Stretching device for stretching film of synthetic material at least in transverse direction

一种拉伸装置、合成材料的技术,应用在拉伸装置领域,能够解决生产速度降低等问题,达到减小磨损速率、良好引导、限制产品损失的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

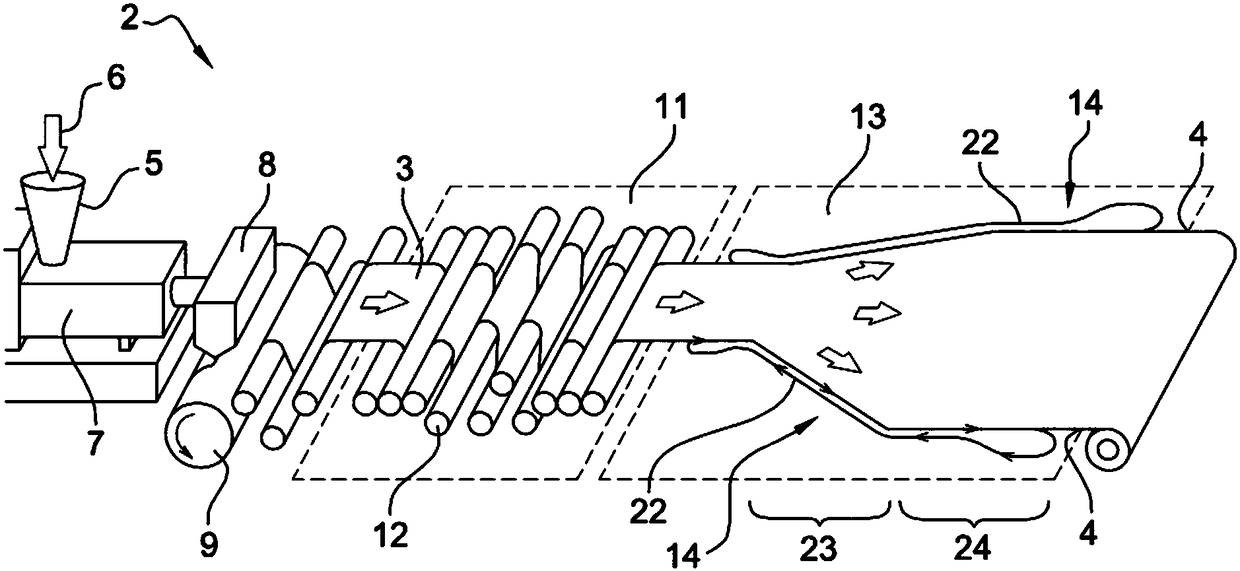

[0089] figure 1 A production device 2 is shown for producing a film 3 made of synthetic material with two substantially parallel longitudinal edges 4 .

[0090] The production facility 2 comprises in turn:

[0091] - Synthetic material 6 supply system 5,

[0092] - an extruder 7, allowing a controlled supply of synthetic material 6,

[0093] - a system 8 for melting synthetic materials 6,

[0094] - a casting drum 9 on which the film 3 is formed by the outflow of the molten synthetic material 6,

[0095] - a longitudinal stretching system 11 for stretching the film 3 in the longitudinal direction, the longitudinal stretching system 11 comprising differential speed (speed difference) rollers 12 to carry and stretch the film 3, and

[0096] - A stretching system 13 for stretching the film 3 at least in the transverse direction.

[0097] This stretching system 13 comprises an oven (not represented in the figure) allowing the temperature of the film 3 to be adjusted during it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com