A pcb board fixing device for a small mounter

A PCB board and fixing device technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of PCB board installation difficulty, low PCB board applicability, installation dead angle, etc., to improve working stability and service life, and improve fixing stability Sex, to avoid the effect of force deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

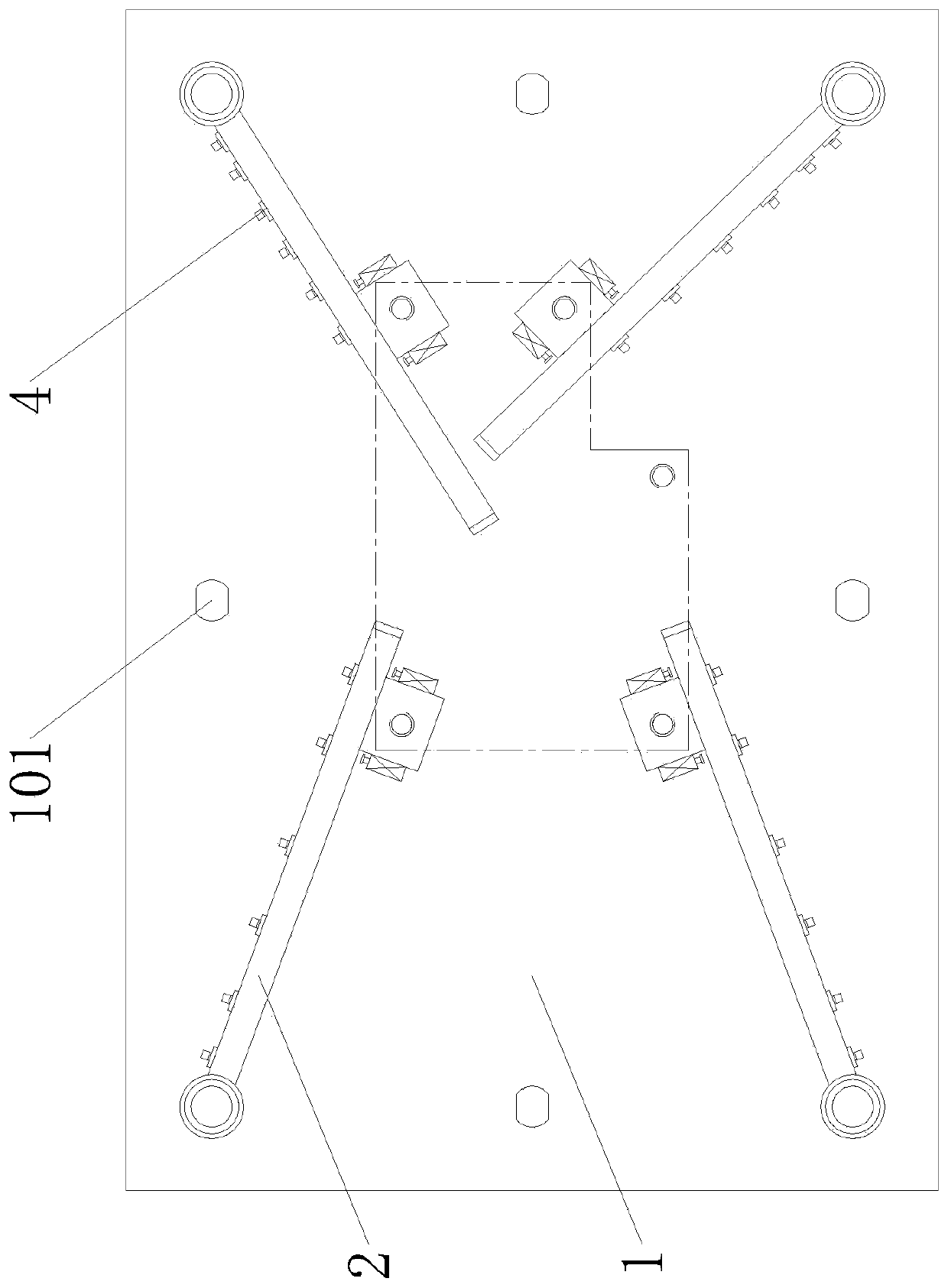

