Wire folding pliers

A technology of folding wire pliers and bending pliers, applied in the field of folding wire pliers, can solve problems such as laborious operation of electricians, potential safety hazards of electricity use, inconvenient operation, etc., and achieve the effect of getting rid of manual operation, uniform shape, and convenient use of shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

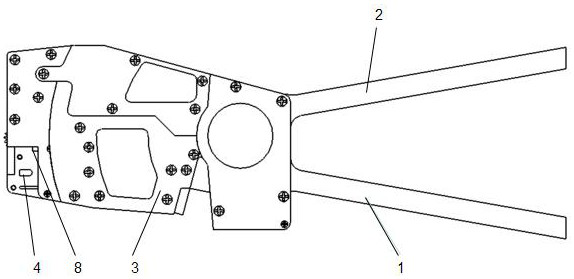

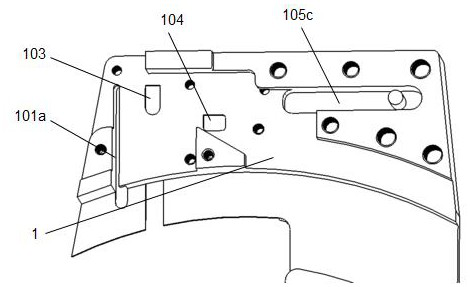

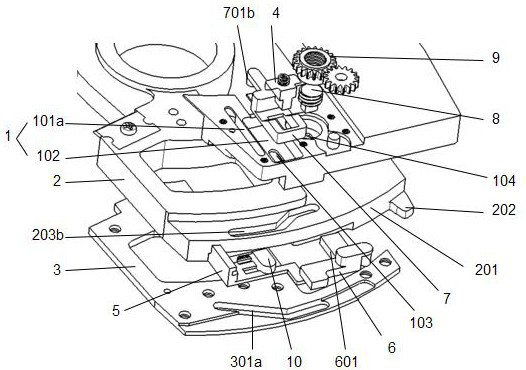

[0022] as attached figure 1 to attach Figure 5 As shown, it includes a first body 1 and a second body 2, the first body 1 and the second body 2 are rotatably connected, one end of the first body 1 is provided with sliding grooves 101a, 105c, and the sliding grooves 101a, 105c The folding line mechanism 5, 10 and the profiling slider 6 are respectively arranged inside, and the profiling slider 6 is arranged perpendicular to the folding line mechanism 5, 10, and the working surface of the first body 1 on one side of the folding line mechanism 5, 10 is provided with Through hole 103, the opposite side of the working surface of the first body 1 is provided with a sliding groove 102b corresponding to the through hole, and the sliding groove 102b is provided with a telescopic sliding mechanism 4, 7, and the folding line mechanism 5, 10 on the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com