Buffer device of belt conveyor carrier roller

A belt conveyor and buffer device technology, which is applied to conveyor objects, transportation and packaging, roller columns, etc., can solve the problems of affecting the work progress, poor sealing effect of the rollers, and short service life of the rollers, so as to reduce the cost and consumption. , Improve the sealing effect, improve the effect of lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

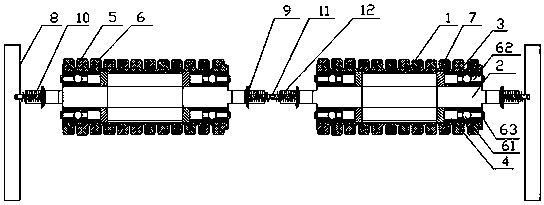

[0020] Such as figure 1 As shown, a buffer device for a belt conveyor roller, including a roller body 1, a roller shaft 2, a bearing seat 3, a bearing 4, a sealing layer 5, an oil seal device 6, a support frame 8 and a buffer device 10; The supporting frame 8 is two on the left and right, and several idler roller bodies 1 are connected between the two supporting frames 8; bearing housings 3 are arranged on both sides of the idler roller body 1; bearings 4, sealing layer 5 and oil seal device 6 are installed in the bearing housing 3, and the sealing layer 5 covers the bearing 4 and the oil seal device 6; the idler shaft 2 runs through the middle of the idler roller body 1 and is connected with the bearing housing 3; the buffer device 10 is installed on the idler shaft 2 The buffer device 10 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com