Crimping-type connector assembly hole model processing method

A model processing and connector technology, applied in the field of signal simulation, can solve the problems of difficult-to-press connector hole modeling and simulation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0011] It is easy to understand that according to the technical solution of the present invention, without changing the essential spirit of the present invention, those skilled in the art can imagine various implementations of the method for processing the crimp connector hole mold of the present invention. Therefore, the following specific embodiments and drawings are only exemplary descriptions of the technical solutions of the present invention, and should not be regarded as all of the present invention or as a limitation or limitation to the technical solutions of the present invention.

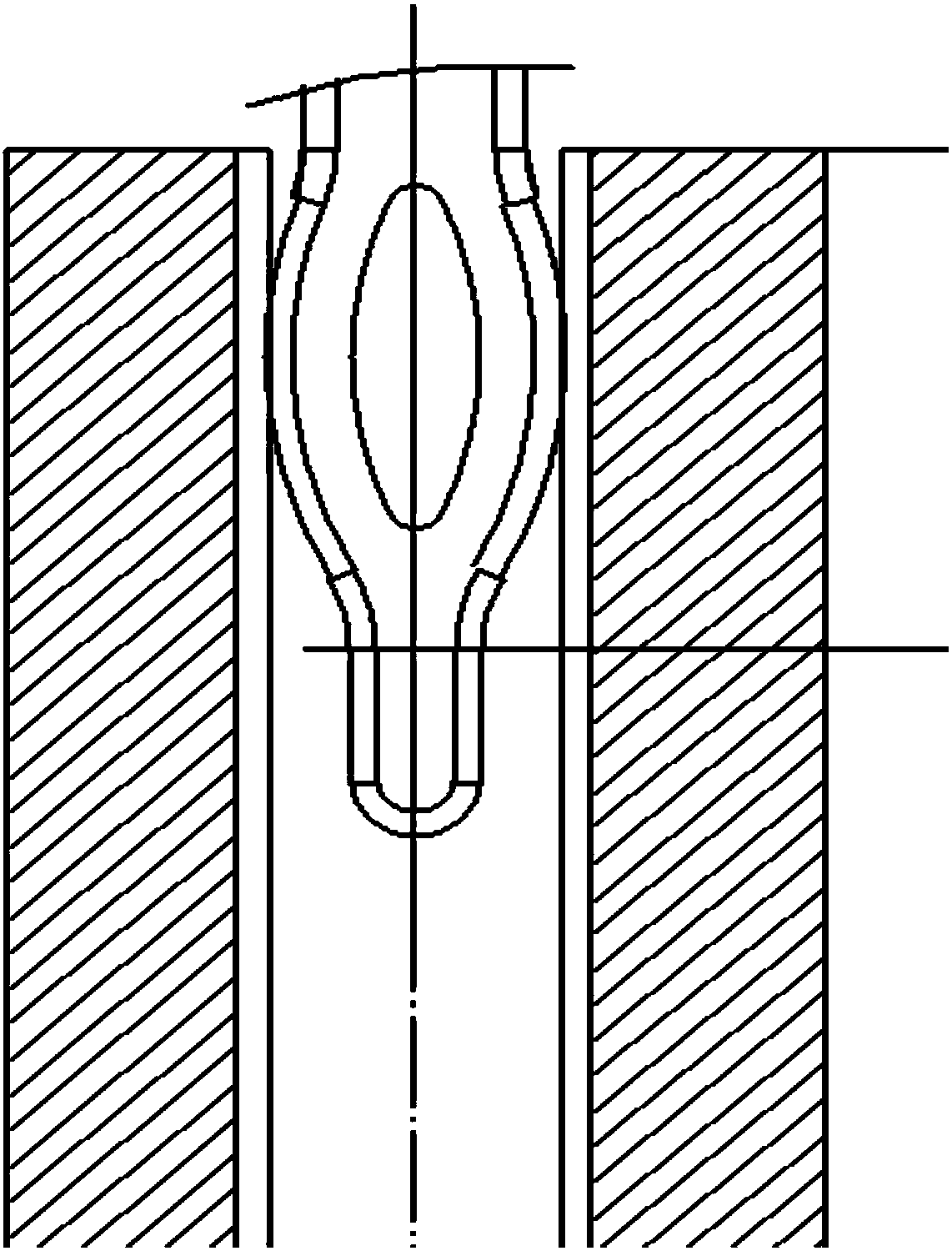

[0012] Such as figure 1 As shown, the contact point between the connector and the connector hole is a circular inner diameter of a certain height inside the connector hole, and this circular inner diameter is the input port under normal circumstances. However, because the circular inner diameter is inside the model, it is difficult to model the input port with software.

