Discharging mechanism for vice jaw grinding device and application method thereof

A vise and installation mechanism technology, which is applied in the direction of grinding frame, grinding machine parts, grinding bed, etc., can solve the problems of reducing the processing efficiency of vise, lack of automatic unloading mechanism, and increasing equipment safety hazards, etc., to achieve Compact structure, get rid of manual operation, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

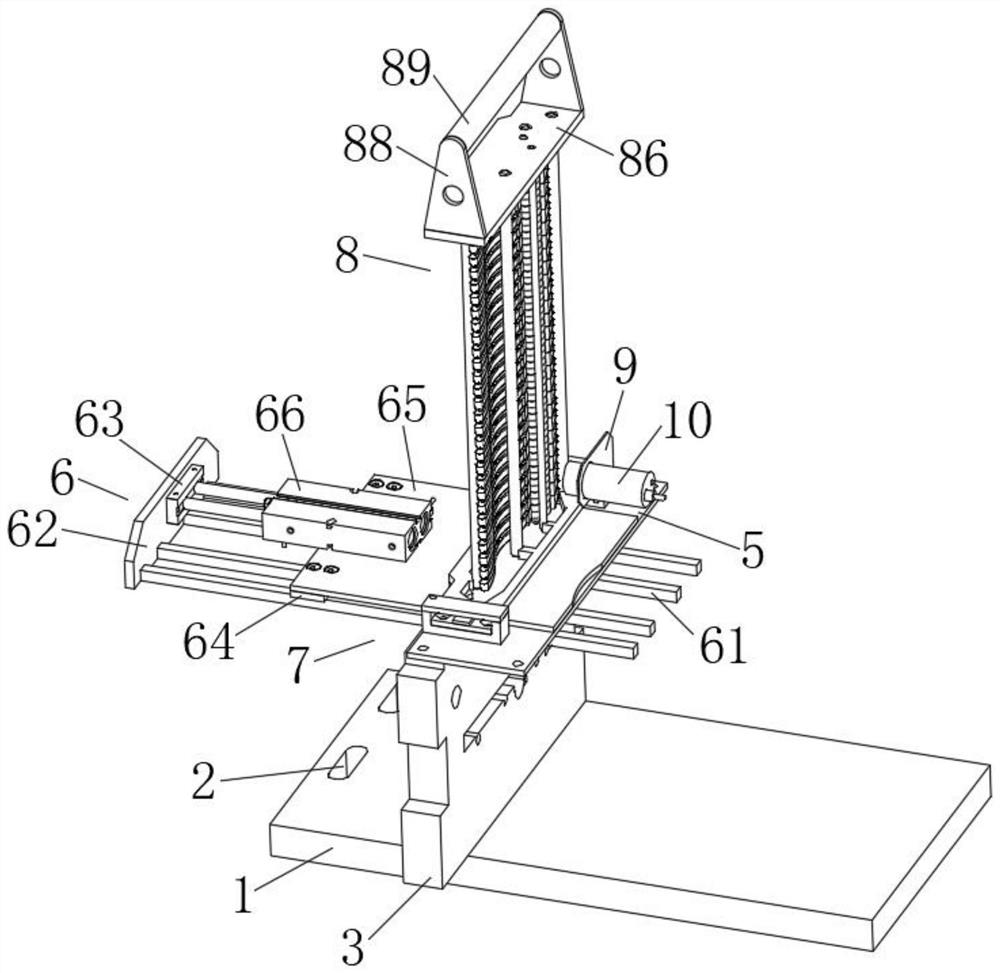

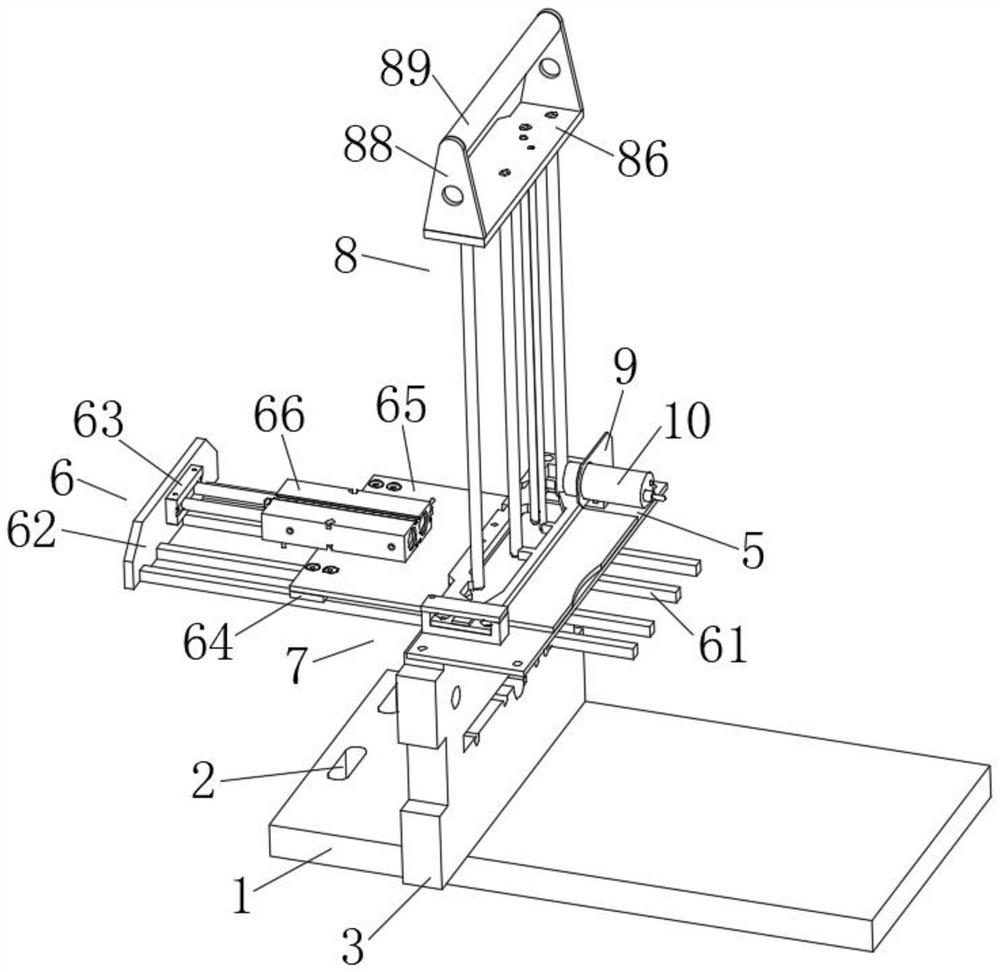

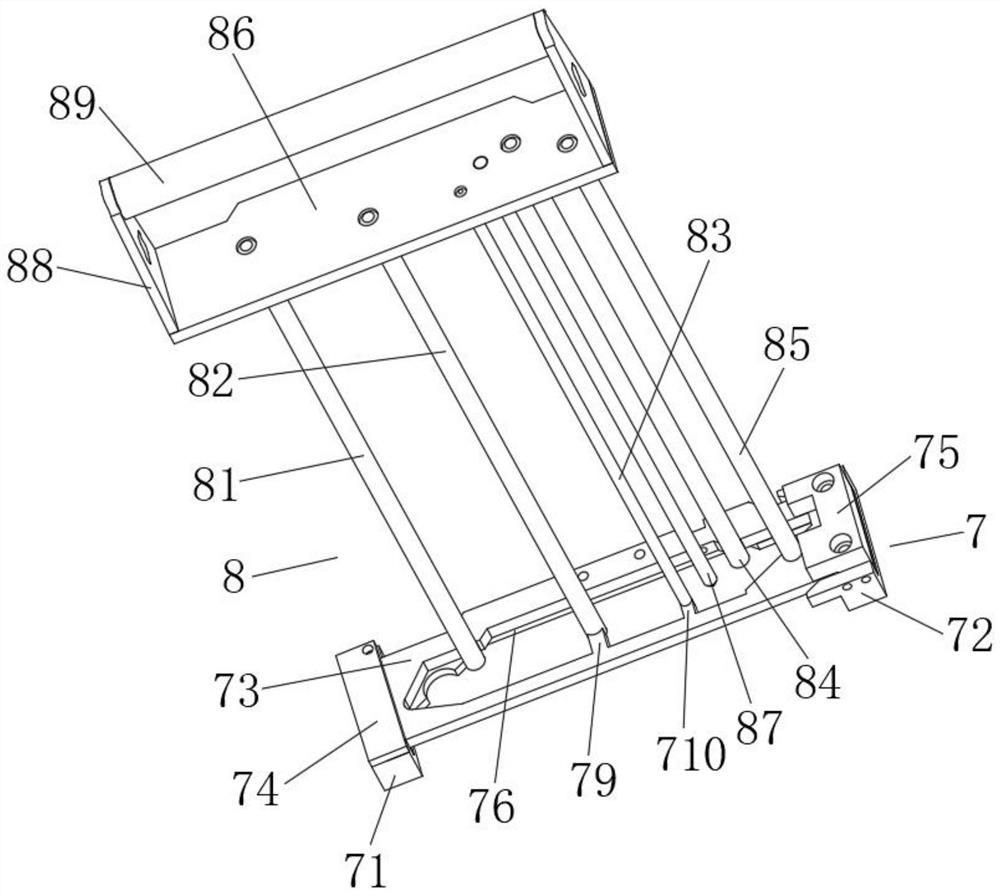

[0029] A blanking mechanism for a vise jaw grinding device, comprising a mounting plate 1, a mounting hole 2, a fixing plate 3, a mounting groove 4, a bottom plate 5, a transmission mechanism 6, a mounting mechanism 7, a limit mechanism 8, a limit plate 9 and Counter 10, one end of the top of the mounting plate 1 is fixedly connected with a fixed plate 3, the top of the fixed plate 3 is equidistantly provided with mounting grooves 4, the top of the fixed plate 3 is fixedly connected with a bottom plate 5, and the fixed plate 3 is provided with a transmission mechanism 6, the top of the bottom plate 5 is provided with a mounting mechanism 7, and the top of the mounting mechanism 7 is provided with a limit mechanism 8.

[0030] Wherein, the transmission mechanism 6 includes a fixed rod 61, a connecting plate 62, a connecting block 63, a slide plate 64, a moving plate 65 and a cylinder 66, and the inside of the installation groove 4 is fixedly connected with a fixed rod 61, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com