High-pressure check valve

A one-flow valve, high-pressure technology, applied in the direction of control valve, valve device, functional valve type, etc., can solve the problems of reduced spring stiffness coefficient, poor sealing performance of valve body, easy damage to valve body, etc., to achieve reasonable structural design, The effect of strong sealing performance and improved sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

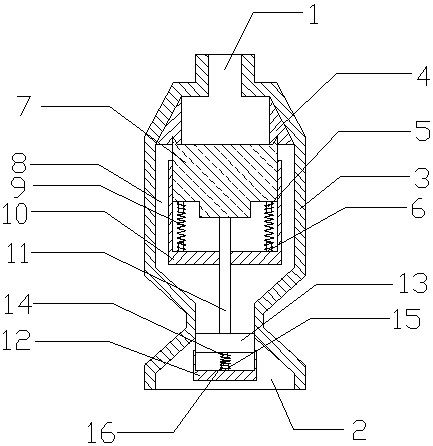

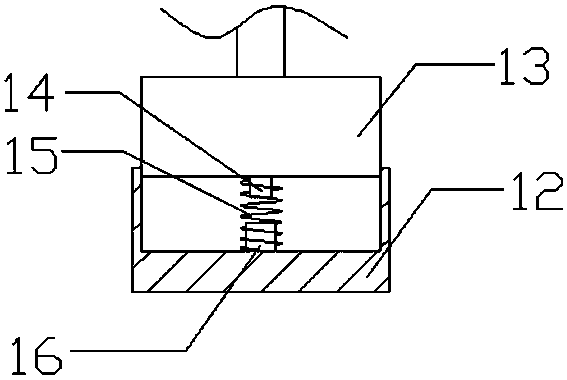

[0017] Example: such as Figure 1-2 As shown, it includes a valve body 3, one end of the valve body 3 is provided with a water inlet 1, and the other end is provided with a water outlet 2, one side of the water inlet 1 is provided with a gate seat 4, and one side of the gate seat 4 is provided A valve plug A7 is provided, and a first chute 10 is provided on one side of the valve plug A7, and a flow channel 8 is provided between the first chute 10 and the valve body 3, and a first fixing device is provided on the valve plug A7. pin 5, a second fixed pin 6 is arranged in the first chute 10, a spring A9 is connected between the first fixed pin 5 and the second fixed pin 6, and a connecting rod 11 is arranged at one end of the valve plug A7 The other end of the connecting rod 11 passes through the first chute 10 and is fixed to the valve plug B13, a second chute 12 is provided on one side of the valve plug B13, and a third fixing pin 14 is provided on the valve plug B13, A fourth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com