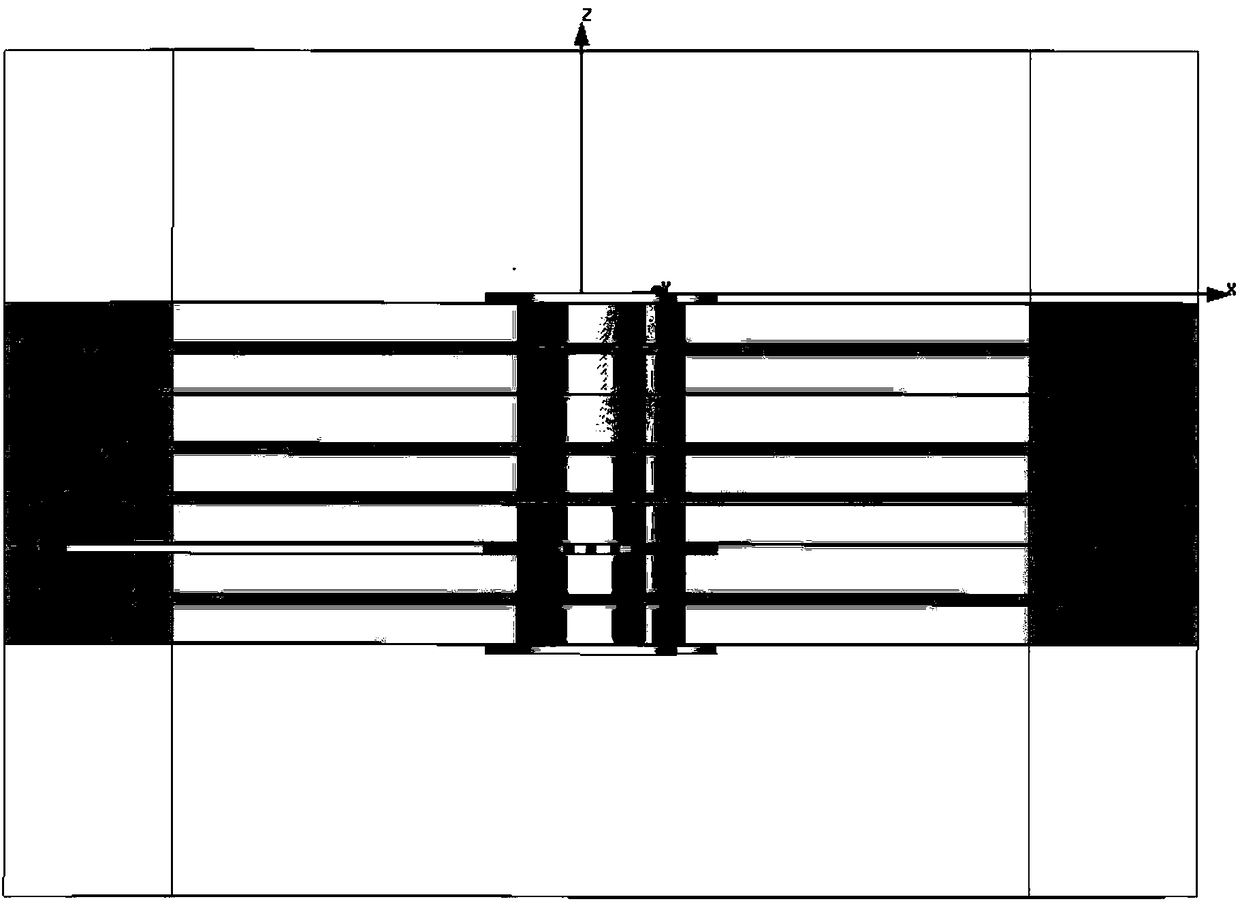

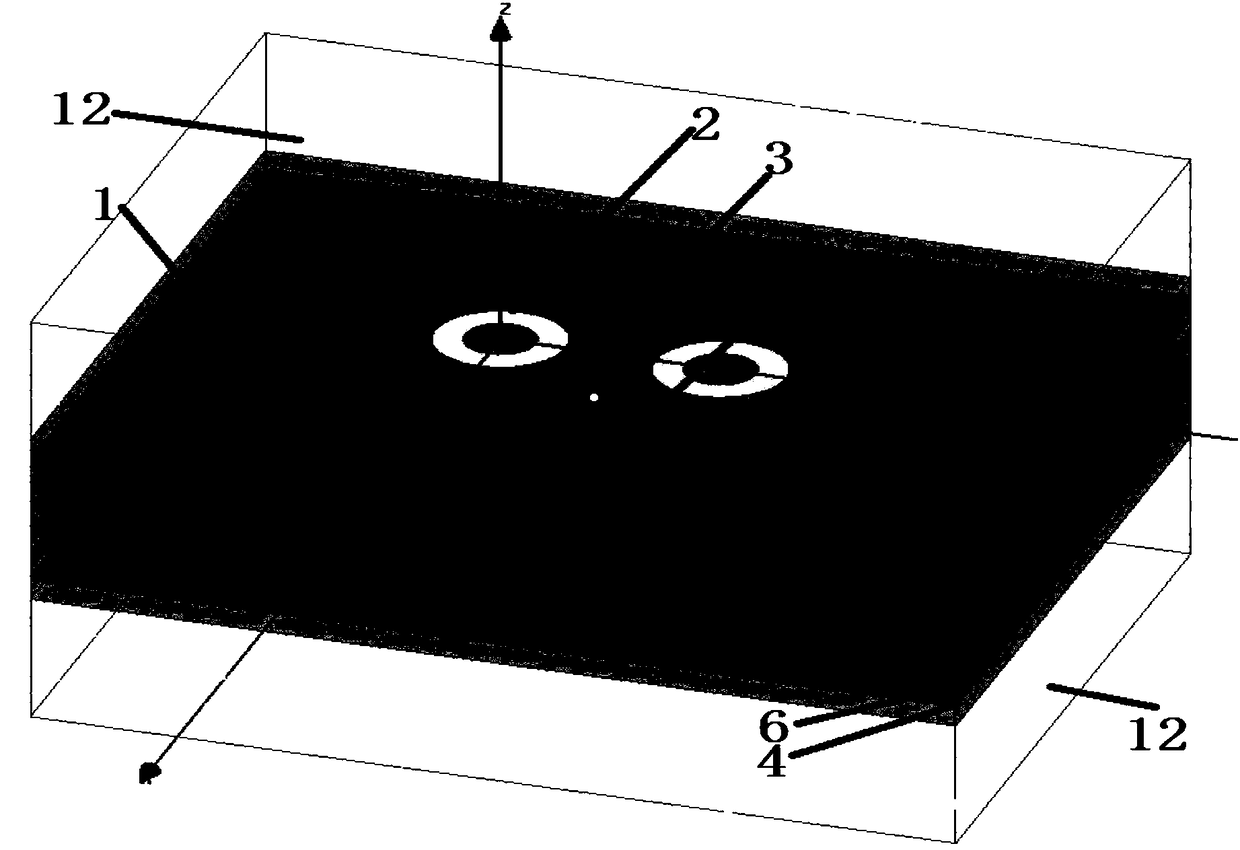

[0013] Such as figur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap