Transmission equipment for dry kiln

A technology of transmission equipment and drying kiln, which is applied in the field of mechanical transmission, can solve the problems of easy aging, failure, and jamming of belts, achieve good impact resistance and extrusion resistance, reduce equipment failure rates, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose of the invention, technical solutions and beneficial effects of the present invention clearer, the embodiments of the present invention will be described below in conjunction with the accompanying drawings. The features in can be combined arbitrarily with each other.

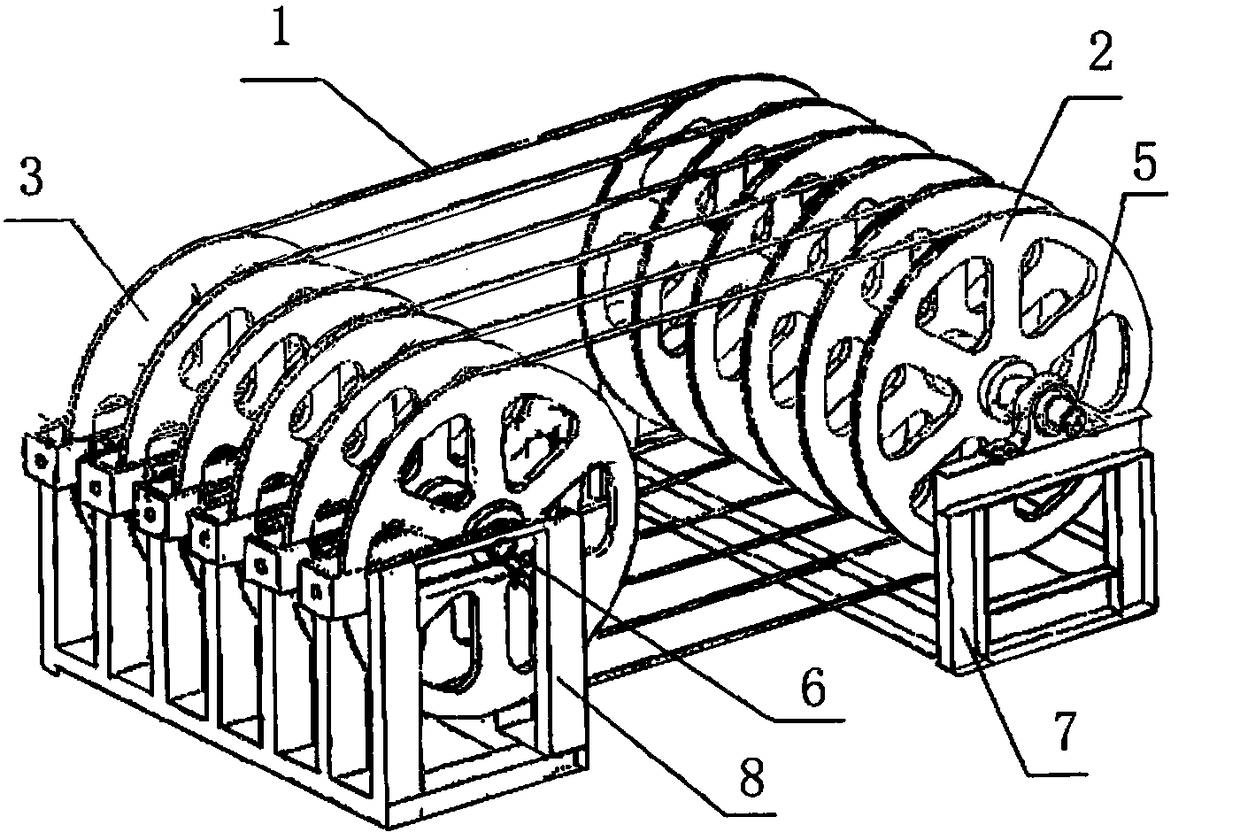

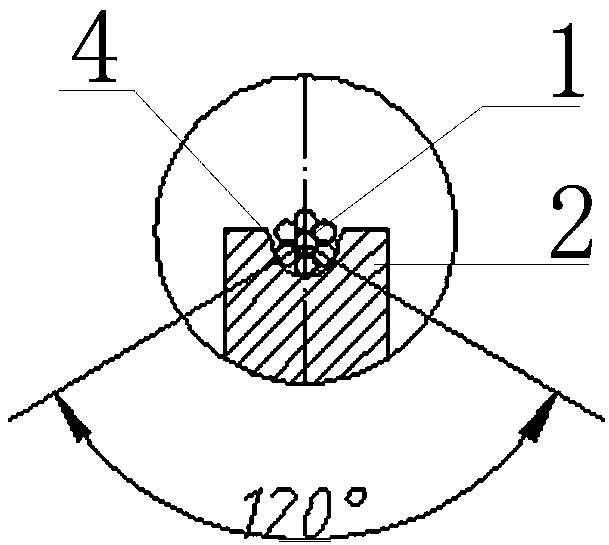

[0020] see figure 1 and figure 2 , a drying kiln transmission equipment for transporting mineral wool boards in the drying kiln, including a set of large pulleys 2, a set of driven pulleys 3 and ring-shaped metal cores with the same number as the large pulleys 2 and driven pulleys 3 The steel wire rope 1, the large pulley 2 and the driven pulley 3 are arranged in one-to-one correspondence, and a group of large pulleys 2 corresponding to each other and the driven pulley 3 are connected by the ring-shaped metal core steel wire rope 1, so Both the large pulley 2 and the driven pulley 3 are provided with accommodation grooves 4 on their circumferential surfaces, and the annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com