Tobacco leaf image quality evaluation method and system, storage, and electronic device

A quality evaluation and image quality technology, applied in image analysis, image data processing, instruments, etc., can solve the problems of poor stability and long time consumption, and achieve the effect of small calculation amount, excellent stability and short calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

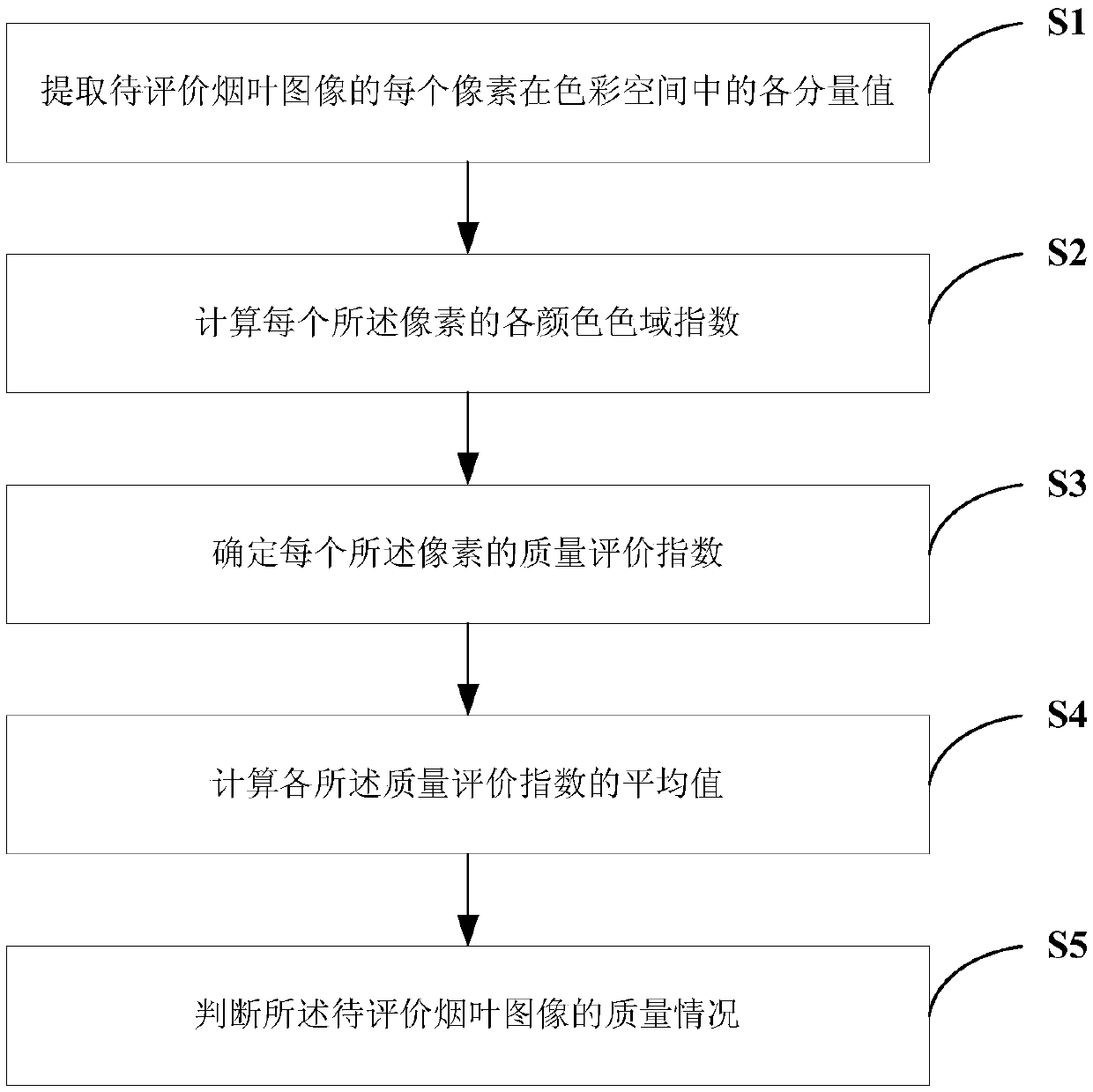

[0030] See figure 1 This embodiment provides a method for evaluating tobacco image quality with high stability and short calculation time, which mainly includes the following steps:

[0031] S1: Extract the component values of each pixel of the tobacco leaf image to be evaluated in the RGB color space.

[0032] It should be noted that the RGB color space here is a new color space converted from the traditional machine vision RGB (R, G, B) space according to RGB (R+G, 0.7B, 0.3B). As we all know, R, G, and B are red, green and blue spaces, and the basic color of the color theme of tobacco leaves is yellow. The character of yellow is determined by (R+G) / B. The larger the value, the closer the color is to yellow. So you need to split RGB into R+G and B during color conversion. In addition, because the B value is also an indicator of the brightness of the shooting environment, the B value also has a certain meaning, so the B value also needs to be converted separately. The final co...

Embodiment 2

[0042] according to figure 1 The method flow shown is figure 2 To evaluate the quality of tobacco leaf images, the specific steps are as follows:

[0043] Step 1: Extract the component values in the RGB color space of each pixel of the tobacco leaf image to be evaluated:

[0044] When i=1: R 1 =RGB(1,1)=336.22; G 1 =RGB(1,2)=22.32; B 1 =RGB(1,3)=9.56.

[0045] When i=2: R 2 =RGB(2,1)=310.37; G 2 =RGB(2,2)=22.89; B 2 =RGB(2,3)=9.76.

[0046] When i=3: R 3 =RGB(3,1)=325.22; G 3 =RGB(3,2)=23.13; B 3 =RGB(3,3)=9.32.

[0047] ………………

[0048] When i=n: R n =RGB(n,1)=325.22; G n =RGB(n,2)=23.76; B n =RGB(n,3)=9.18.

[0049] Step 2: Solve the color gamut index of each pixel of the tobacco leaf image to be evaluated:

[0050] When i=1: CGIR 1 =R 1 / (G 1 +B 1 ) = 10.546; CGIG 1 =G 1 / (R 1 +B 1 ) = 0.0645; CGIB 1 =B 1 / (R 1 +G 1 )=0.02941.

[0051] When i=2: CGIR 2 =R 2 / (G 2 +B 2 ) = 9.506; CGIG 2 =G 2 / (R 2 +B 2 ) = 0.0715; CGIB 2 =B 2 / (R 2 +G 2 )=0.02852.

[0052] When i=3: CGIR 3 =R 3 / (G 3 +B ...

Embodiment 3

[0066] use figure 1 The method flow shown, right Figure 3a~3d The quality of the four tobacco leaf images is evaluated and sorted, and the quality evaluation of each tobacco leaf image is obtained The values and their sorting are shown in Table 1. visible, Figure 3d of The value is the largest, and the ranking is first, indicating that the quality of the tobacco leaf image is the best; Figure 3b of The smallest value indicates that the quality of the tobacco leaf image is the worst. Actually, Figure 3d For high-quality camera + high-quality light source conditions to capture images, and Figure 3b It can be seen that the quality evaluation result given by the present invention is also in line with the subjective perception and actual objective factors of human vision.

[0067] Table 1

[0068]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com