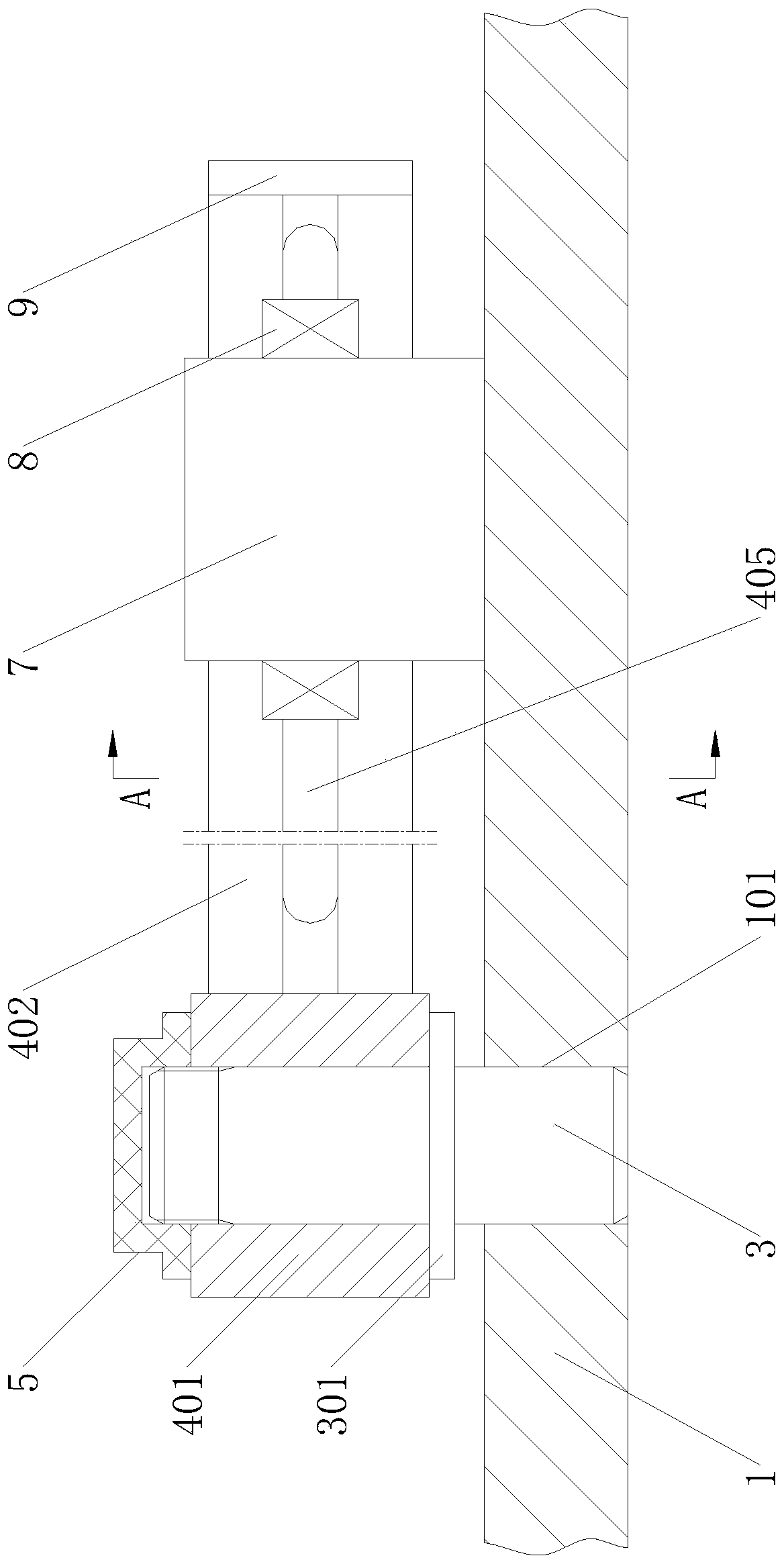

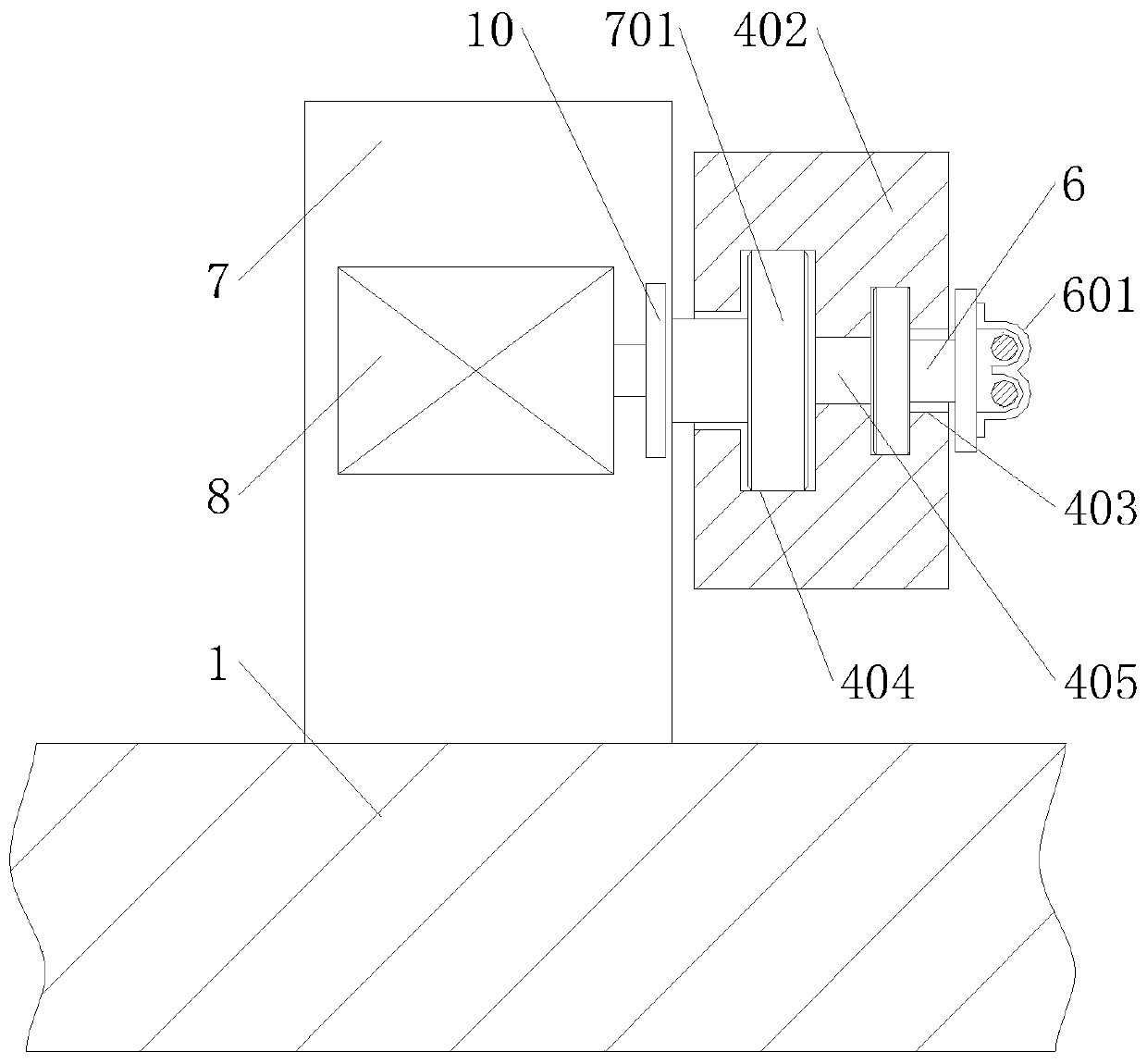

[0016] Example. A PCB board fixing device for a small chip mounter, which consists of figure 1 As shown, the bottom plate 1 is included, and the bottom plate 1 is provided with a plurality of fixed seat groups 2. The fixed seat group 2 includes a fixed shaft 3, the lower end of the fixed shaft 3 is connected to the bottom plate 1, and a rotating arm 4 is connected to the fixed shaft 3 for rotation. The rotating arm 4 includes a rotating cylinder 401. The bottom of the rotating cylinder 401 is provided with a limit plate 301 located outside the fixed shaft 3. The top of the rotating cylinder 401 is provided with a locking cover 5 connected to the fixed shaft 3. The outer wall of the rotating cylinder 401 is One side is provided with an arm body 402, and the two sides of the arm body 402 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com