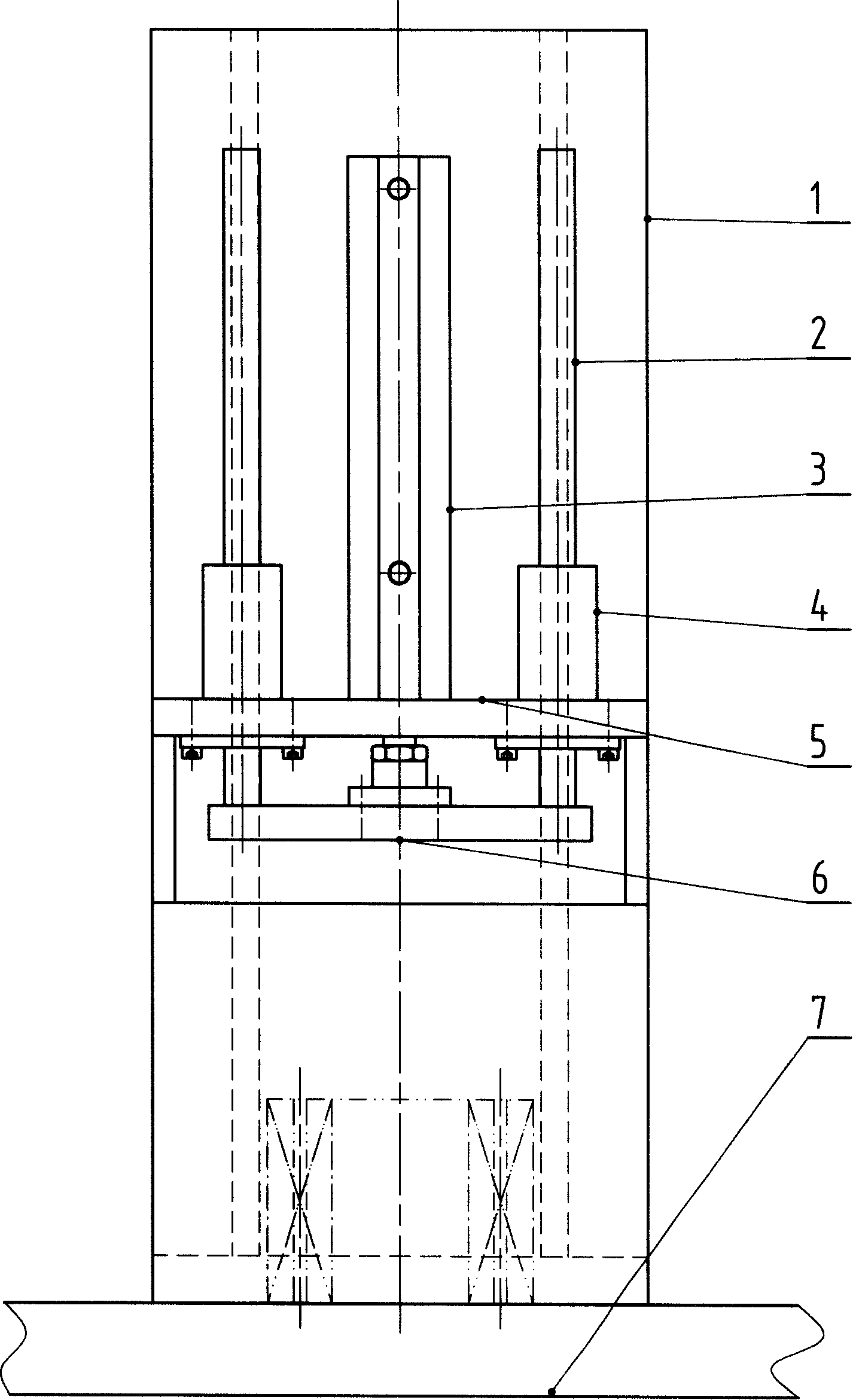

[0008] With reference to the accompanying drawings, a stator stack thickness detection device is provided with a base 1 on the panel 7, a support base 5 on one side of the base 1, a detection pressure plate 6 under the support base 5, and a stroke set on the upper end surface of the support base 5 The piston rod of the sensing cylinder 3 is fixedly connected, and a guide rod 2 is provided on the detection pressure plate 6, and the guide rod 2 is located in the guide sleeve 4 on the upper end surface of the support base 5. When in use, the stator stack thickness detection device is installed on the stator detection and marking slot assembly machine through the panel, and the operating stroke of the control system can be read out. The cylinder is guided by the guide rod to drive the detection pressure plate down to the stator core installation base surface, and measure Find a value and set this value as the reference value. Under the action of the control system, the stroke can be r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com