Adhesive tape end-to-end connection equipment

A tape, head and tail technology, applied in the field of tape head and tail connection equipment, can solve the problems of difficulty in manual cutting quality control, manual connection and paste operation difficulty, etc., to achieve the effect of convenient operation and reduced equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

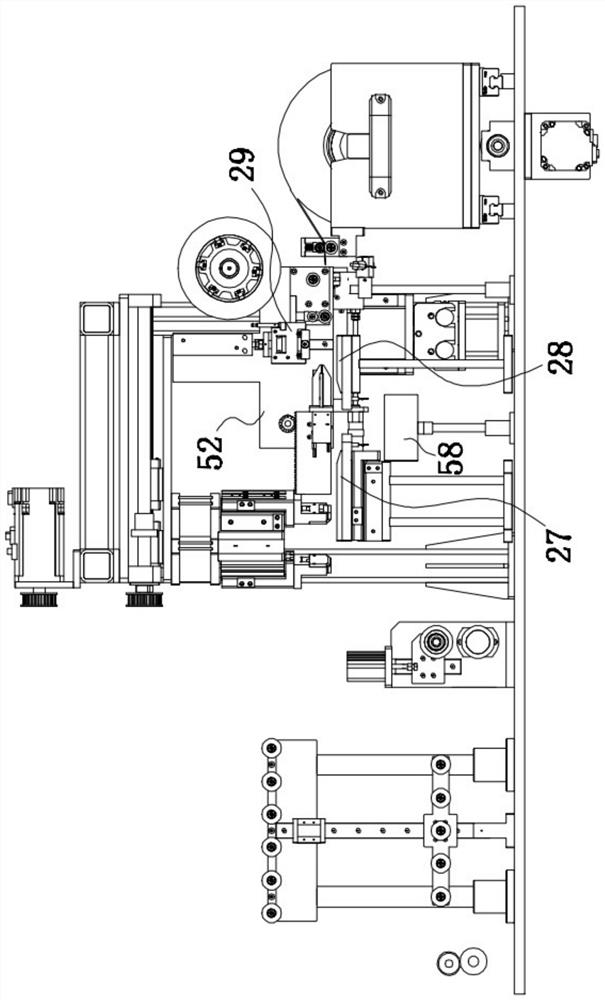

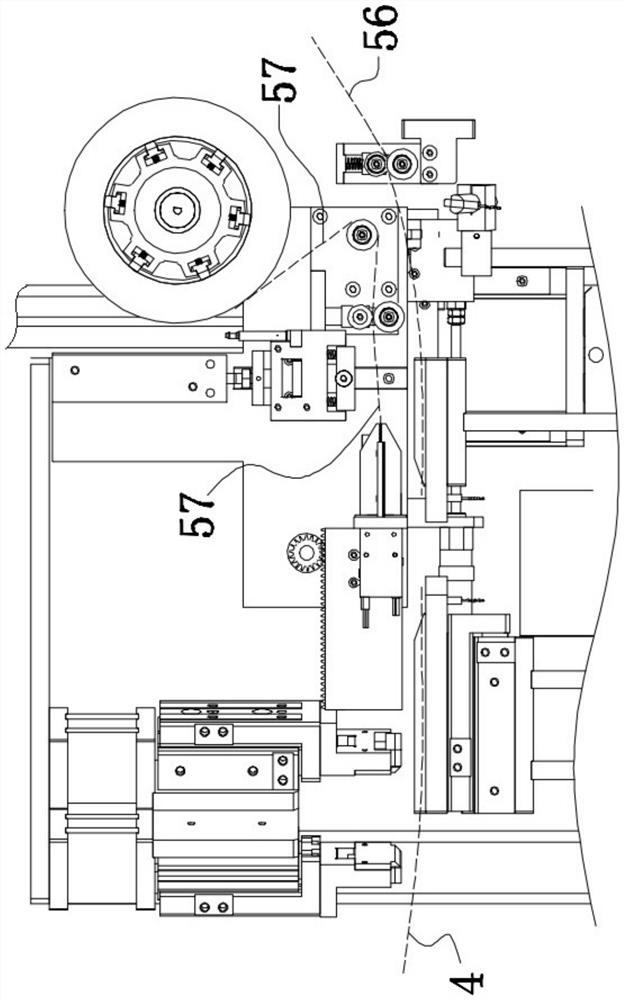

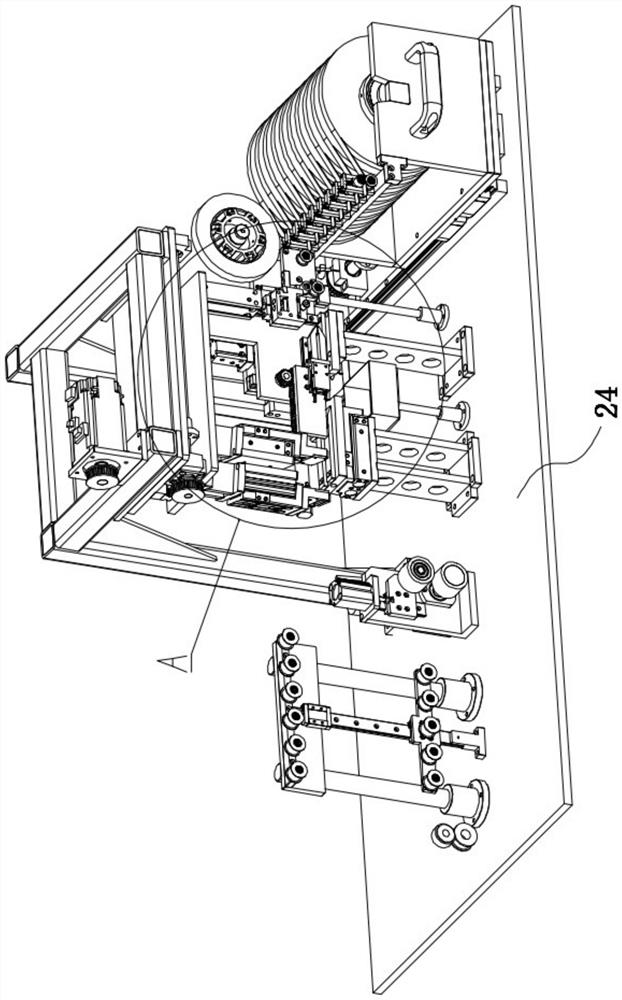

[0044] In order to achieve the purpose of the present invention, a tape head-to-tail connection device includes: a tape adsorption mechanism that utilizes negative pressure suction to adsorb the lower surfaces of the first adhesive tape 4 and the second adhesive tape 56, and the adhesive tape adsorption mechanism includes a device that absorbs the tail of the first adhesive tape 4 The first adsorption area 27 also includes the second adsorption area 28 that absorbs the head of the second adhesive tape 56. The first adsorption area 27 has a translational degree of freedom that is close to or far away from the second adsorption area 28. The first adsorption area 27 on the first adsorption area 27 An adhesive tape 4 and the center line of the second adhesive tape 56 on the second adsorption area 28 coincide on the same space straight line; the cutting mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com