Trash remover control system capable of achieving accelerated descending and increasing underwater penetration

A technology of control system and cleaning machine, which is applied in the cleaning of open water surface, clockwork mechanism, water conservancy projects, etc. It can solve the problems of increasing the descending depth of the cleaning machine and the effect is not obvious, so as to solve the problem of low grabbing efficiency , Solve the effect of small grasping depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples, but not as a limitation of the present invention. The specific implementation, structure and features provided according to the present invention are described in detail as follows:

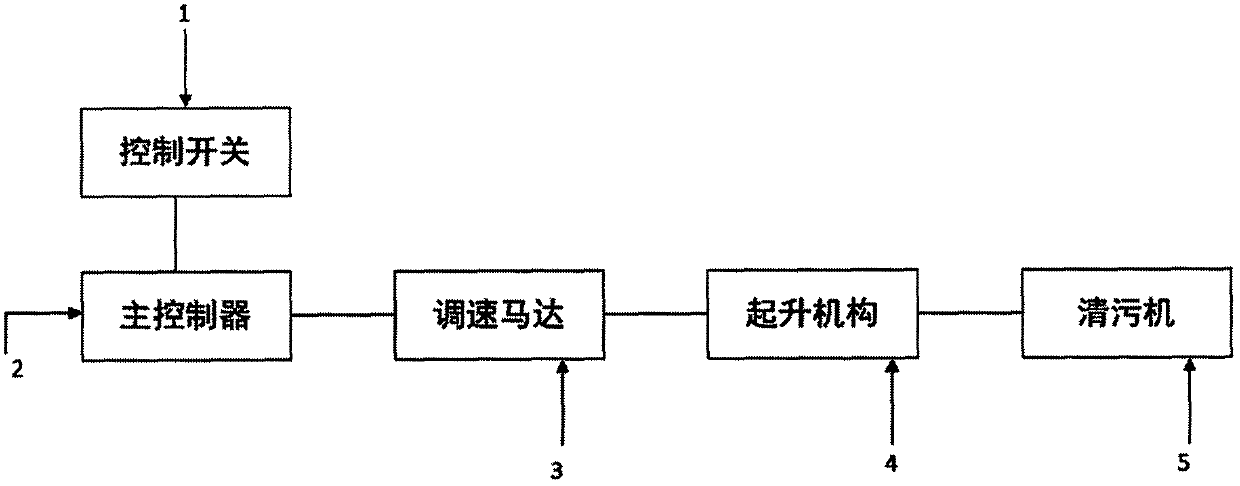

[0019] Such as figure 1 As shown, the cleaning machine control system that accelerates the descent to increase the water entry depth includes a control switch 1, a main controller 2, a speed regulating motor 3, a lifting mechanism 4 and a cleaning machine 5.

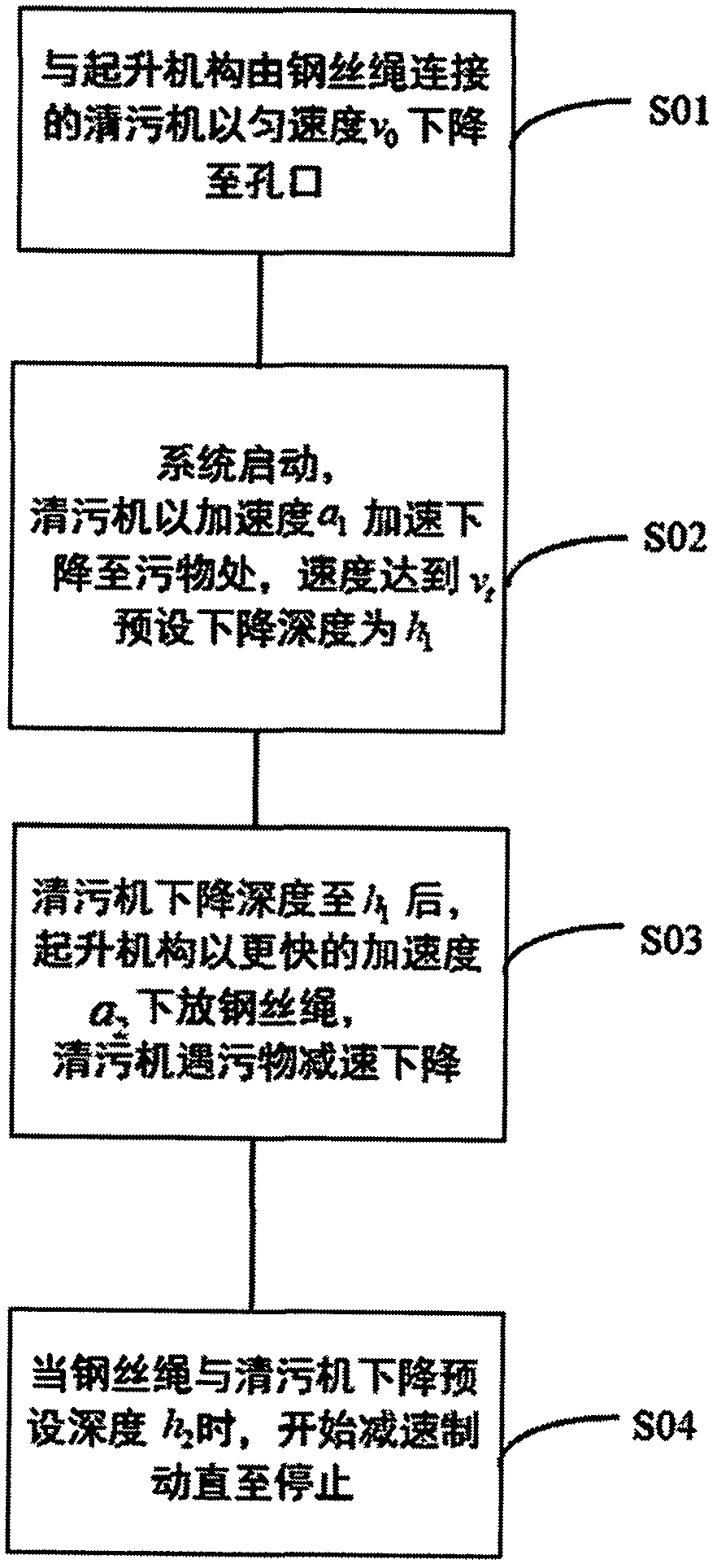

[0020] Such as figure 2 As shown, the cleaning machine control system that accelerates the descent and increases the water entry depth is used to control the speed at which the cleaning machine 5 descends. It is characterized in that the method includes:

[0021] S01: The cleaning machine 5 connected with the hoisting mechanism 4 by a wire rope runs at a uniform speed v 0 down to the orifice;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com