Condensed milk tank packaging production line

A packaging production line and tank technology, applied in the field of condensed milk tank packaging production line, can solve the problems of increased production costs, large water consumption, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

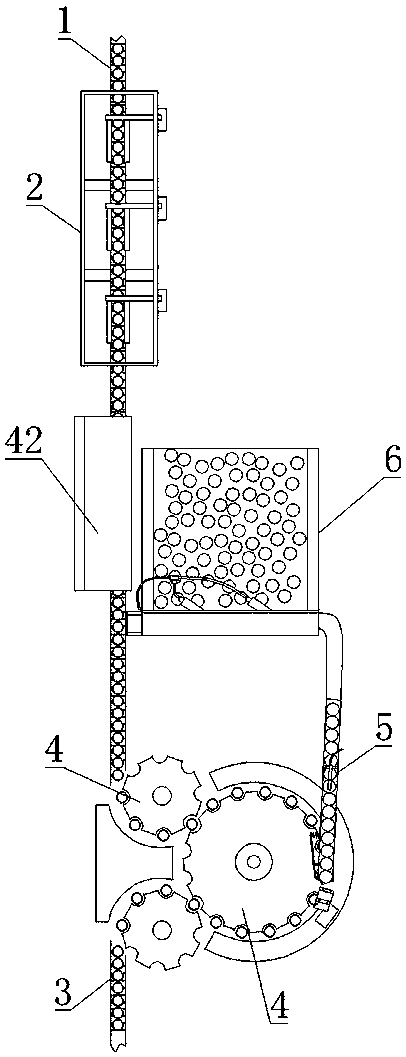

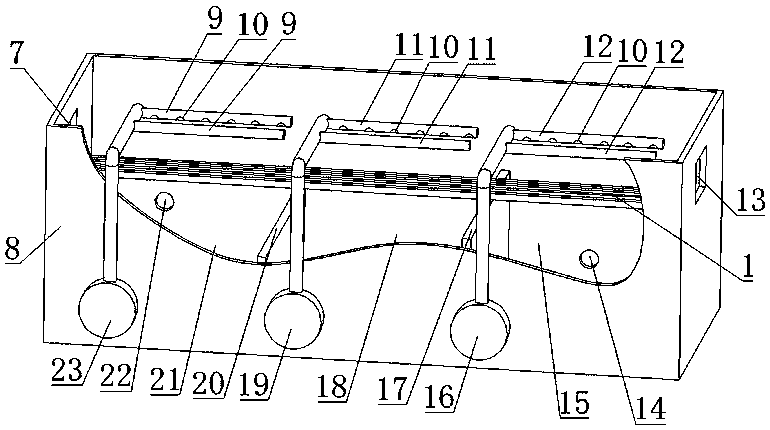

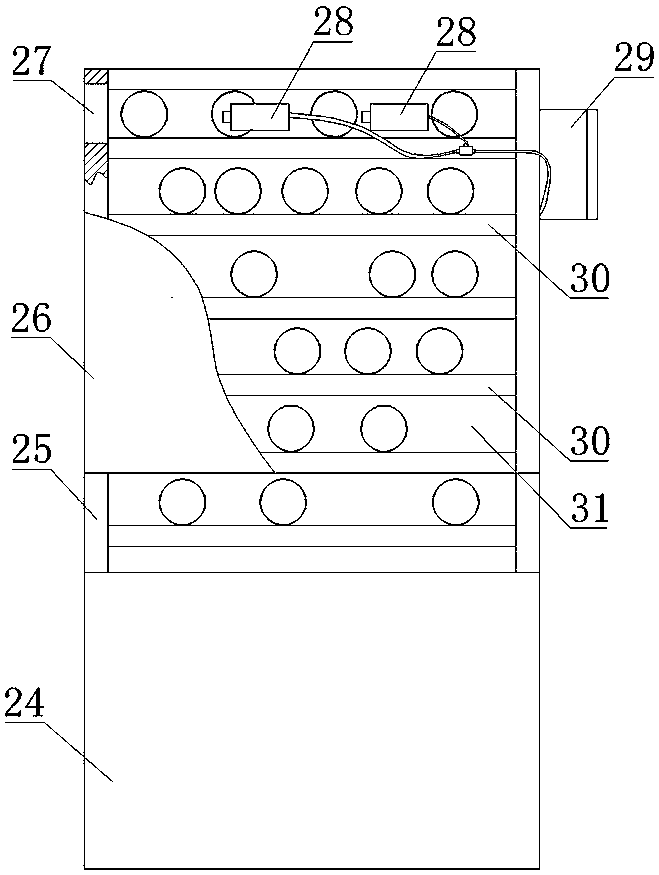

[0026]As shown in the figure, the condensed milk can packaging production line disclosed by the present invention includes a can conveying disc 4 set for continuous rotation, and the can conveying disc 4 is provided with a feeding station, a discharging station and an upper cover station , the feeding station is connected to the tank body feeding conveyor line 1, the tank body feeding conveyor line 1 passes through the water-saving tank washing mechanism 2 before reaching the tank body conveying disc 4, the discharging station is connected to the tank body sending conveyor line 3, and the upper The cover station is provided with a plastic cover automatic cover mechanism 5 . The plastic cover automatic capping mechanism 5 comprises a plastic cover conveying channel 35, the plastic cover conveying channel 35 is arranged obliquely, the top of the plastic cover conveyed on the plastic cover conveying channel 35 faces upward, and the discharge port of the plastic cover conveying cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com