Manufacture method of novel arm-type folding shield

A manufacturing method and technology of shields, which can be applied to defensive objects and other directions, and can solve problems such as inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

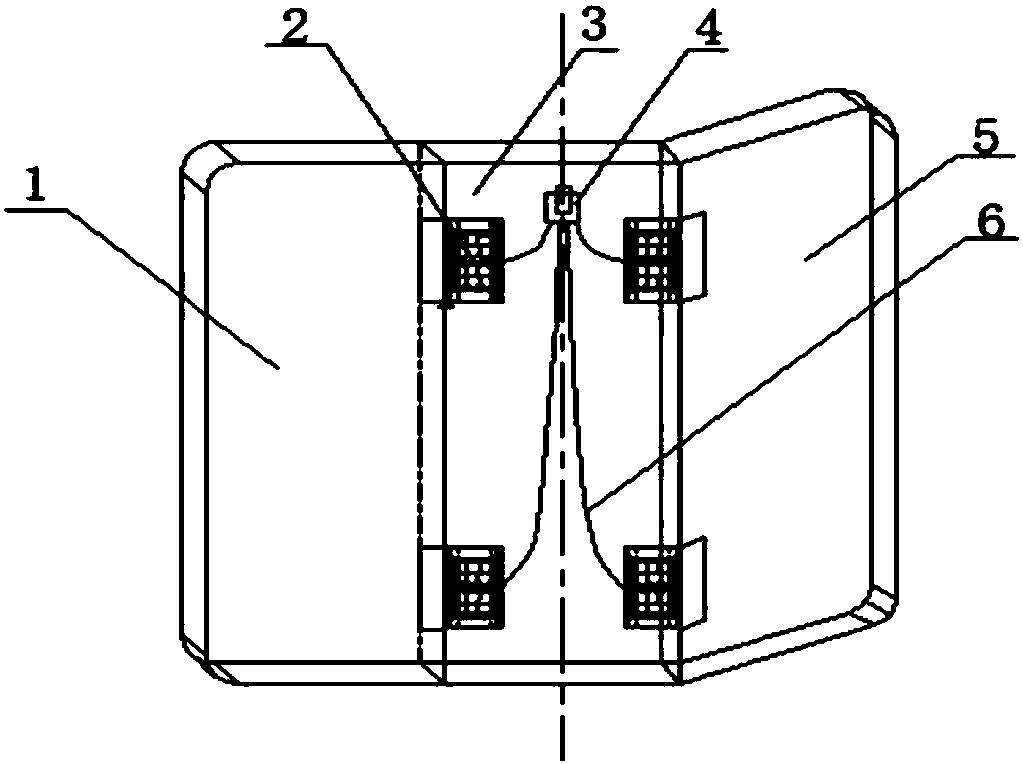

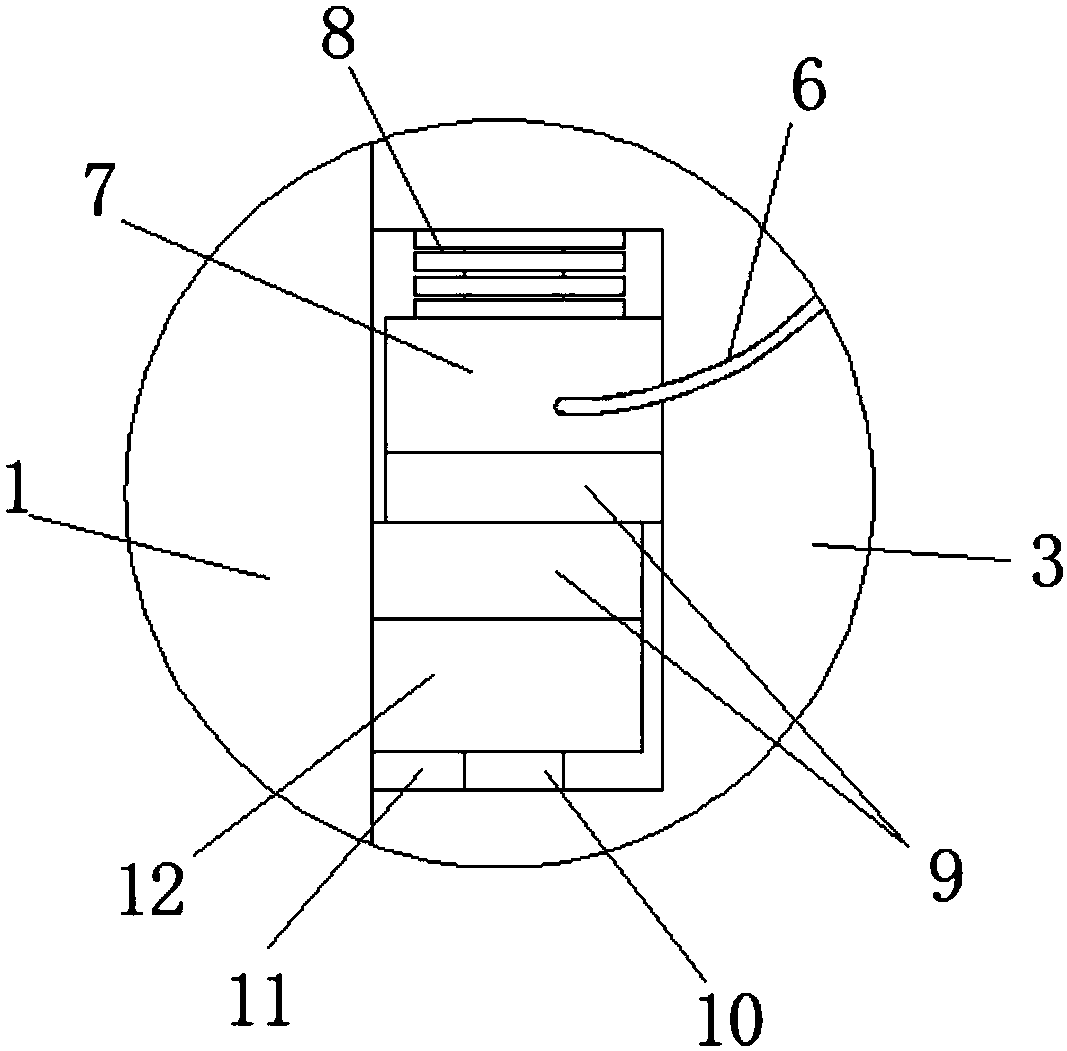

[0019] refer to Figure 1-2 , a novel arm type folding shield manufacturing method, comprising the following steps:

[0020] S1. Manufacture of left panel 1, middle panel 3, and right panel 5: a single-layer UD cloth is synthesized from multiple unidirectional parallel and compact high-strength and high-modulus polyethylene fiber monofilaments after dipping, and is laminated and molded at 0° / 90°. plate; the corners of the left panel 1 and the right panel 5 are arc angles. The middle panel 3 has a size of 45x14cm; the middle panel 3 is symmetrically arranged with a left panel 1 with a size of 45x14cm and a right panel 5 with a size of 45x10cm.

[0021] S2. Using a c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap