Miniature light-emitting component and manufacturing method thereof

A technology of light-emitting elements and manufacturing methods, which is applied in the direction of electrical elements, electric solid-state devices, semiconductor devices, etc., and can solve problems such as prone to broken bridges and dropped electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

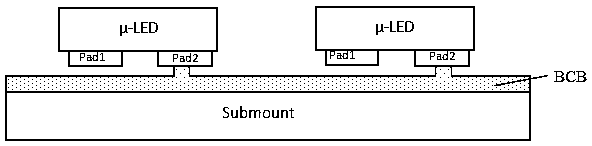

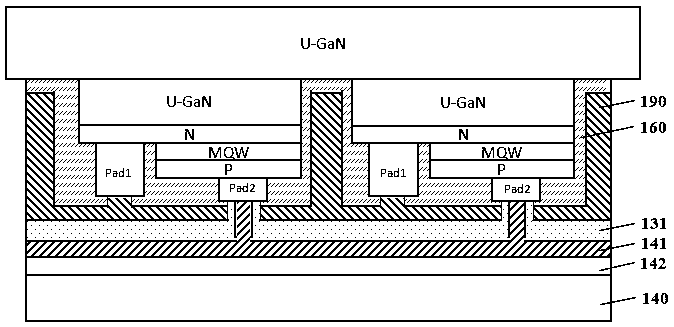

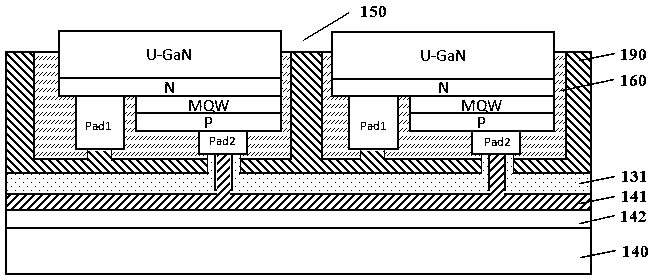

[0052] image 3(a) is the pattern on the lower surface of the micro light emitting diode chip in the first preferred embodiment. The micro light emitting diode includes: an epitaxial stack layer, which sequentially includes a first type semiconductor layer, an active layer, and a second type semiconductor layer. having opposite first and second surfaces; a first electrode formed on the second surface of the epitaxial stack and connected to the first type semiconductor layer; a second electrode formed on the epitaxial stack On the second surface of the second electrode, it is connected with the second type semiconductor layer; the first electrode is divided into a first region 121a, a second region 131a and a third region 141a from the inside to the outside at the center of the electrode, and the three Regions can be distinguished by surface topography or appearance color. The LED chip 110 is a thin-film microstructure, and its preferred size is within 100 μm×100 μm, such as 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com